Following-type hydraulic damping device, system and method

A hydraulic vibration damping and hydraulic cylinder technology, applied in springs/shock absorbers, vibration suppression adjustment, supporting machines, etc., can solve problems such as difficulty in meeting the test requirements of diesel engine manufacturers, distance of natural vibration frequencies, and inability to orientately adjust up and down. Simplify the installation and debugging process, save the time of occupying the table, and the effect of convenient installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

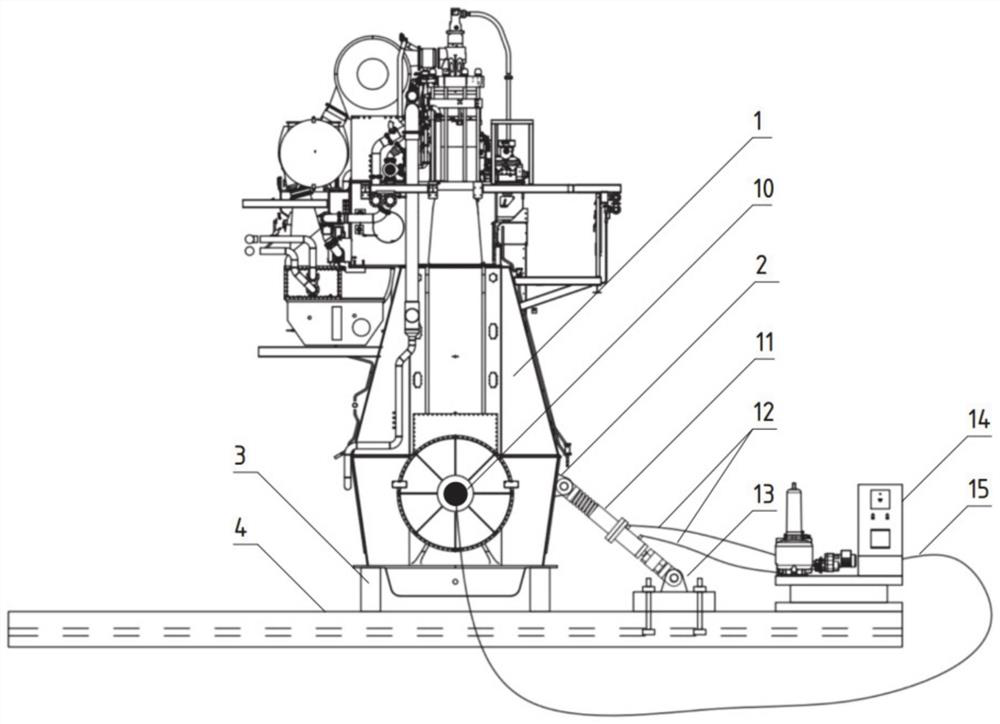

[0034] In a typical implementation of the present disclosure, such as Figure 1-Figure 3 As shown, a follow-up hydraulic damping device is proposed.

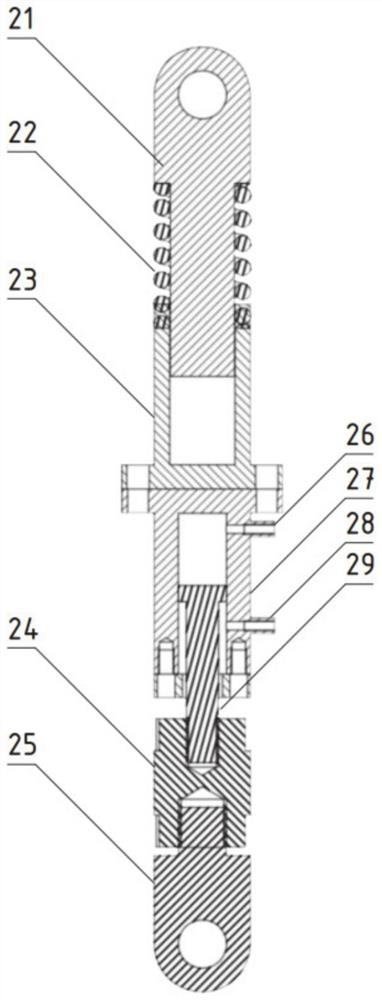

[0035] It mainly includes a hydraulic cylinder, an elastic expansion mechanism and a length adjustment mechanism, wherein one end of the hydraulic cylinder is connected to the elastic expansion mechanism, and the other end is connected to the ground rail fixed block through the length adjustment mechanism;

