Plate bending equipment for metal pool production

A pool and plate technology, which is applied in the field of plate bending, can solve the problems of inconsistent bending angles of plates, uneven stress of plates, and low degree of automation, so as to avoid inconsistent bending angles, high degree of automation, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

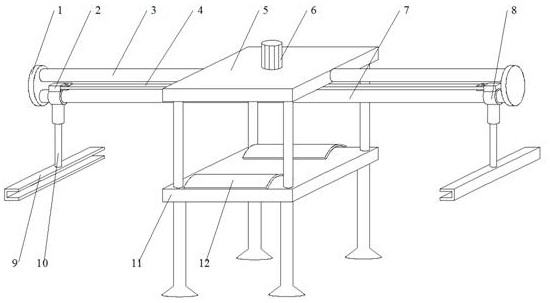

[0025] refer to Figure 1-2 , a metal pool production plate bending equipment, including a workbench 11, the four corners of the bottom of the workbench 11 are welded with support columns, both sides of the top of the workbench 11 are connected with splints 12 by elastic hinges, the top four corners of the workbench 11 Columns are all welded, and the same top plate 5 is welded on the top of the columns. The top plate 5 is provided with a reciprocating mechanism, the bottom of the reciprocating mechanism is provided with a bending mechanism, and a fixed structure is provided between the reciprocating mechanism and the top plate 5.

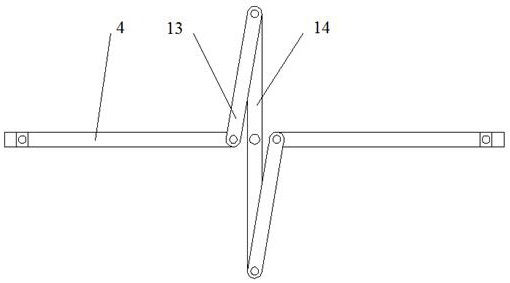

[0026] In the present invention, the reciprocating mechanism includes the first positive and negative motor 6, the rotating rod 14, the first connecting rod 13, the second connecting rod 4, the connecting block 2, the limit post 7 and the first collar 8, the first positive and negative motor 6 is installed on the top of the top plate 5, the output s...

Embodiment 2

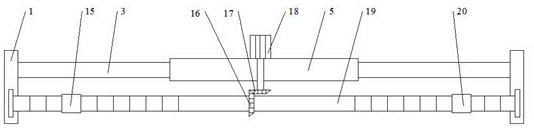

[0029] refer to image 3 The only difference between this embodiment and Embodiment 1 is that the reciprocating mechanism includes a second reversible motor 18, a screw mandrel 19, a second collar 15, a second bevel gear 16, a first bevel gear 17 and a third collar 20 , the second reversible motor 18 is installed on the top of the top plate 5, the output shaft of the second reversible motor 18 runs through the top plate 5 and is welded with the first bevel gear 17, the first bevel gear 17 is meshed with the second bevel gear 16, the second The center of the second bevel gear 16 runs through a threaded mandrel 19, and the two ends of the threaded mandrel 19 are respectively sleeved with a second collar 15 and a third collar 20. The end of the threaded mandrel 19 where the second collar 15 is located is provided with a positive thread, and the second collar 15 is provided with a positive thread. The inner wall of the second collar 15 is provided with a reverse thread, the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com