Full-automatic cleaning and drying device for badminton feathers

A fully automatic cleaning and drying device technology, which is applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of difficult drying process and difficult cleaning, and achieves easy follow-up collection, high work efficiency, and cleaning good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

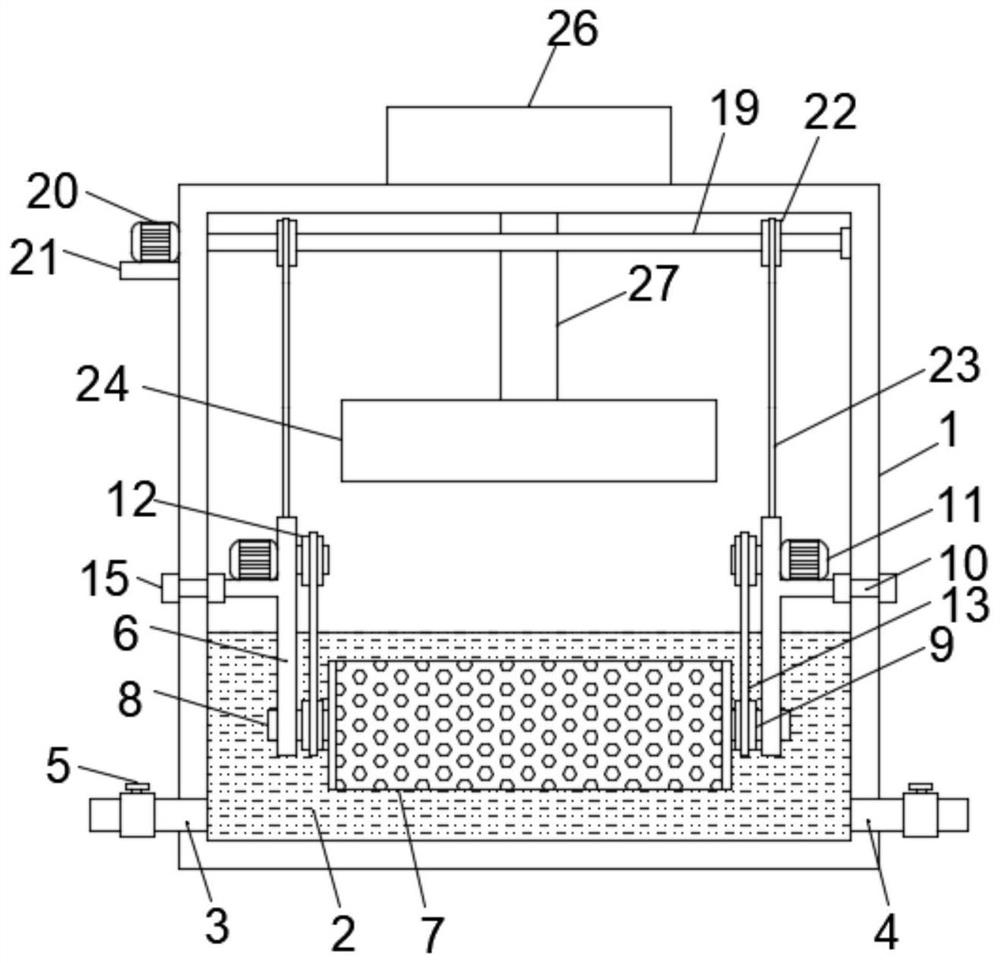

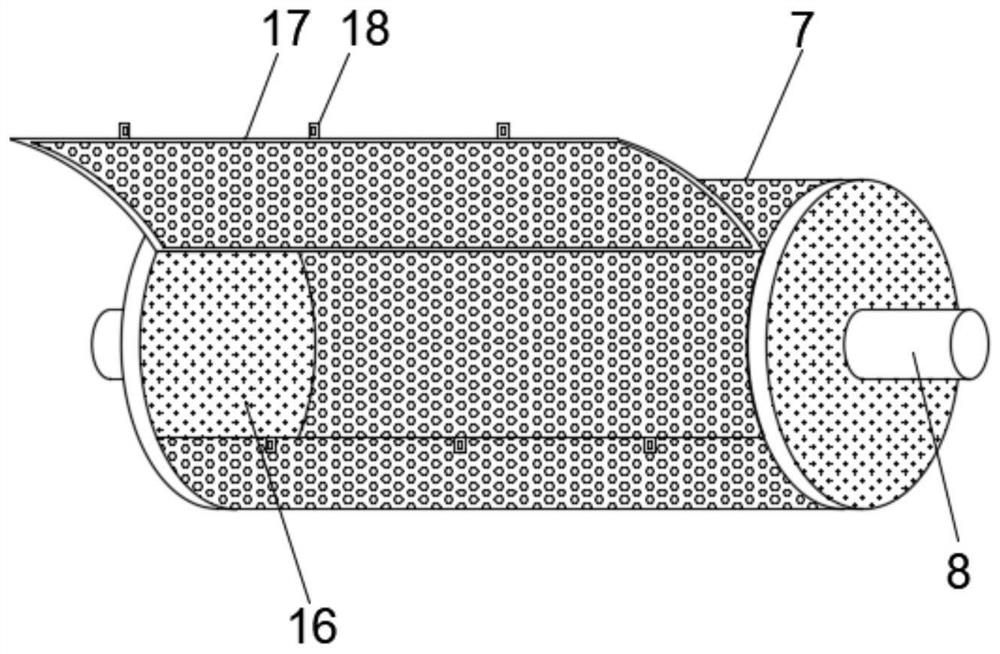

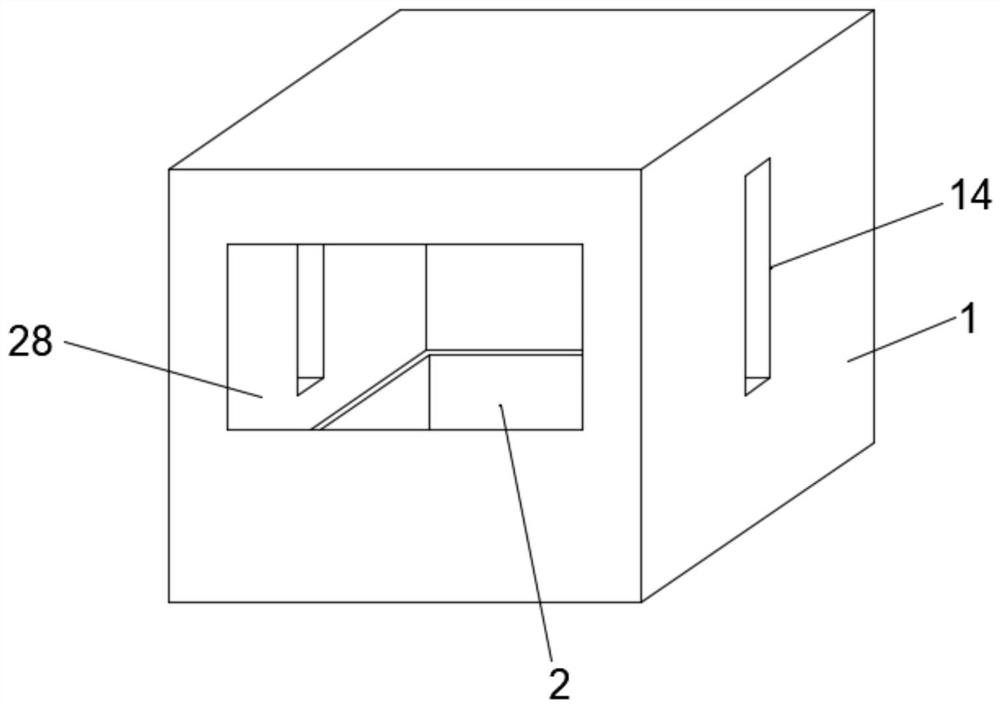

[0026] Example 1: See Figure 1-6 , providing a technical solution for the present invention: a fully automatic cleaning and drying device for badminton feathers, comprising a cleaning box 1 and a cleaning pool 2, a drum 7 and a drying cover 24 arranged in the cleaning box 1; the cleaning pool 2 It is arranged at the bottom position in the cleaning box 1, and two vertical lifting brackets 6 are arranged in parallel in the cleaning box 1, and the roller 7 is installed between the lower ends of the two lifting brackets 6 by rotating the rotating shaft 8 welded at its two ends; A driven gear 9 is respectively fixedly installed on the rotating shaft 8 at the end, and the upper end of the two lifting brackets 6 phase backs is provided with a guide plate 10 vertically inserted into the side wall of the cleaning box 1, the first drive motor 11 is installed on the guide plate 10, the first drive motor The output shaft of 11 is equipped with the driving gear 12 placed directly above th...

Embodiment 2

[0036] Example 2: See figure 1, is the position of the cylinder 7 in the cleaning state; the second driving motor 20 is started, and the rotating rod 19 is rotated so that the stay cord 23 on the winding roller 22 is loosened, and the lifting bracket 6 descends (the guide plate 10 is inserted into the guide groove 14 to slide, At the same time, the two limit blocks 15 limit the guide plate 10 to prevent it from shaking left and right, ensuring the stable lifting of the drum 7), driving the drum 7 to sink into the cleaning pool 2; liquid (or clear water), so that the liquid surface is not over the drum 7, start the first drive motor 11, under the transmission action of the transmission chain belt 13, drive the drum 7 to rotate, fully stir the feathers, and impact contact with the cleaning liquid, the cleaning effect is good ; It can be cleaned 2-3 times, and after each cleaning, the sewage is discharged by the outlet pipe 4 (it can be discharged into the water treatment and pur...

Embodiment 3

[0037] Example 3: See Figure 6 , is the position of the cylinder 7 in the drying state; after the cleaning is completed, the second drive motor 20 starts, and the rotating rod 19 rotates in the opposite direction, so that the stay rope 23 on the winding roller 22 is recovered, and the elevating bracket 6 rises, and the cylinder 7 Pull out the cleaning tank 2 and put it in the drying cover 24. During the process of pulling out the cleaning tank 2, the mesh structure of the drum 7 can drain water quickly; When blowing air into the cylinder 7, the first drive motor 11 is started, which drives the cylinder 7 to rotate slowly, and the feathers inside are flipped, so that the feathers can be dried quickly and the work efficiency is high.

[0038] After the drying is completed, the cylinder 7 resets and is placed at the position facing the operation window 28. At this time, the material guide port 16 is placed on the bottom surface of the cylinder 7 to facilitate the export of feath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com