Disk spring

A disc spring and reed technology, applied in the field of springs, can solve the problems of insufficient damping ratio and complex structure, and achieve the effects of simplifying the structure, eliminating resonance and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

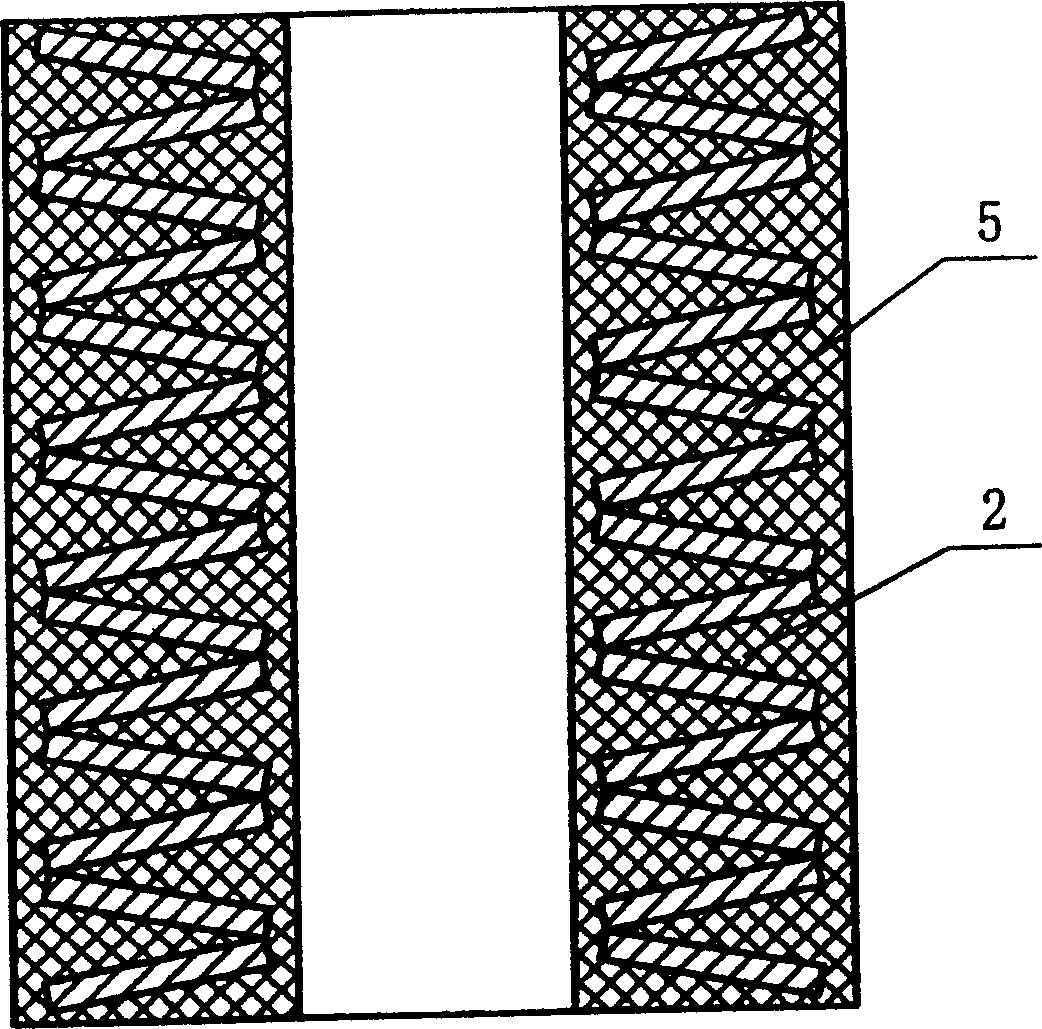

[0016] see figure 1 The disc spring group 5 composed of multiple disc springs is all embedded in the tubular damping body 2. When the coiled spring deforms, it will shear and squeeze the damping body 2. Since the damping body 2 is hollow, it is easy to deform.

[0017] The damping body is high damping modified asphalt which is solid (viscoplastic) at room temperature. When the disc spring is deformed by force, the damping body is deformed by force at the same time. Since the damping material has a large internal friction, it will always produce a damping force that is always opposite to the direction of motion. Therefore, the spring with this structure has a large damping ratio.

