Laser color mixing structure

A laser and color mixing technology, applied in optics, optical components, instruments, etc., can solve problems such as complex structure and narrow color gamut of color mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

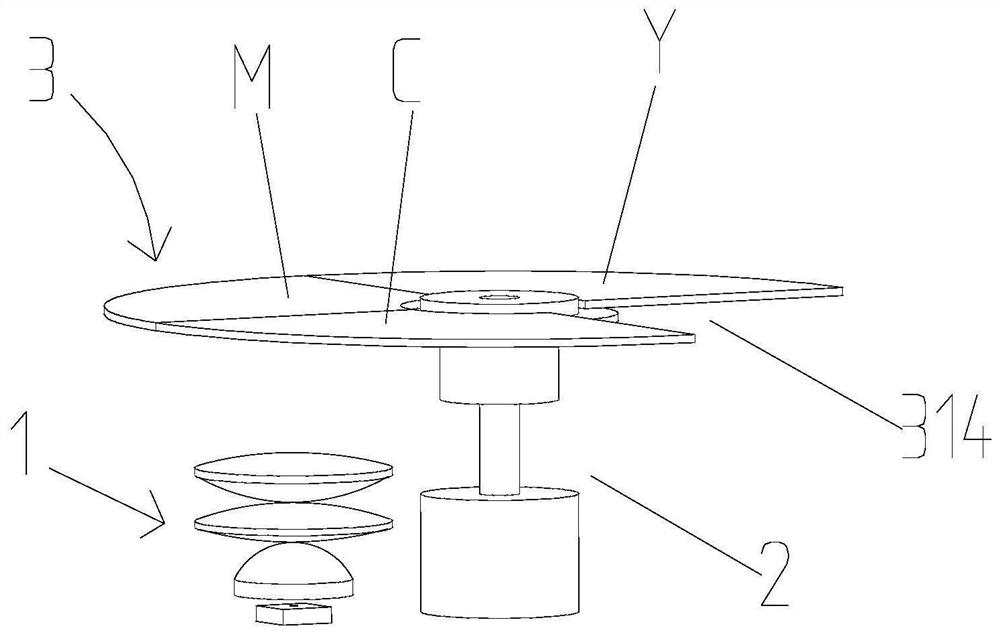

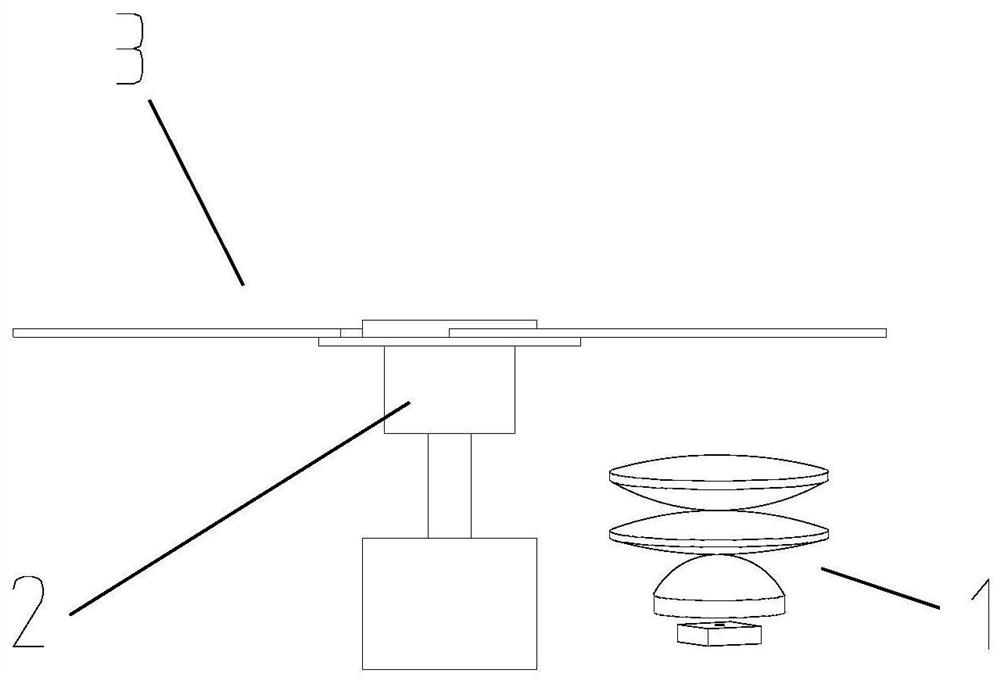

[0028] Figure 1 to Figure 3 The structure of the laser color mixing structure according to an embodiment of the present invention is schematically shown.

