Double-section high-strength bolt anti-loosening connecting joint for space grid structure and construction and installation method thereof

A technology of high-strength bolts and space grids, which is applied in the direction of building construction and construction, can solve the problems of inability to visually judge high-strength bolts, high-strength bolts cannot be tightened, and are hidden in sleeves, so as to save installation procedures and time, Ease of project supervision and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

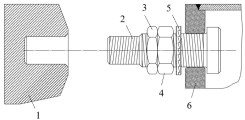

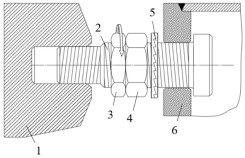

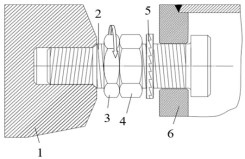

[0018] Figure 1 ~ Figure 5 It is a schematic diagram of the installation steps of the node at the project site. As shown in the figure, the node includes the node body 1, the double-section high-strength bolt 2, the inner nut 3, the outer nut 4, the lock washer 5, and the rod end connector 6. This implementation In the manner, the rod end connecting piece 6 is a sealing plate, and the sealing plate and the rod are welded.

[0019] Construction and installation method:

[0020] (1) First, process the components of the node and the members of the spatial grid structure in the factory according to the design and processing drawings;

[0021] (2) Factory assembly: Pass the screw of the double-section high-strength bolt 2 through the corresponding round hole of the sealing plate 6 from the rod connection side, and then pass through the round hole of the lock washer 5, of which two pieces of the lock washer 5 have large teeth Face each other, and then screw the inner nut 3 and the outer n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com