Embodiment 2

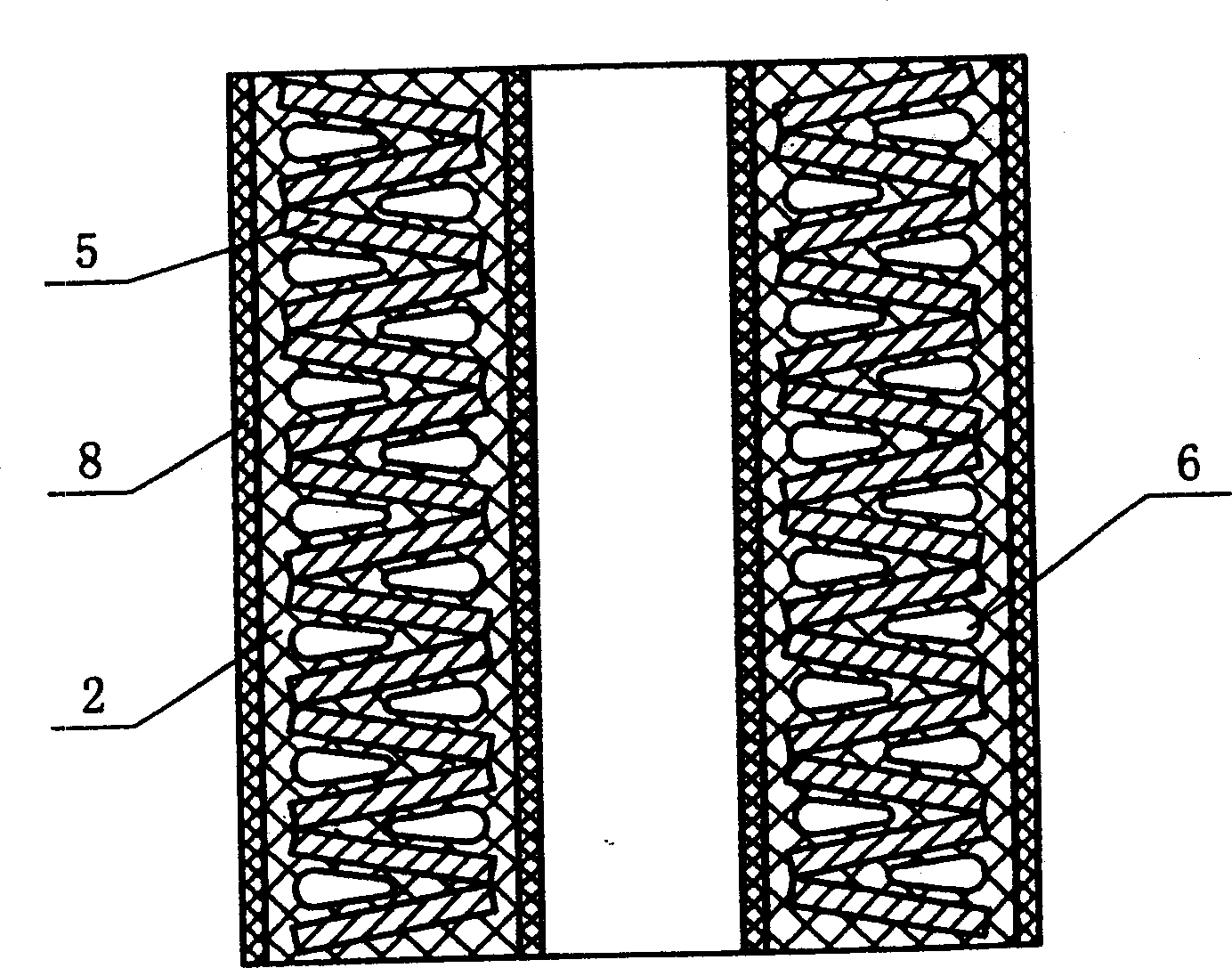

[0019] see figure 2 , the disc spring group 5 composed of a plurality of disc springs is integrally embedded in the tubular damping body 2, and there is an annular cavity 6 between the reeds, so the damping body is more susceptible to shear deformation and has a more Good linear stiffness and damping ratio. There is also a layer of elastic material on the inner and outer surfaces of the damping body as a restraint protection layer 8, which can help the damping material reset more completely when unloaded, and protect the damping material from the friction of the guide column and the impact of external force.

Embodiment 3

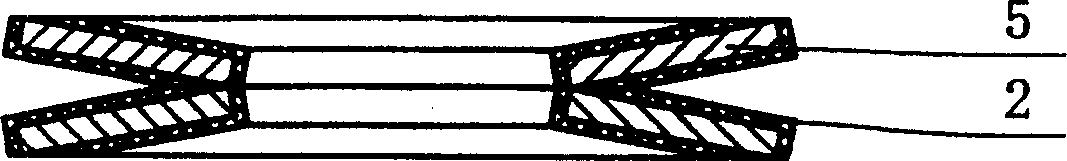

[0021] image 3 As shown, the disc spring 5 is single-piece embedded in the hollow damping body 2, and its cross-sectional shape is roughly concentrically similar to that of the reed, except that there is no damping body in the contact area of the disc spring to prevent the damping body from being partially squeezed Destruction or extrusion permanent deformation. This embodiment does not greatly change the linearity of the spring, and is suitable for occasions where the damping requirement is not too high but the linearity requirement is high. Due to the implementation of a single piece, it can be mass-produced. The damping body should be suitable for high-efficiency and mass production, such as damping materials that can be sprayed, dipped, coated or poured, such as high-damping polyurethane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com