Air bag type intermediate supporting device for transmission shaft of commercial vehicle, assembling method and using method

A technology of intermediate support and transmission shaft, which is applied in control devices, vehicle components, transportation and packaging, etc., can solve the problems that the natural vibration frequency cannot be changed, affect the driving comfort of the whole vehicle, and affect the service life of bearings, etc., and achieve a simple assembly process. Convenience, excellent buffer performance, and the effect of solving heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

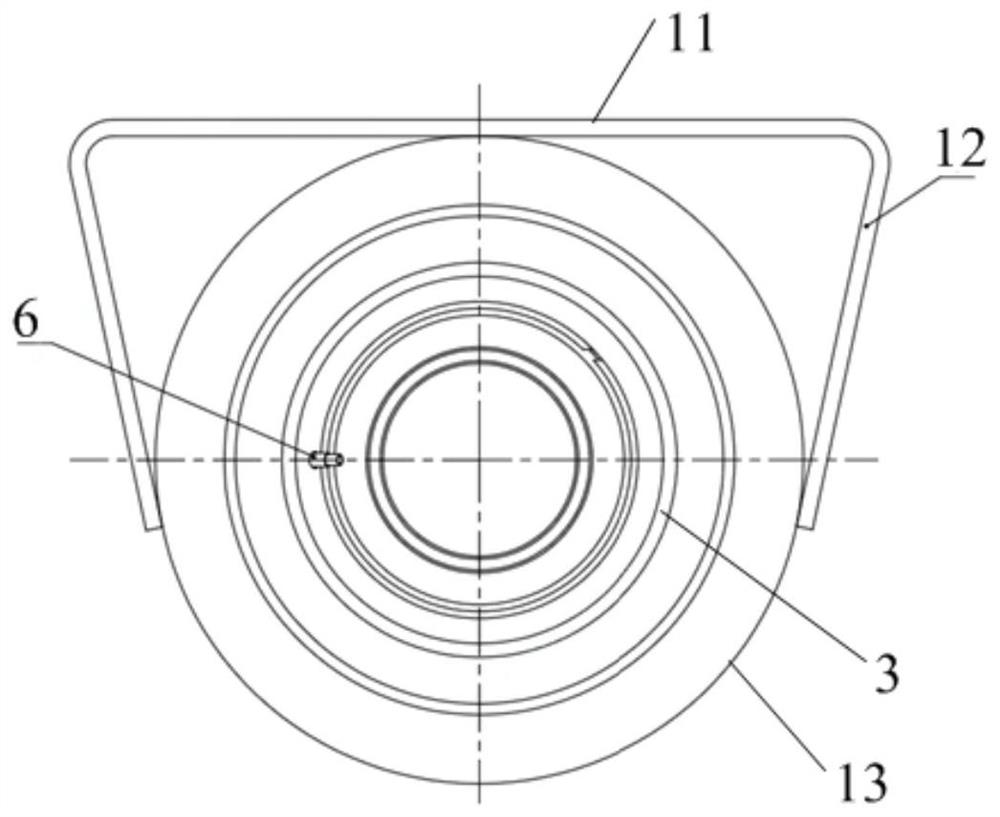

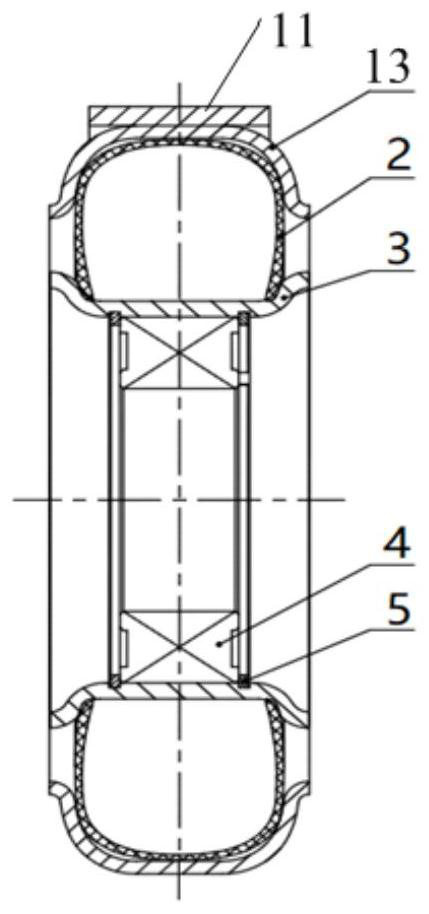

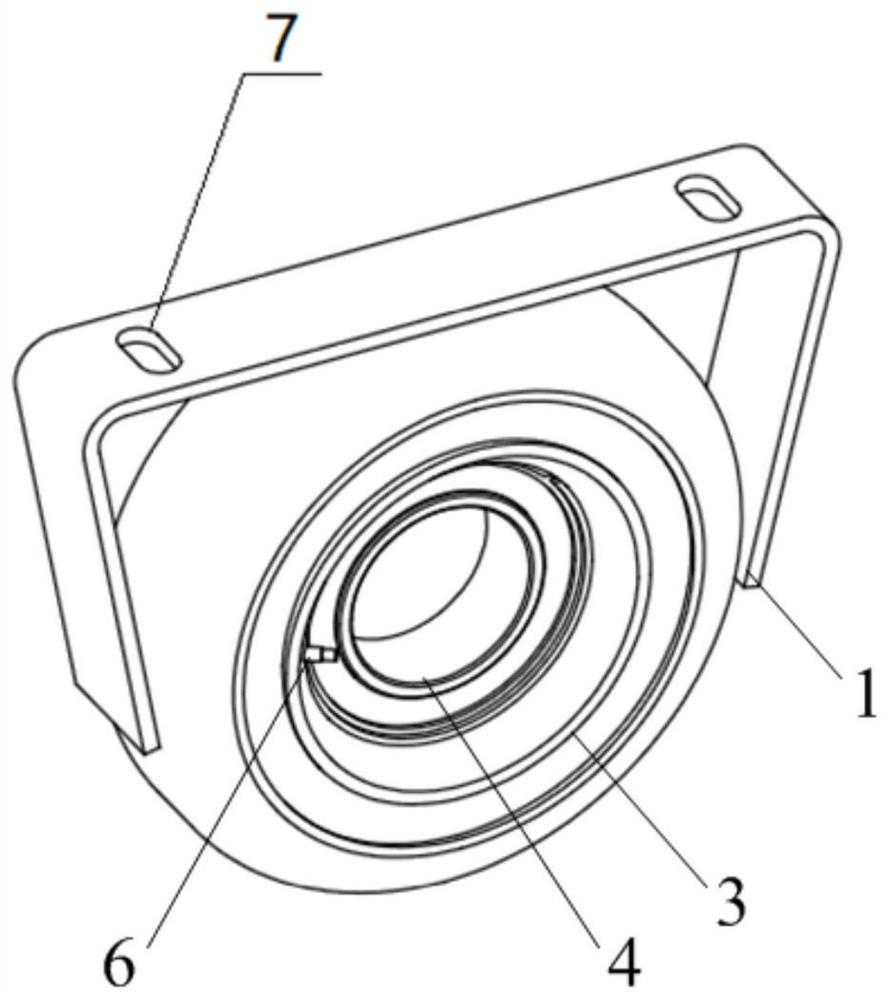

[0044] The invention provides an airbag-type intermediate support device for a commercial vehicle transmission shaft, such as Figures 1 to 3 As shown, including: rim type bearing housing 3;

[0045] The rim type bearing housing 3 is provided with an inner ring and an outer ring connected to each other; the outer periphery of the inner ring is press-fitted with a bearing 4; a slot is provided between the outer edge of the inner ring and the outer ring; a circlip 5 is installed in the slot, The circlip 5 is used to axially fix the bearing 4; the outer ring is equipped with an annular airbag 2; the inner surface of the annular airbag 2 is in contact with the outer annular surface, and the outer surface of the annular airbag 2 is connected with an annular composite bracket 1 ; The ring-shaped combined bracket 1 is connected with the vehicle frame.

[0046] It will be understood that when an element or layer is referred to as being "on," "connected" or "coupled" to another elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com