Water-absorbent resin plastic concrete and preparation method thereof

A plastic concrete and water absorption technology, which is applied in the field of hydraulic engineering, can solve the problems of smaller volume, reduced concrete seepage resistance, and concrete has no seepage resistance, and achieves the effect of improving the seepage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

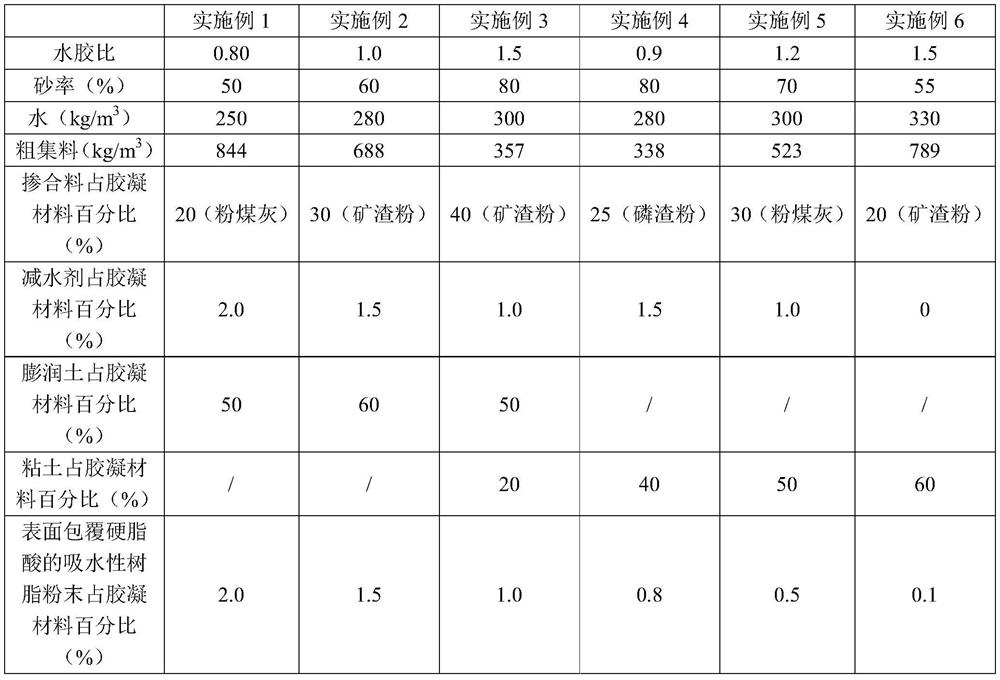

[0042] The preparation method of the water-absorbing resin plastic concrete of Examples 1-6 comprises the following steps:

[0043] (1) Co-grinding the water-absorbent resin and stearic acid in proportion to obtain a water-absorbent resin powder whose surface is coated with stearic acid.

[0044] (2) Sand and gravel are screened and stacked according to particle size for later use.

[0045] (3) Dry mix the water-absorbent resin powder coated with stearic acid into the cement and mix evenly.

[0046] (4) Air-dry the clay, and sieve it into clay with a particle size not greater than 0.16mm.

[0047] (5) Add water to the coarse aggregate, sand, admixture, water reducer, bentonite and / or clay, water-absorbent resin powder coated with stearic acid and cement according to the proportion, and use a mixer or manually to mix and prepare into plastic concrete.

[0048] (6) Plastic concrete curing.

[0049] For comparison, Comparative Examples 1 to 7 are provided below.

[0050] Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap