Helmet cleaning machine and operation method thereof

An operation method and cleaning machine technology, applied to cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as lack of cleaning equipment, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

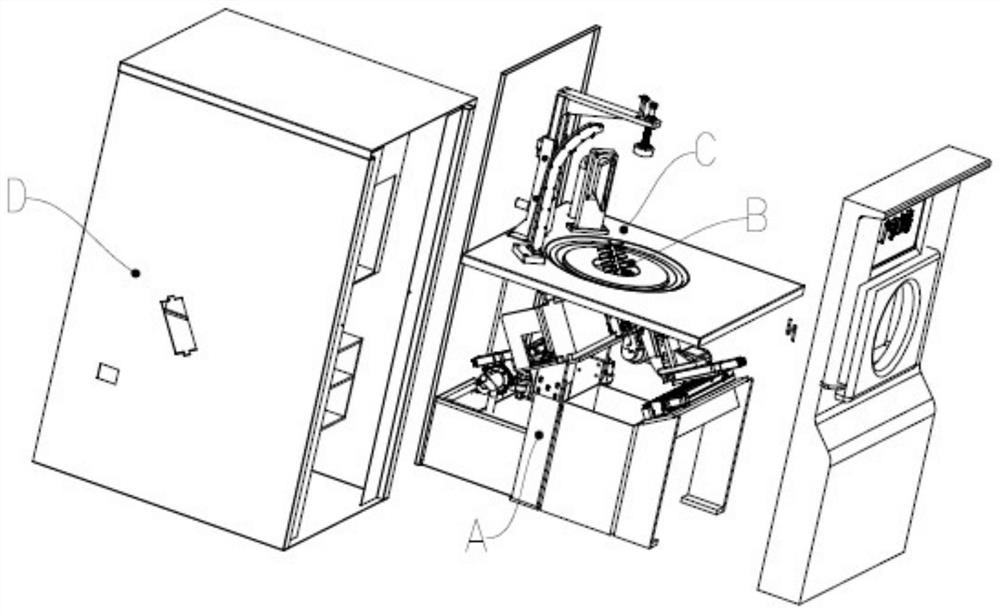

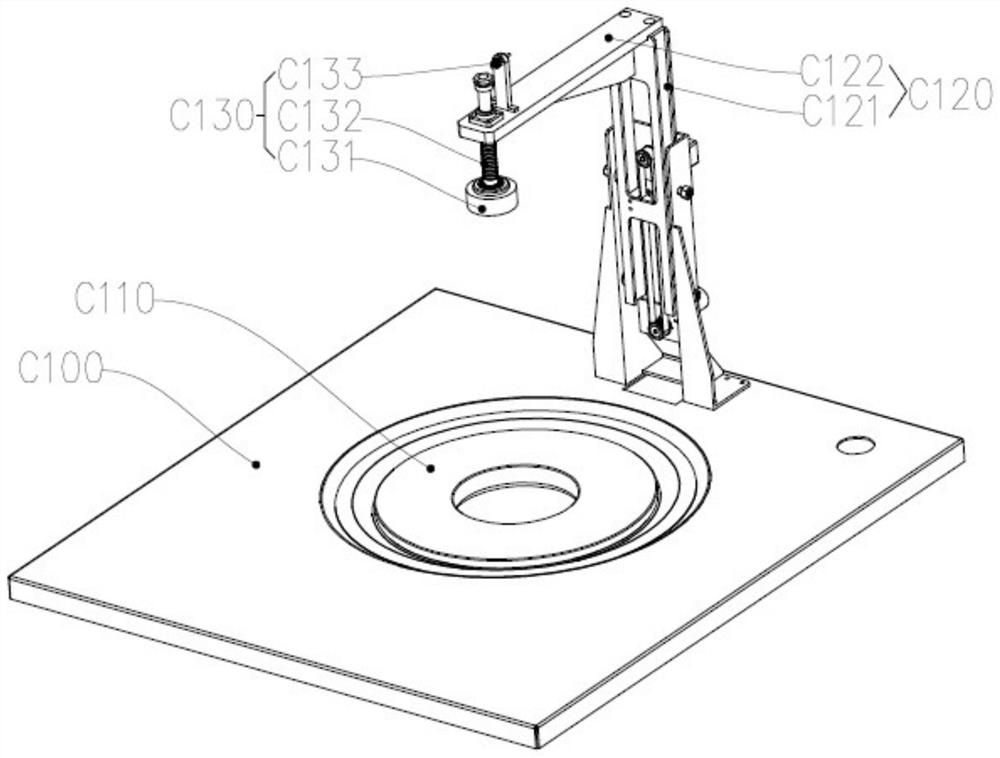

[0058] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

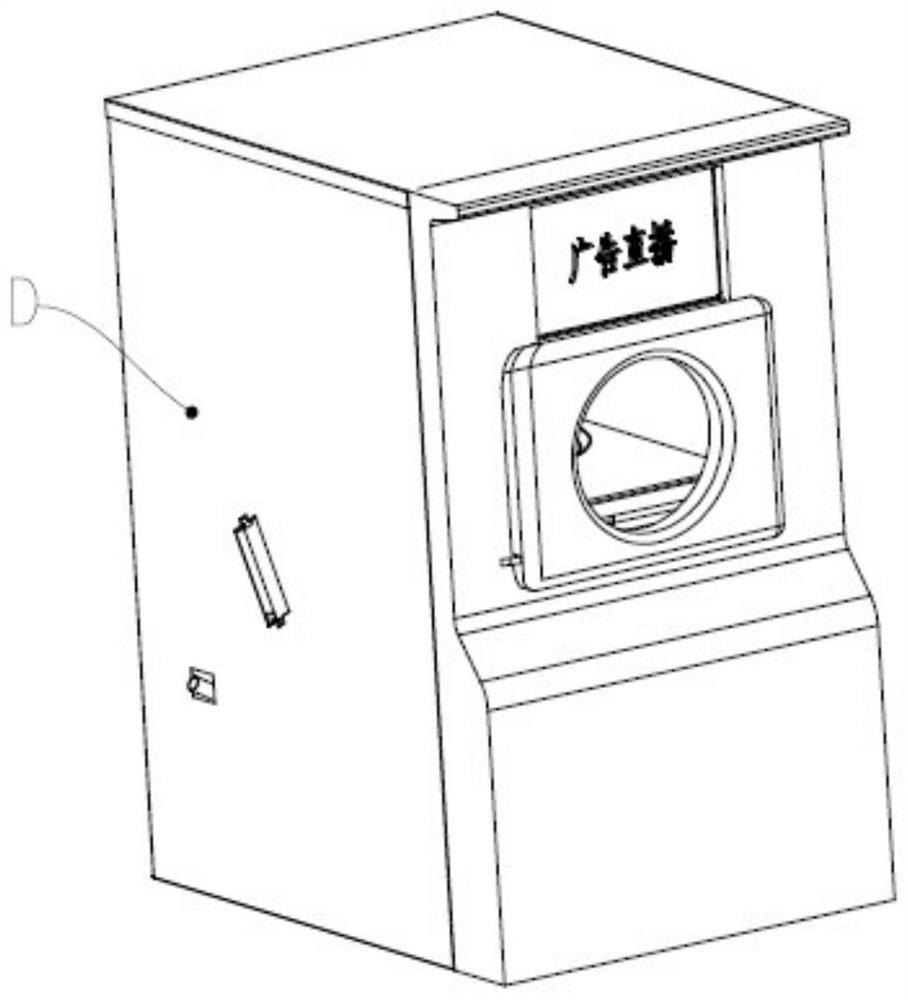

[0059] Such as Figure 1-10 Shown, a kind of operation method of helmet washing machine is characterized in that, comprises the steps:

[0060] A. Clean the outer surface. The photoelectric switch in the cleaning chamber detects that there is a helmet restrained on the rotating tray. The rotating tray drives the helmet to rotate clockwise. The high-pressure atomizing water spray device sprays atomized cleaning with cleaning function on the outer surface of the helmet water;

[0061] B. After drying the outer surface and cleaning the outer surface of the cleaned helmet within a certain period of time, the high-pressure atomizing water spray device stops spraying water, the rotating seat continues to rotate, and the air blowing device blows the high-pressure airflow in a fan shape. On the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com