Hot-pressing device for plywood production based on 5G technology

A hot-pressing device and technology for plywood, applied in the field of hot-pressing of plywood, can solve the problems of position deviation of the plywood, inability to fix the plywood, and poor plywood effect, and achieve the effect of improving adaptability, improving the scope of application and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

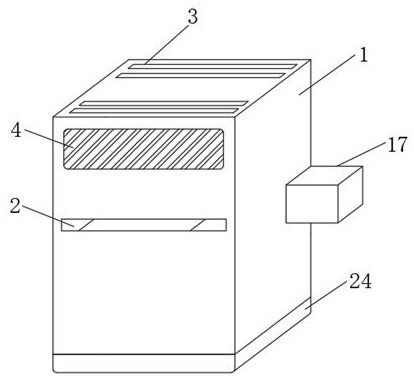

[0031] see Figure 1-6 , in an embodiment of the present invention, a plywood production hot-pressing device based on 5G technology includes a hot-press box 1, a heating plate 11 and a base 13, and a motor box 17 is fixedly connected to the outer side of the hot-press box 1, and the motor box 17 is provided with a motor 18 inside, the inner lower end of the autoclave 1 is fixedly connected with a support column 12, and the upper end of the support column 12 is fixedly connected with a base 13, which is convenient for placing the plywood on the base 13, and one side of the base 13 is provided with a limit rod 14, and the limit rod 14 is fixedly connected to the inner side of the autoclave 1, the inside of the limit rod 14 is provided with a chute 15, the inside of the chute 15 is provided with a positive and negative screw rod 16, a positive and negative screw rod 16 and a motor 18 is connected by transmission, and the end of the limit rod 14 away from the motor 18 is fixedly c...

Embodiment 2

[0040] During the implementation of the present invention, the applicant found that in the process of hot-pressing plywood, rotating the positive and negative threaded screw 16 drives the two stoppers 23 to move relative to each other through the slider 22, which can realize the limitation and fixation of plywood of different sizes. But in order to ensure that the plywood is formed by one-time hot pressing, the area of the heating plate 11 must not be less than the area of the plywood between the two movable stoppers 23, so the two stoppers 13 are generally located under the heating plate 11, and are produced during production. During the process, as the plywood is heated and pressurized, the plywood is gradually compressed, and the thickness gradually decreases. The buffer spring 10 pushes the heating plate 11 to move downward through the connecting rod, and continues to heat the plywood. The stopper 23 located under the heating plate 11 If the height is too large, the dow...

Embodiment 3

[0043] After the applicant further improved the device and implemented it, it was found that when the device was heat-bonding thick plywood, the thickness of some plywood could reach more than 10 cm, and the scheme in Example 2 was used to heat-bond this type of particularly thick plywood At this time, it is necessary for the hot pressing plate 11 to compress the compression spring 29 largely through the pressing block 28, and at the same time, the reaction force of the compressed spring 29 that is greatly compressed to the hot pressing plate 11 through the pressing block 28 is relatively large, and the larger reaction force will It affects the heat-sealing effect of the heat-pressing plate 11 on the heat-sealing plate below, resulting in insufficient heat-sealing pressure of the plywood, which affects product quality. Therefore, the present application makes a further improvement when aiming at the hot pressing of this type of thicker plywood.

[0044] Such as Figure 7-8 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com