Warp knitting workshop dust removal equipment

A dust removal equipment and workshop technology, applied in the direction of dust removal, dispersing particle filtration, combined devices, etc., can solve the health hazards of operators, mechanical equipment failures, and affect product quality. It achieves good dust removal effect, low cost, and improved air flow Radiation range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

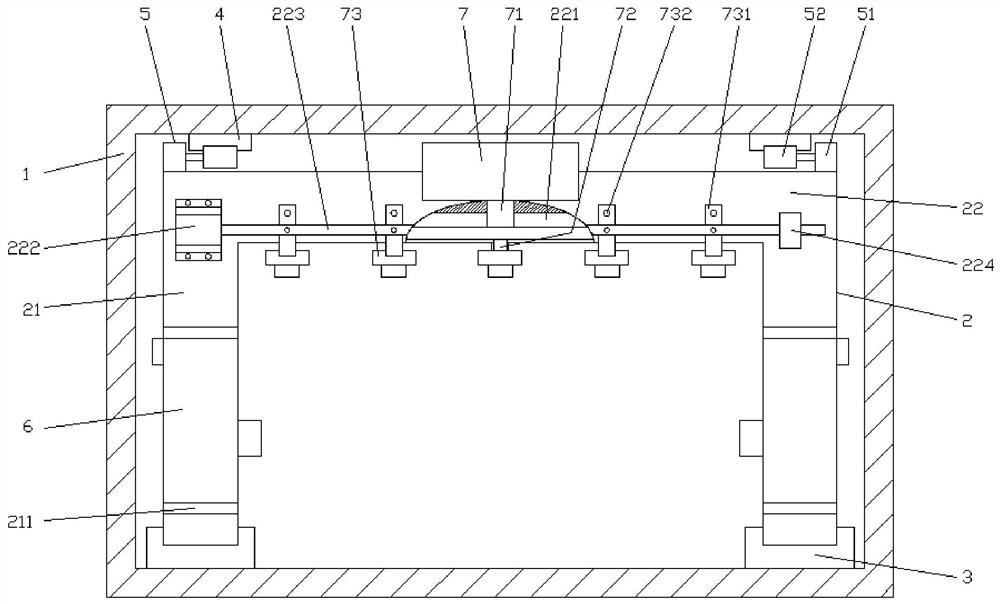

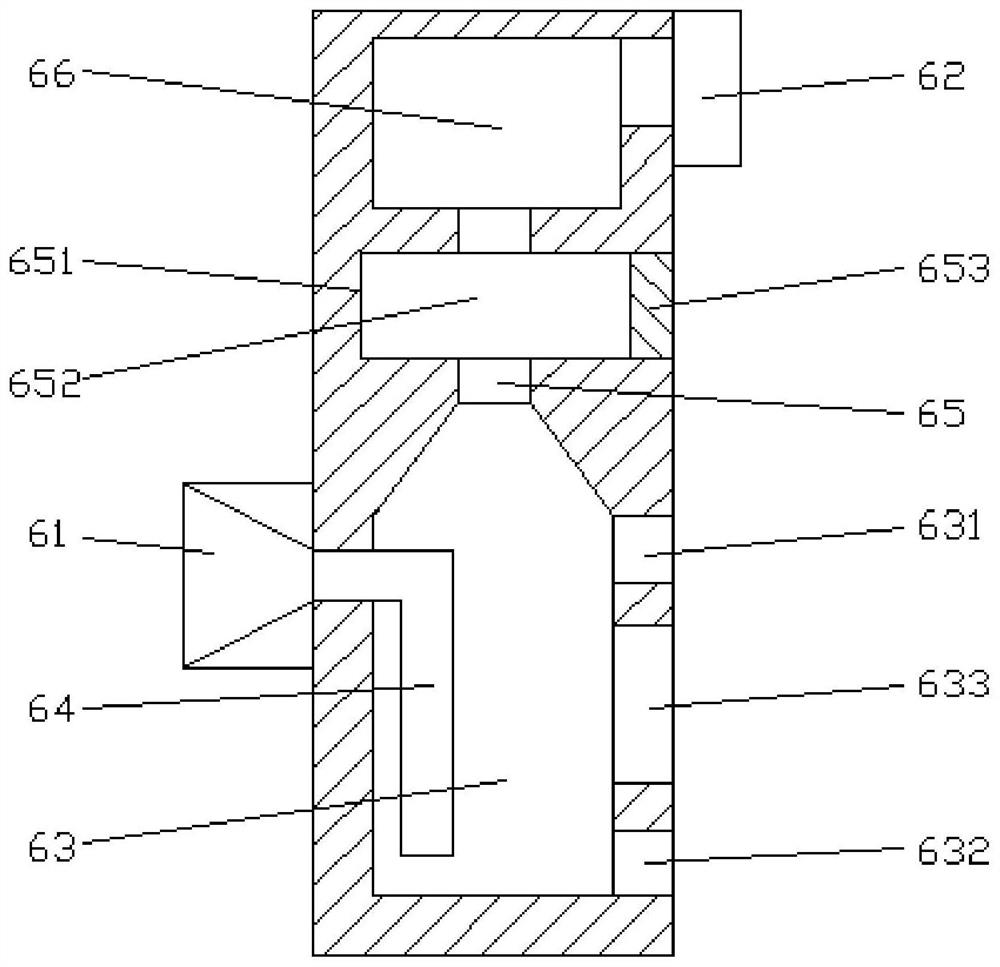

[0016] Referring to the accompanying drawings, the present invention is a warp knitting workshop dust removal equipment, including a workshop main body 1, characterized in that it also includes a movable support 2, a first slide rail 3, a second slide rail 4, a driving mechanism 5, a dust remover 6 and a blower Air machine 7, the interior of the main body 1 of the workshop is provided with a movable support 2, the movable support 2 is composed of a group of left and right symmetrical uprights 21 and crossbeams 22 between the uprights 21, the crossbeam 22 is located at the top of the uprights 21, the The bottom of the column 21 is provided with a first slide rail 3, the top of the cross beam 22 is provided with a second slide rail 4, and the two ends of the top surface of the cross beam 22 are provided with a drive mechanism 5, and the drive mechanism 5 also includes a drive motor 51 And driving wheel 52, the output shaft of described driving motor 51 is arranged oppositely, is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com