Pre-screwing device

A pre-screwing and mounting frame technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of low assembly efficiency and high labor cost, and achieve the effect of compact structure, strong versatility and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

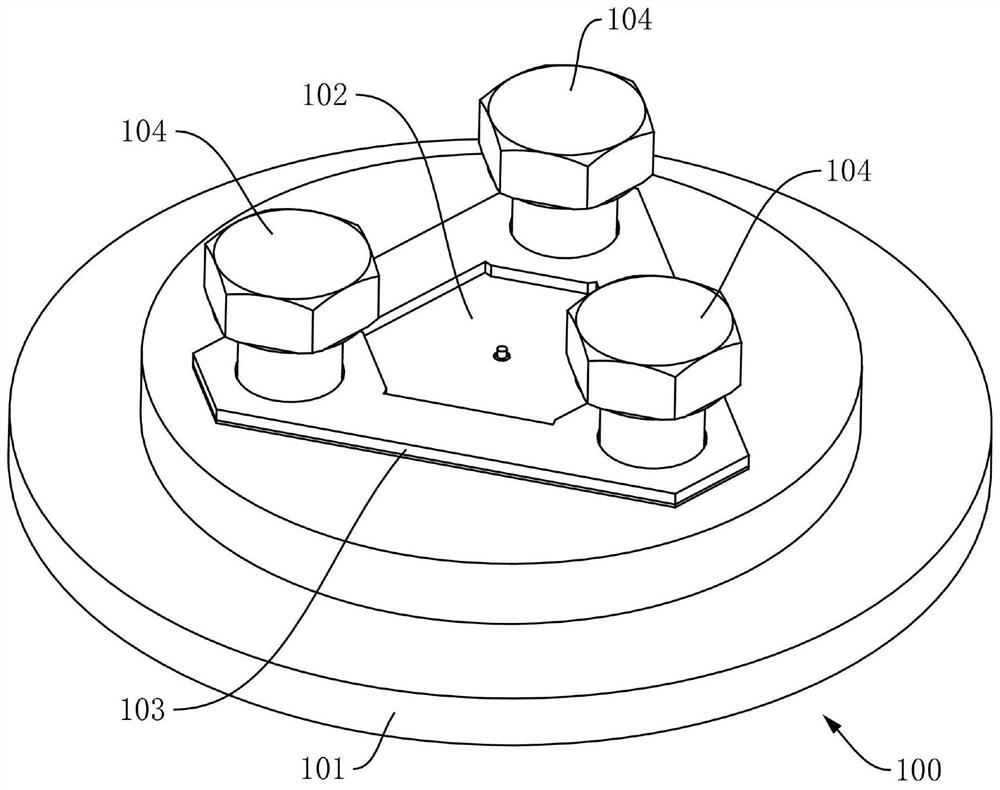

[0052] Such as Figure 2-Figure 16 As shown, this embodiment provides a pre-tightening device, including a mounting frame 300, a driving motor 501, and at least three rotating shafts 506, one end of which is provided with a torsion portion 508 adapted to the head of the bolt 104, The rotating shafts 506 are movably mounted on the mounting frame 300 through the bearing seats 400 respectively, and the rotating shafts 506 are respectively arranged uniformly along the circumferential direction of the same circle, and the positions of the bearing seats 400 can be adjusted along the radial direction of the circle respectively, so that Adapt to different types of front cover assemblies 100,

[0053] The drive motor 501 is used to drive the rotating shafts 506 to rotate so as to tighten the bolts.

[0054] In this embodiment, at least three rotating shafts are provided to match the number of bolts in the front cover assembly 100, and each rotating shaft 506 is evenly arranged along t...

Embodiment 2

[0077] In order to solve the force balance problem of each rotating shaft 506, the main difference between this embodiment 2 and the above-mentioned embodiment 1 is that in the pre-tightening device provided by this embodiment, the mounting frame 300 includes a first support body 308 and a second support body 308 support body 309, such as Figure 11 and Figure 12 As shown, the first support body 308 and the second support body 309 are connected through several support members 304, and there is a gap between the first support body 308 and the second support body 309, so as to install transmission components,

[0078] The first support body 308 and the second support body 309 are respectively provided with strip-shaped slots 302 with the same number and the same position, and the rotating shaft 506 is respectively connected to the first support body 308 and the second support body 309 through two bearing seats 400, Such as Figure 11 and Figure 12 As shown, and the first su...

