Stacking machine

A stacker and rack technology, applied in the field of stackers that are easy to unload, can solve problems such as equipment and cargo damage, collision between forks and cargo platforms, economic losses, etc., to improve stacking efficiency and stacking. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

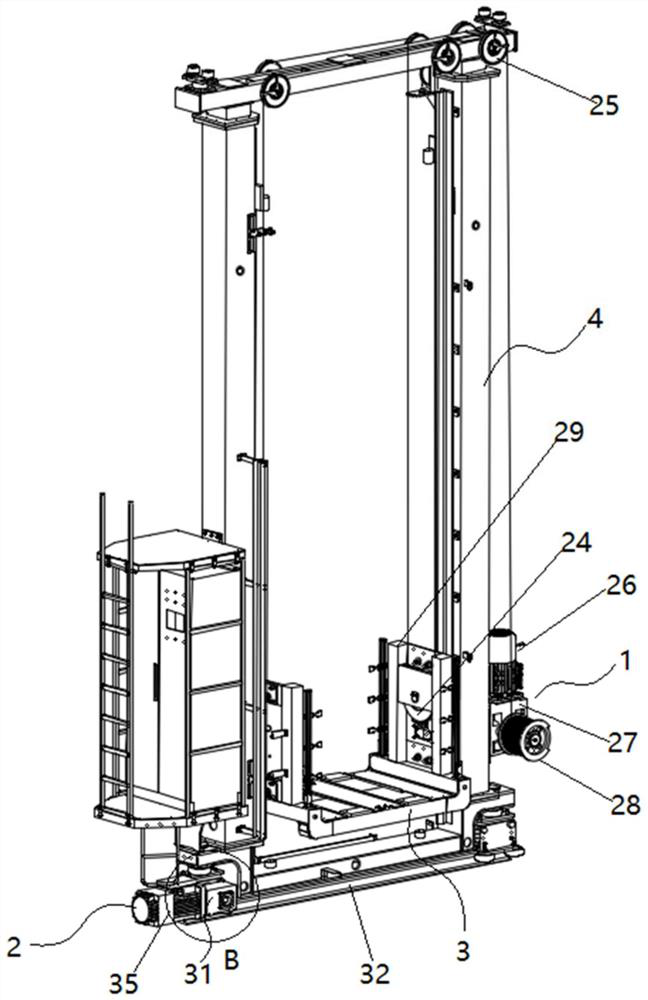

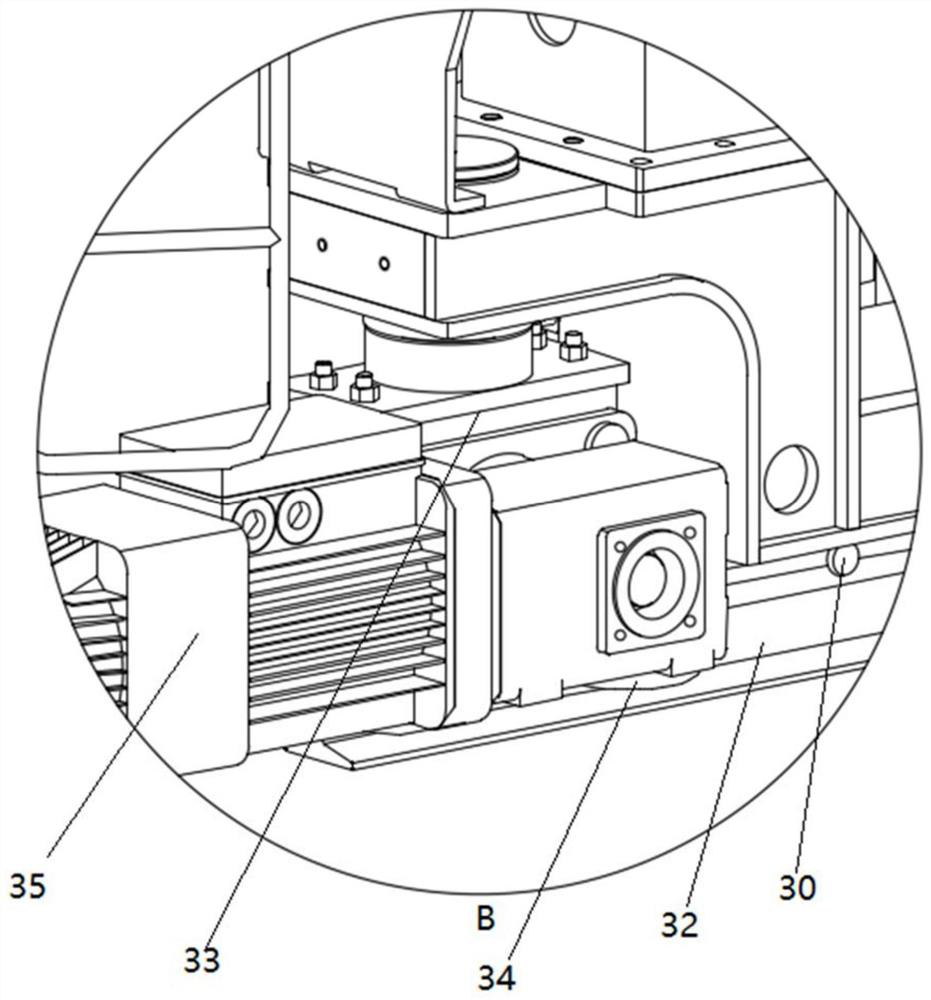

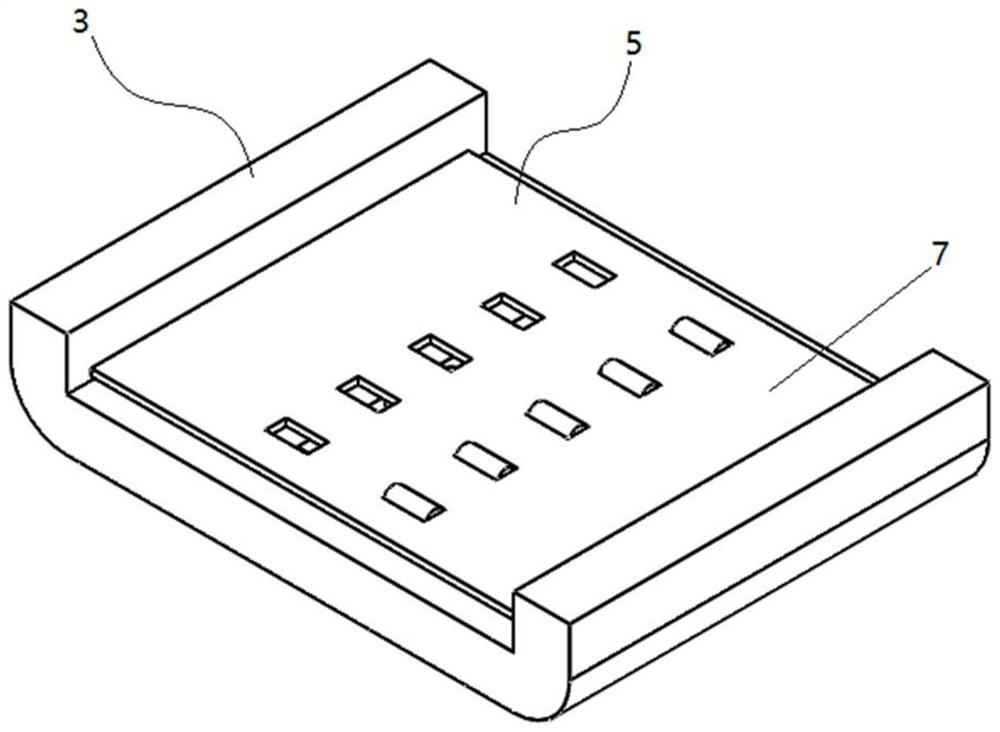

[0025] A stacker, including a lifting mechanism 1, a translation mechanism 2, a loading platform 3, a frame 4 and an unloading mechanism 5, the translation mechanism 2 is installed at the lower end of the frame 4, and the translation mechanism 2 drives the frame 4 to generate Translate, so that the items are placed in different positions. The loading platform 3 is slidably installed on the frame 4. The loading platform 3 is used to carry the items to be stacked. The lifting mechanism 1 is connected to the loading platform 3 to drive the loading The platform 3 is lifted and lowered to facilitate moving the items to be stacked to the corresponding height. The unloading mechanism 5 is slidably installed on the loading platform 3, that is, the items to be stacked are placed on the unloading mechanism 5, and the items to be stacked are unloaded by the unloading mechanism 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com