Hygienic material and processing method thereof

A technology of hygienic materials and processing methods, applied in the field of hygienic materials, can solve the problems of long time, long cycle, hidden safety hazards, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

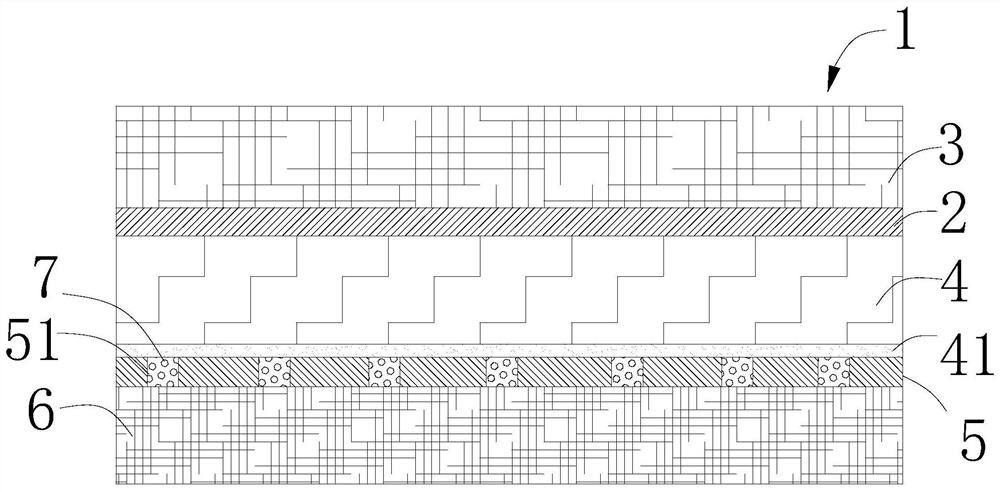

[0032] Such as figure 1 As shown, a sanitary material of the present invention includes a composite body 1 welded by ultrasonic vibration. The composite body 1 is sequentially provided with a first material layer 4 and a second material layer 6 from top to bottom. The bottom surface of the first material layer 4 is rough Face 41. The first material layer 4 is a synthetic resin layer, and the second material layer 6 is a polyester non-woven fabric layer.

[0033] The new processing method of the hygienic material is:

[0034] (1) The bottom surface of the first material layer 4 is mechanically scraped, such as using sandpaper, a grinding wheel, etc. to gently scrape until the surface of the non-woven fabric is fluffed or the surface of the synthetic resin layer has obvious scratches, that is, the rough surface 41 is formed;

[0035] (2) Lay the first material layer 4 and the second material layer 6 processed by the above steps overlappingly, the rough surface 41 is the contac...

Embodiment 2

[0046] Such as figure 1 As shown, a sanitary material of the present invention includes a composite body 1 welded by ultrasonic vibration, and the composite body 1 is sequentially provided with a third material layer 2, a second resin film layer 3, a first material layer 4, a A resin film layer 5 and a second material layer 6, the melt index of the second resin film layer 3 is greater than that of the first resin film layer 5, the bottom surface of the first material layer 4 is a rough surface 41, and the first resin film layer 5 is provided with a conductive In the holes 51 , nano zinc oxide particles 7 are scattered between the first material layer 4 and the second material layer 6 . The section of the energy guiding hole 51 is rectangular. Both the second resin film layer 3 and the first resin film layer 5 are low-melting finger resins. The first material layer 4 is a synthetic resin layer, the third material layer 2 is a polypropylene non-woven fabric layer, and the seco...

Embodiment 3

[0054] Such as figure 1 As shown, a sanitary material of the present invention includes a composite body 1 welded by ultrasonic vibration, and the composite body 1 is sequentially provided with a third material layer 2, a second resin film layer 3, a first material layer 4, a A resin film layer 5 and a second material layer 6, the melt index of the second resin film layer 3 is greater than that of the first resin film layer 5, the bottom surface of the first material layer 4 is a rough surface 41, and the first resin film layer 5 is provided with a conductive In the holes 51 , nano zinc oxide particles 7 are scattered between the first material layer 4 and the second material layer 6 . The section of the energy guiding hole 51 is semicircular. Both the second resin film layer 3 and the first resin film layer 5 are low melting finger resins. The first material layer 4 is a synthetic resin layer, the third material layer 2 is a polypropylene non-woven fabric layer, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com