Reinforced hot melt pile/reinforced gravel pile composite roadbed structure in degenerated permafrost region

A technology of composite subgrade and permafrost foundation, which is applied in the direction of infrastructure engineering, roads, roads, etc., can solve the problems of road thawing damage, insufficient bearing capacity of the foundation, and ineffective control, so as to reduce subgrade settlement, improve bearing capacity, The effect of increasing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

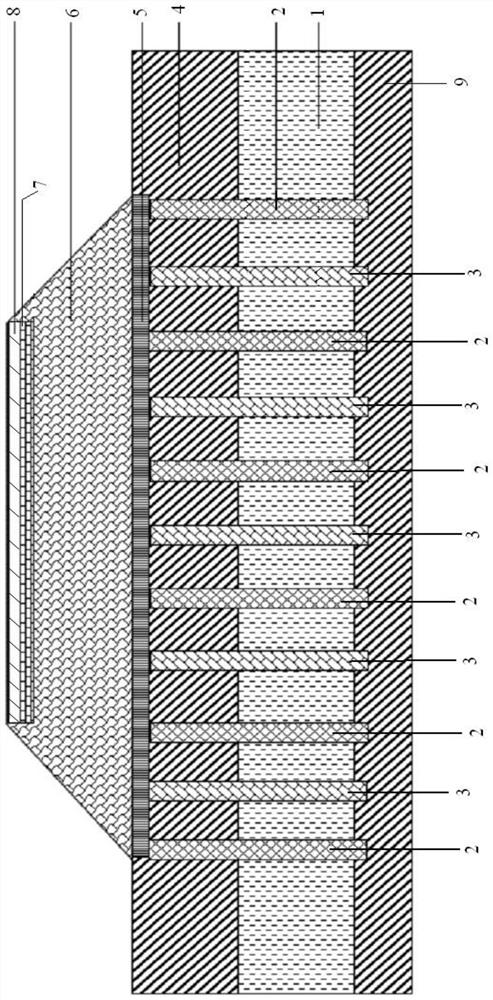

[0021] Specific implementation mode 1: This implementation mode is a composite subgrade structure of reinforced heat-thaw piles / reinforced crushed stone piles in degraded permafrost areas, such as Figure 1-Figure 7 As shown, it is specifically composed of permafrost foundation 1, reinforced thermal melting pile 2, reinforced gravel pile 3, upper unfrozen foundation 4, drainage sand cushion 5, embankment 6, pavement base layer 7, pavement surface layer 8 It is composed of the unfrozen ground foundation 9 in the lower layer;

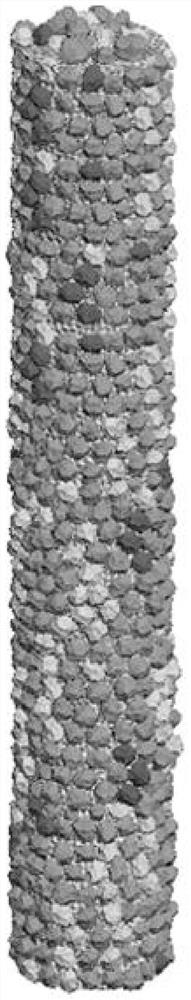

[0022] The reinforced hot-melt pile 2 is composed of gravel soil, quicklime, cement and geogrid; quicklime, cement and water are mixed and then cemented with gravel soil to form a pile body, and the geogrid encloses a hollow structure Wrapped around the pile body to form a reinforced heat-melt pile 2, combined with the lateral restraint provided by the geogrid, it has good strength and rigidity; the quicklime component in the reinforced heat-melt pile 2 c...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that sensors are arranged around the reinforced heat-melt pile 2 to monitor changes in temperature, humidity, displacement and pore water pressure. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the geogrid in the reinforced heat-melt pile 2 is a steel-plastic geogrid. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com