Optical fiber fusion connector and method

An optical fiber fusion and connector technology, applied in the field of optical fibers, can solve the problems of difficult optical fiber fusion coupling, high power density, laser damage, etc., and achieve the effect of improving the end face damage threshold, efficient fusion, and reducing the end face reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

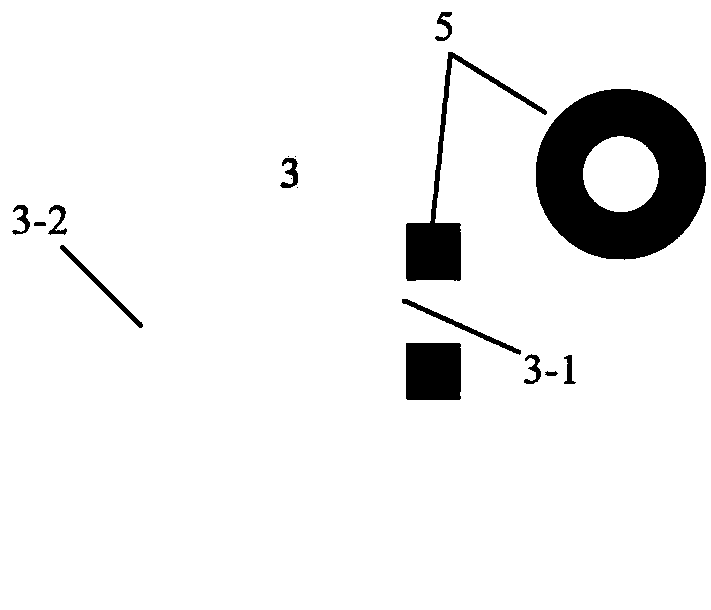

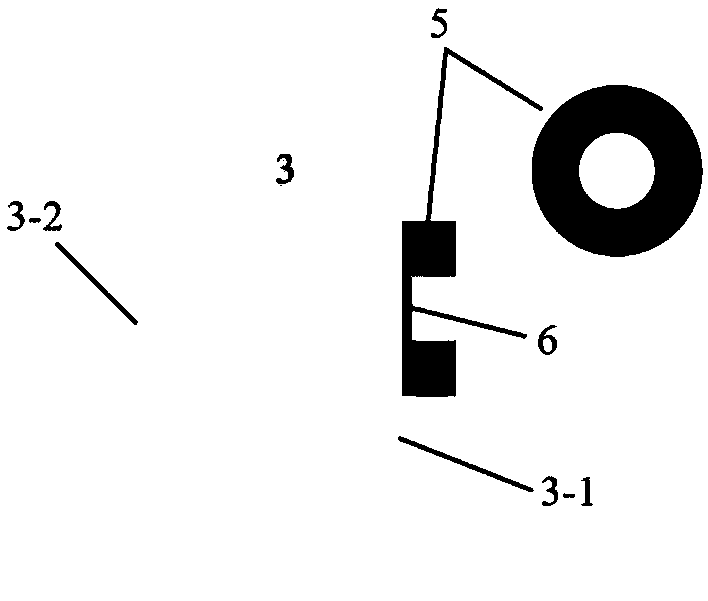

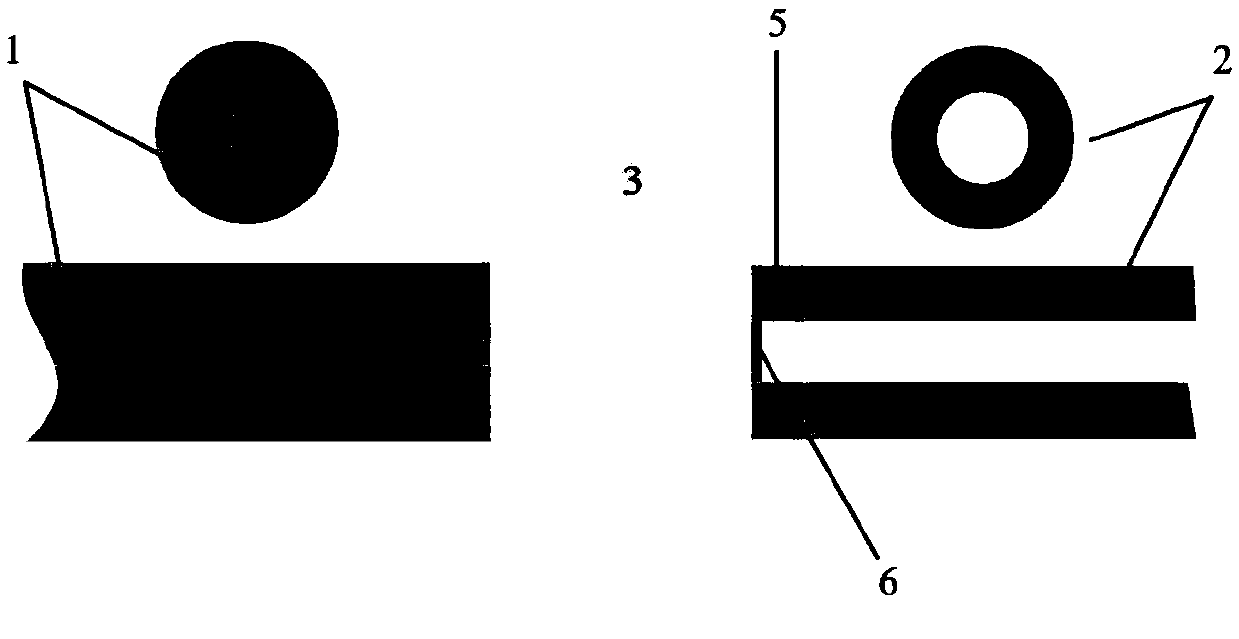

[0039] Example 1: Please refer to Figure 4 , Figure 4 It is a schematic diagram of the fusion splicing of a double-clad solid-core fiber and a nodeless anti-resonant hollow-core fiber: fiber 1 at the laser input end is a double-clad fiber, fiber 2 at the laser output end is a node-free anti-resonant hollow-core fiber, and the transition ring 5 is quartz ring.

[0040] 1) Obtain a double-clad fiber with a core diameter of 30 μm to be fused and a nodeless anti-resonant hollow fiber with a core diameter of 70 μm and a bare fiber diameter of 260 μm, strip the coating layer of the two, and then use a fiber cutter Cutting to ensure the smoothness and cleanliness of the fiber end face.

[0041] 2) The double-clad fiber is fused with the laser input end face 3-2 of the fiber end cap 3, so that the high-power laser beam in the core of the double-clad fiber is expanded 4, and the beam output diameter is diffused from about 30 μm to 60 μm -65μm, reduce the laser power density, and i...

Embodiment 2

[0045] Example 2: Please refer to Figure 5 , Figure 5 Schematic diagram of fusion splicing of double-clad solid-core fiber and ice-cream anti-resonance hollow-core fiber: fiber 1 at the laser input end is double-clad fiber, fiber 2 at the laser output end is ice-cream anti-resonance hollow-core fiber, and transition ring 5 is quartz ring.

[0046] 1) Obtain the double-clad optical fiber with a core diameter of 10 μm and the ice-cream anti-resonant hollow-core optical fiber with a core diameter of 36 μm and a bare fiber diameter of 130 μm to be fused, strip the coating layer of the two, and then use a fiber cutter Cutting to ensure the smoothness and cleanliness of the fiber end face.

[0047] 2) The output end face of the double-clad fiber is fused with the fiber end cap 3 to expand the high-power laser beam in the core of the double-clad fiber. As shown in 4, the output diameter of the beam is diffused from about 10 μm to 30 μm Left and right, the laser power density is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com