Tunnel blind pipe reaming machine and using method thereof

A technology of reaming machine and blind pipe, which is applied in the field of reaming machine, can solve the problems of debris congestion in the scupper hole, affecting drainage, and long service time, and achieves a good support effect, ensures normal use, and is convenient and fast for reaming. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific structure of the tunnel blind pipe reaming machine of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

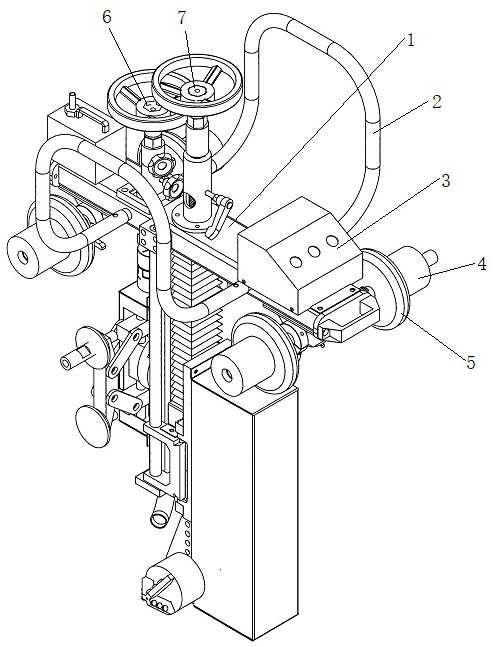

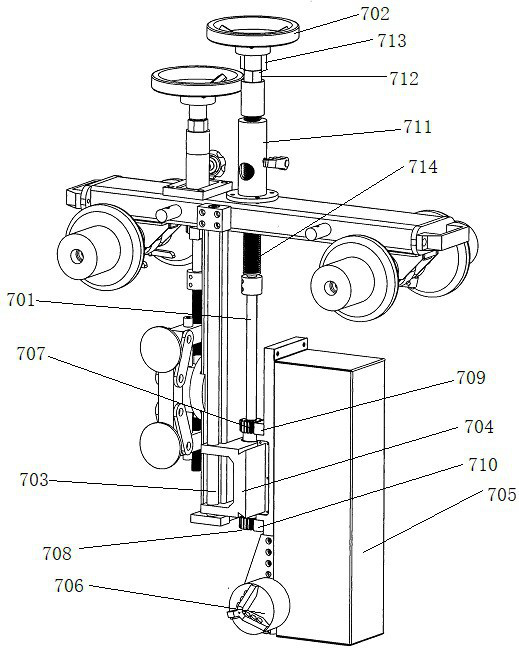

[0028] Such as figure 1 As shown, the tunnel blind pipe reaming machine of the present invention includes a frame 1, the upper part of the frame 1 is provided with a handrail 2 and a motor 3, the lower part of the frame 1 is provided with a roller 4, and the side of the roller 4 close to the frame 1 is provided with a limit plate 5. The frame 1 is provided with a support device 6 and a drilling device 7 .

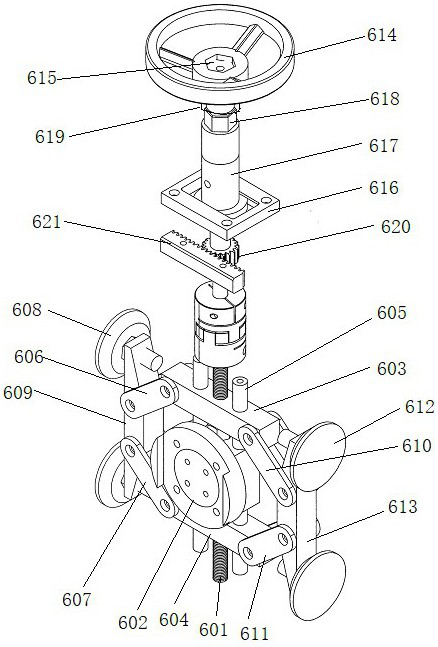

[0029] Such as figure 2 As shown, the support device 6 includes a support box 602 with a support screw 601, an upper strut 603 that matches the support screw 601 is arranged above the support box 602, and an upper strut 603 that matches the support screw 601 is arranged below the support box 602. The lower strut 604, the thread of the support screw 601 at the upper str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com