Movable aircraft main wheel mounting equipment

An installation equipment and mobile technology, applied in the field of movable aircraft main wheel installation equipment, can solve problems such as backward operation methods, quality and safety problems, and difficulty, and achieve the effects of fewer operators, easy maintenance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

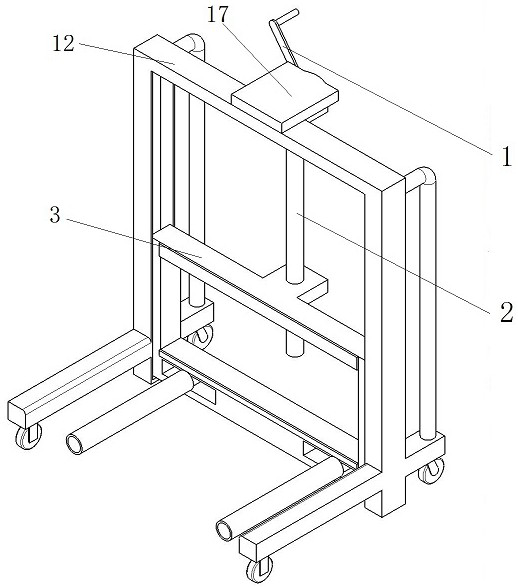

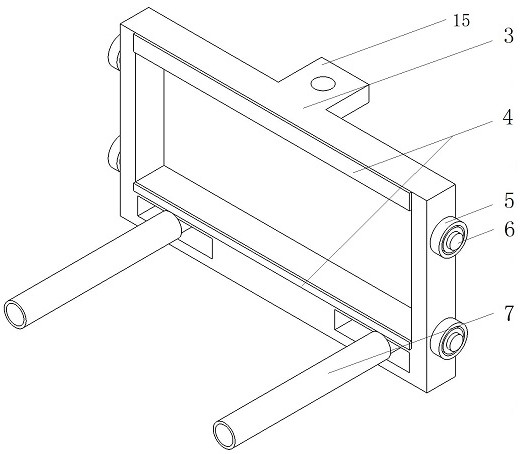

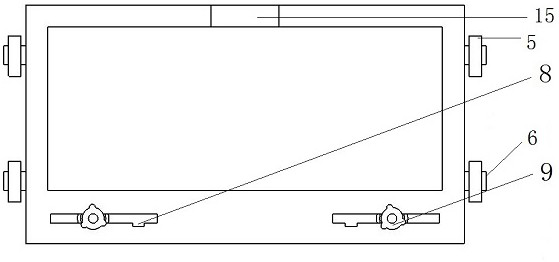

[0040] The present invention proposes a movable aircraft main wheel 20 installation device for installing the aircraft main wheel 20, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the installation equipment includes an outer support structure, an inner load-bearing structure installed on the outer support structure, a lifting structure connected with the outer support structure and the inner load-bearing structure; the main engine wheel 20 of the aircraft is carried on the inner load-bearing structure for Aircraft main wheel 20 is installed;

[0041] The inner load-bearing structure includes an inner main frame 3, a fork rod 7, a limit groove 8, a self-locking plate 9, a bearing 5, a connecting shaft 6, an inner connecting ear 15, and a rubber pad 4;

[0042] The outer support structure includes outer connecting ears 16, guide rails 10, outer main frame 12, moving rod 18, universal wheels 13, directional wheels 14, and handle 11;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com