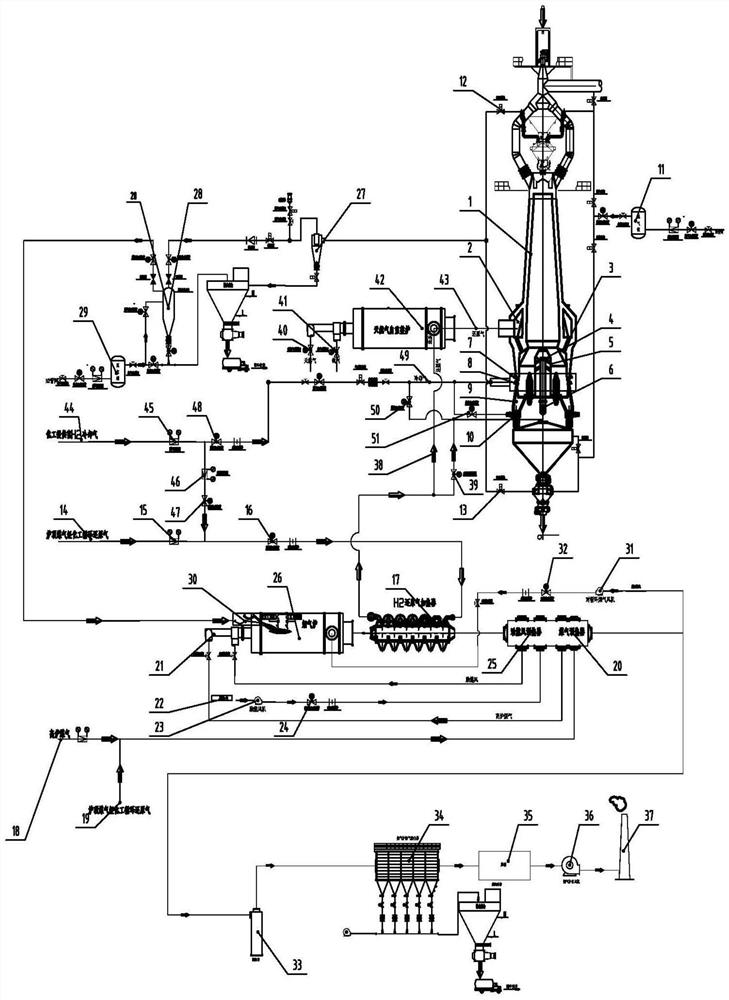

Hydrogen metallurgy shaft furnace system

A technology of hydrogen metallurgy and shaft furnace, applied in the field of hydrogen metallurgy shaft furnace system, which can solve the problems of high energy consumption and high metallurgical cost of shaft furnace, and achieve the effects of simple process, obvious energy saving effect and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

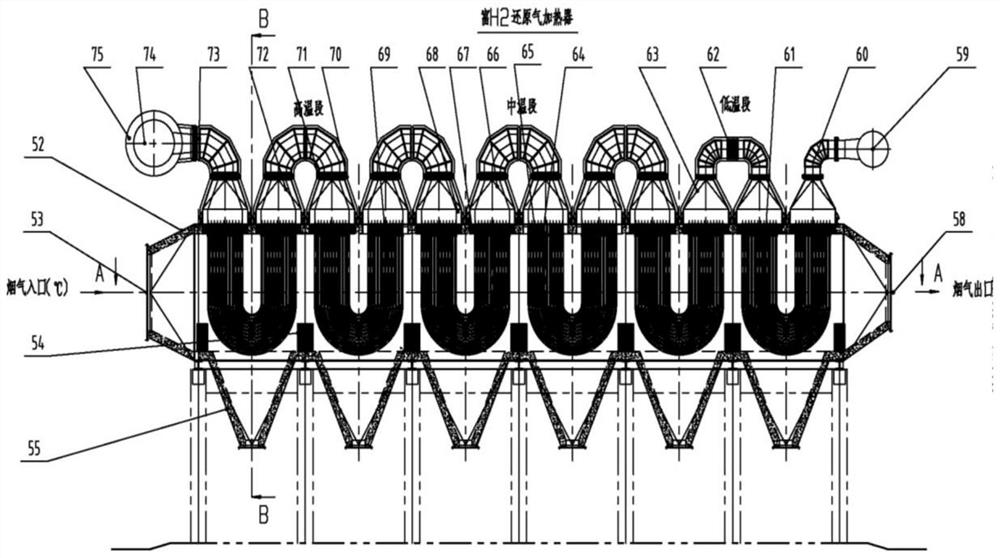

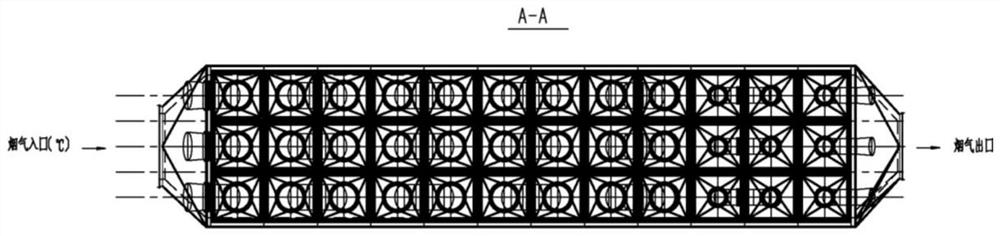

[0044] The invention provides a hydrogen metallurgy shaft furnace system, such as Figure 1 to Figure 8 As shown, it includes a hydrogen-rich reducing gas heating unit, the hydrogen-rich reducing gas heating unit includes a heater body, and the heater body (that is, the heater smoke chamber) includes a heater sub-box 52 and a smoke chamber disposed at both ends of the heater body. The gas inlet 53 and the flue gas outlet 58; the heater sub-box 52 is provided with a high temperature section heating tube bundle 69, a medium temperature section heating tube bundle 64 and a low temperature section heating tube bundle 61; the hydrogen-rich reducing gas 14 is successively passed through the low temperature section heating tube bundle 61. The middle temperature section heating tube bundle 64 and the high temperature section heating tube bundle 69 realize reverse heat exchange with the flue gas in the heater sub-box 52 .

[0045] Specifically, the heater body provided by the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com