[0029] like Figure 1 to Figure 3 As shown in the figure, the laser color mixing structure includes a control system, a laser light source 1, a motor 2 and a color wheel piece 3; wherein, the laser light source 1 and the motor 2 are electrically connected to the control system respectively, and the motor 2 is set to drive the color wheel piece 3. Rotation; the color wheel 3 is provided with a plurality of color areas, and the plurality of color areas are arranged in a circular array around the rotation center axis of the color wheel 3; the plurality of color areas contain at least all basic colors of any color mixing mode; laser The light emitting direction of the light source 1 is aligned with the color area. In this embodiment, the laser light source 1 emits white laser light, and the rotating shaft of the motor 2 is c...

Embodiment 2

[0039] The difference between this embodiment and the first embodiment:

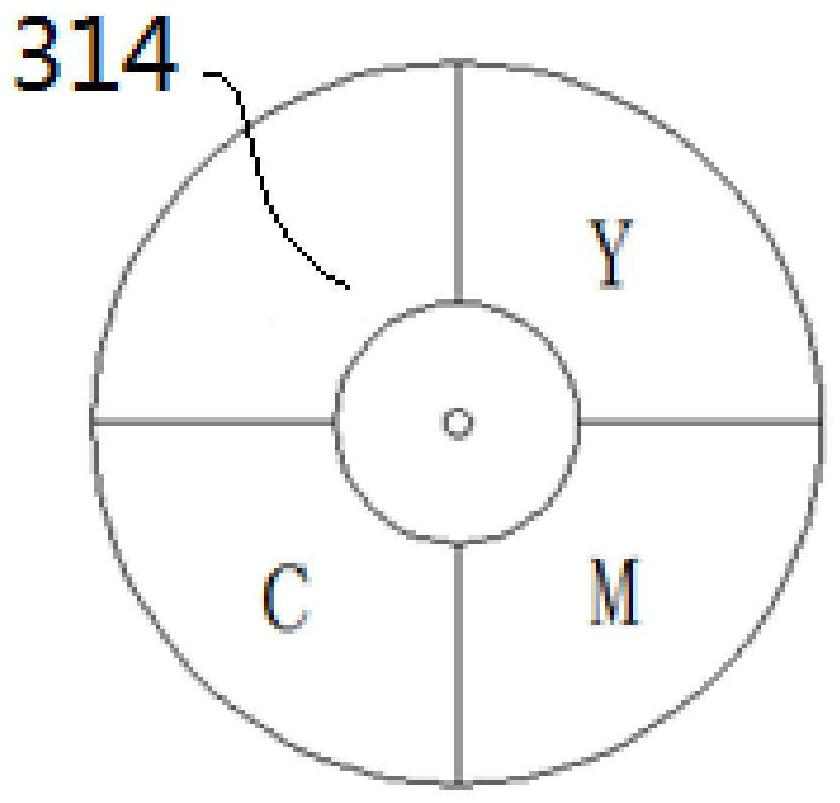

[0040] Figure 4 The structure of the laser color mixing structure of another embodiment of the present invention is schematically shown.

[0041] like Figure 4 As shown, in this embodiment, n color mixing function chip groups are arranged on the color wheel 3; the plurality of color areas also include n blank areas 314, and the blank areas 314 are separated between two adjacent color mixing function chips between groups; where n is a natural number greater than 0. and n≥2. Specifically, in this embodiment, n=2. In this way, by arranging a plurality of color mixing function film groups on the color wheel piece 3, within one rotation period of the color wheel piece 3, a higher cyclic switching frequency is obtained between the basic colors of the mixed color light, which is not easy to distinguish , so as to obtain better color mixing effect. At the same time, the laser light source 1 can also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com