Embodiment 3

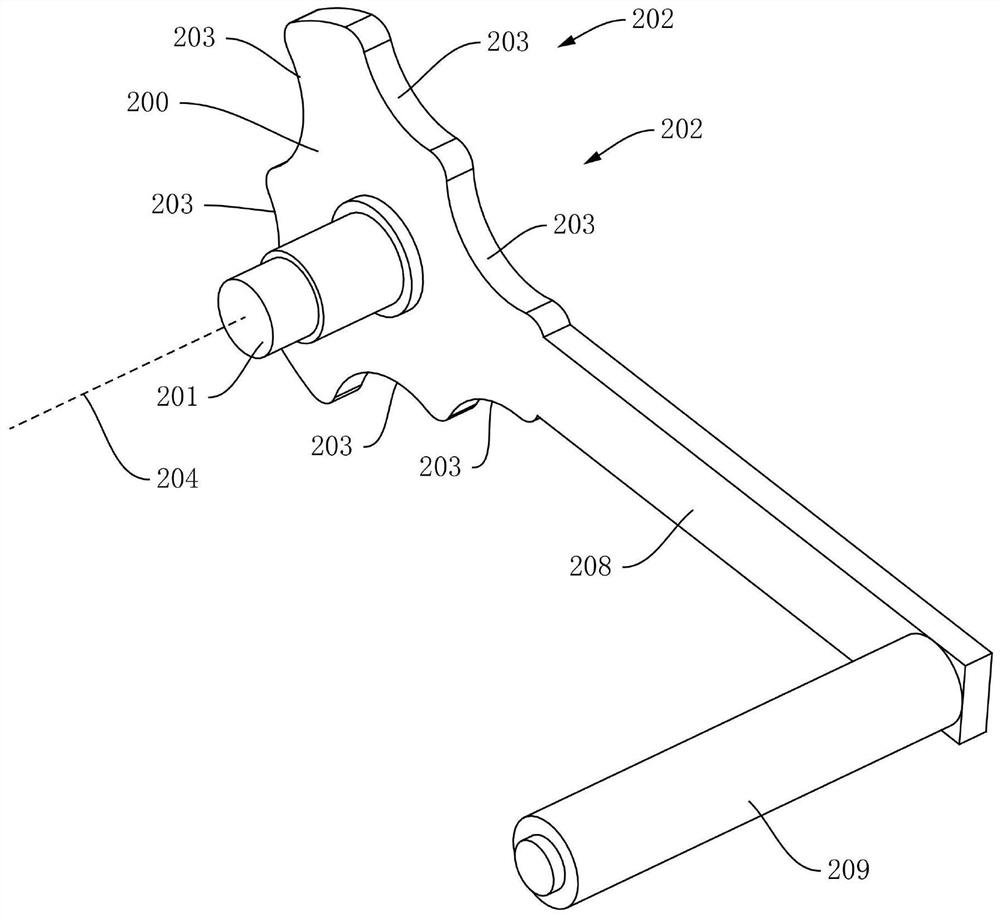

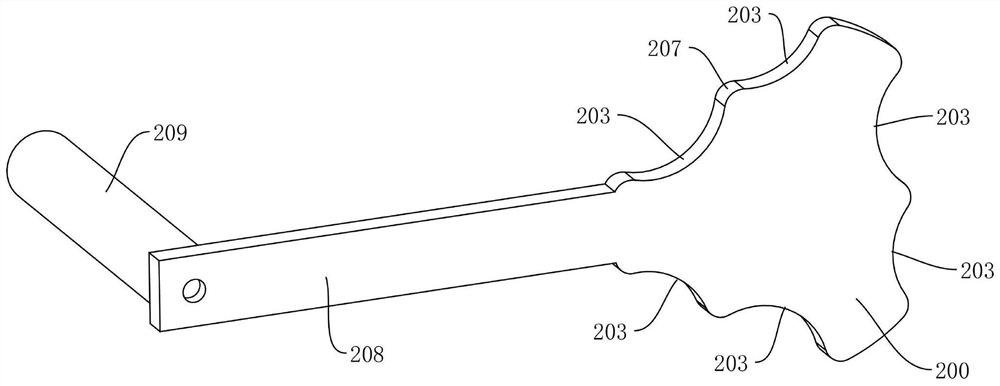

[0084] In order to solve the locking problem of the rotating shaft 506 or the bearing seat 400, the main difference between this embodiment 3 and the above-mentioned embodiment 2 or embodiment 1 is that the pre-tightening device provided by this embodiment also includes a number of springs 306. One end of the spring 306 is respectively connected with the bearing seat 400, and the other end is respectively connected with the support body 301. The spring 306 is used to provide the bearing seat 400 with an elastic force in the radial direction and directed to the central axis of the second mounting part 303, such as Figure 13 As shown, the setting of the spring 306 can provide the bearing seat 400 with an elastic force in the radial direction and directed to the central axis of the second mounting part 303, so that each bearing seat 400 or the rotating shaft 506 arranged on the bearing seat 400 can press the adjustment member 200 The limit groove 203, that is, the bearing seat 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com