Linear output ventilator control method based on movable blade and rotating speed coupling adjustment

A speed coupling and control method technology, applied in the direction of pump control, machine/engine, mechanical equipment, etc., can solve the problems of wind pressure increase, decrease, and adverse effects on combustion stability in the furnace, so as to eliminate jumps, improve adjustment accuracy, The best overall performance of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

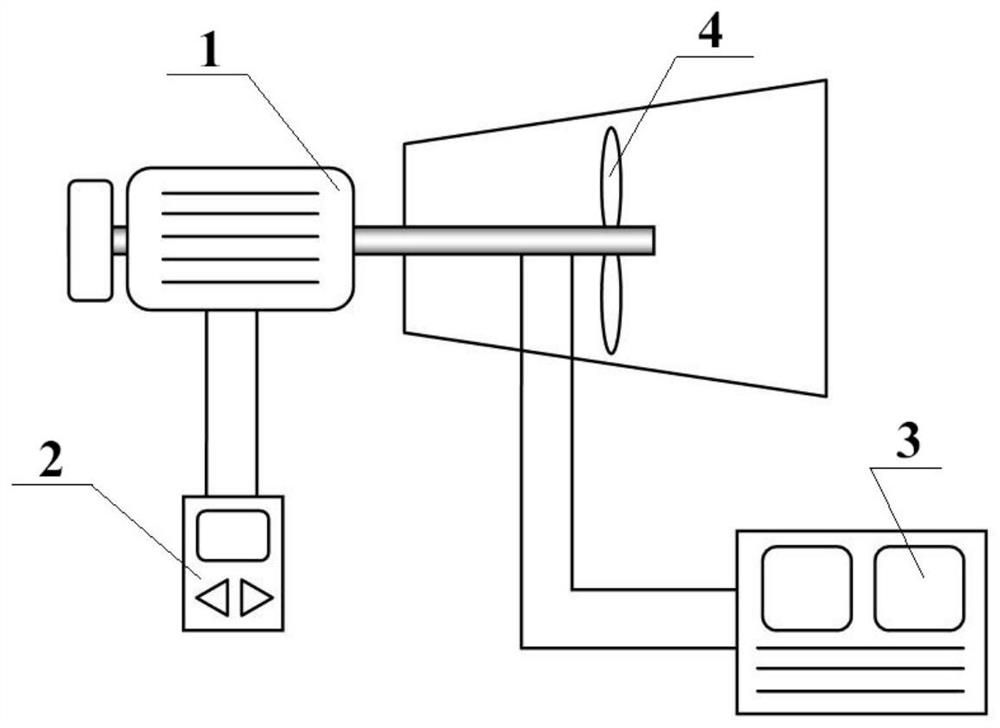

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

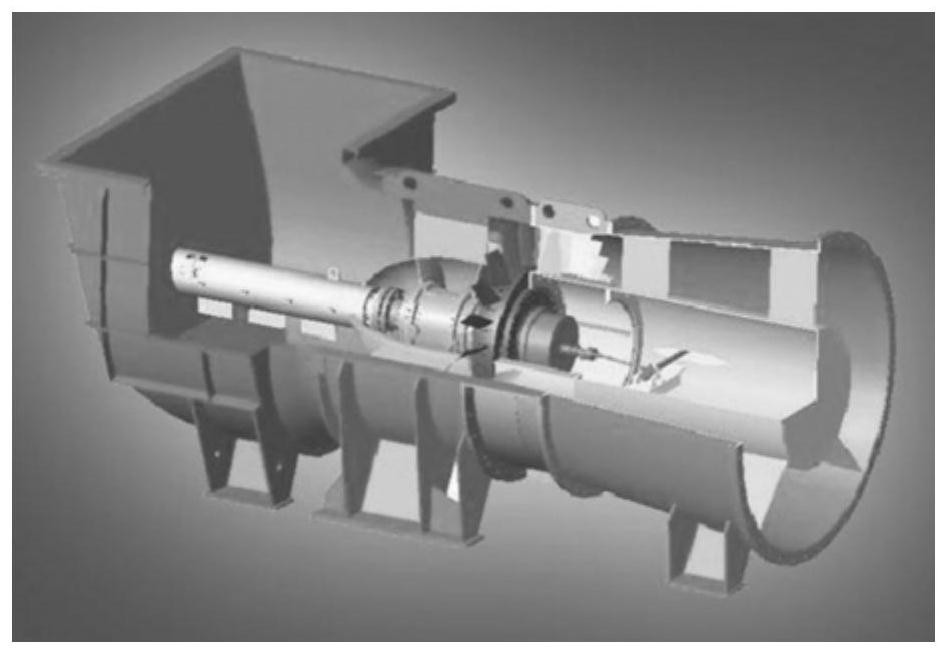

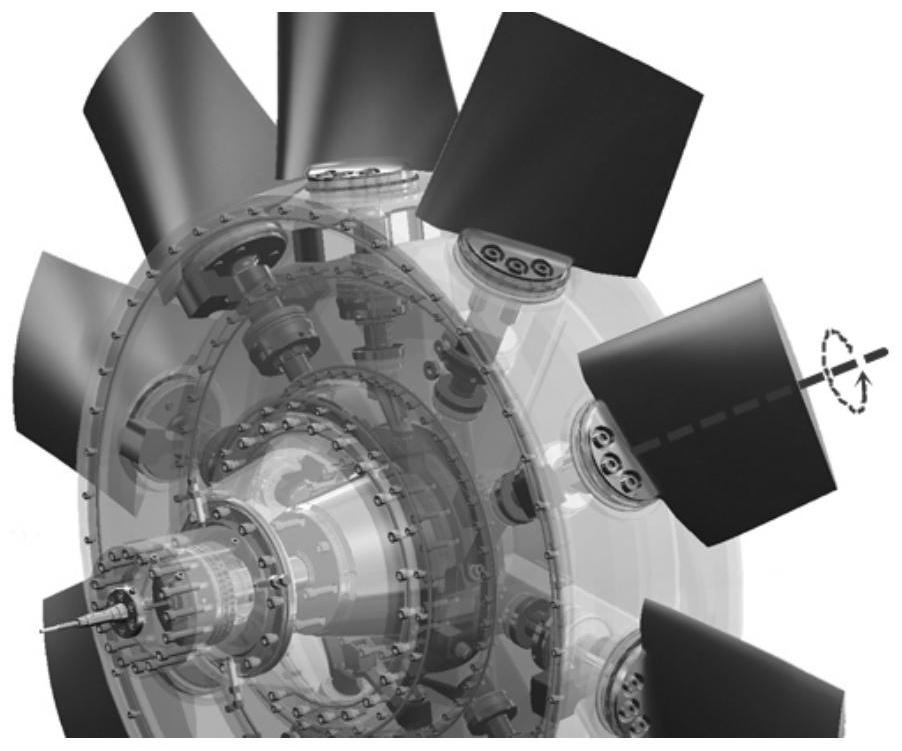

[0024] refer to image 3 According to the present invention, the linear output fan control method based on the rotor speed coupling adjustment includes the following steps:

[0025] 1) Select several typical working condition points, and obtain the parameters of each typical working condition point through experiments, wherein, the parameters of the typical working condition points include the current value of the motor 1, the fan speed and the angle of the moving blade 4, and establish the current value of the motor 1 The corresponding relationship between the value and the fan speed and the angle of the moving blade 4;

[0026] At a certain working condition point, the determined current value I of the motor 1 has a corresponding relationship with the fan speed P and the angle D of the moving blade 4. Therefore, the typical working condition point X can be used as I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com