[0036] The hydraulic cylinder is used as a hydraulic support rod, and the two ends are respectively connected to the elastic telescopic mechanism and the length adjustment structure. The hydraulic support rod applies a given force to the vibration-damping equipment to change the natural frequency of the diesel engine test system. Taking a diesel engine as an example, it can reduce the vibration intensity at each speed of the diesel engine and avoid mechanical resonance under a specific load.

[0037] The elastic telescopic ...

Embodiment 2

[0058] In another typical implementation of the present disclosure, such as Figure 1-Figure 3 As shown, a hydraulic damping system is proposed.

[0059] It includes a plurality of follow-up hydraulic damping devices and control systems as described in Embodiment 1; wherein the hydraulic cylinder is connected to the hydraulic control station;

[0060] see figure 1 , two or four hydraulic support rods 11 are symmetrically distributed near the free end and driving end of the low-speed diesel engine 1, and the two ends are connected between the lifting ears 2 of the diesel engine base and the ground rail 4 of the platform; the diesel engine is installed on the on track.

[0061] By applying a given force to the diesel engine 1 through the hydraulic support rod 11 to change the natural frequency of the diesel engine test system, the vibration intensity at each speed of the diesel engine 1 can be reduced, and mechanical resonance under a specific load can be avoided.

[0062] Th...

Embodiment 3

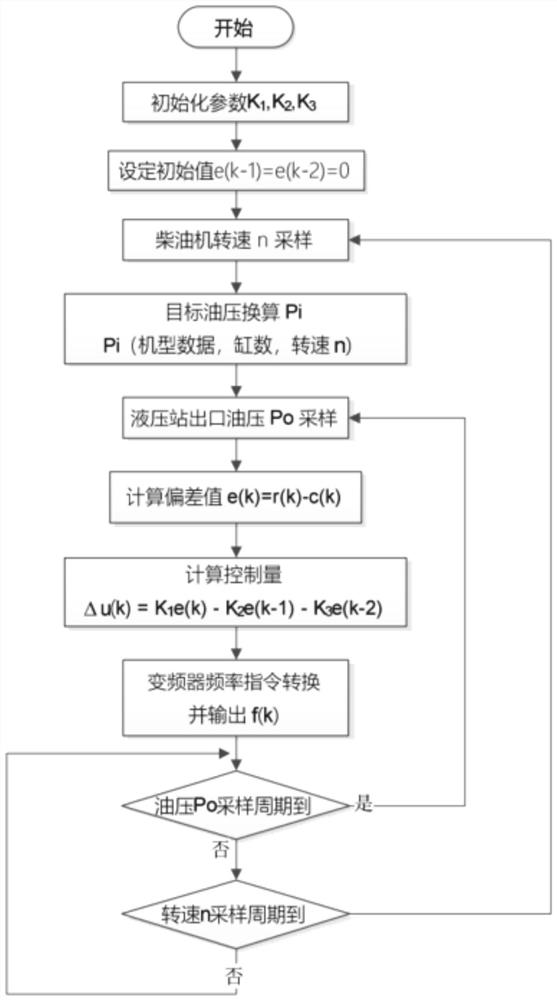

[0068] In yet another exemplary embodiment of the present disclosure, a hydraulic vibration damping method is provided.

[0069] Utilize the hydraulic damping system as disclosed in embodiment 2, comprising the following steps;

[0070] Fix multiple follow-up hydraulic damping devices and the equipment to be damped on the ground rail, and the corresponding multiple hydraulic cylinders are respectively connected to the hydraulic source, and the hydraulic cylinders are connected to the equipment to be damped through elastic telescopic mechanisms;

[0071] The following hydraulic damping device is tensioned by the length adjustment mechanism, so that the spring is at the zero position and the hydraulic cylinder is at the initial position;

[0072] After the damping equipment is started, drive the hydraulic cylinder to act, change the effect of the follow-up hydraulic damping device on the damping equipment, and adjust the vibration parameters of the damping equipment until the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com