Mooring cable for ship-borne platform

A tethering and cable technology, applied in the direction of insulated cables, communication cables, bendable cables, etc., can solve the problems of low tensile strength of tethered cables, affecting the safety of power transmission, signal transmission reliability, and poor water tightness, etc., to achieve Good structural stability, light weight, and the effect of improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

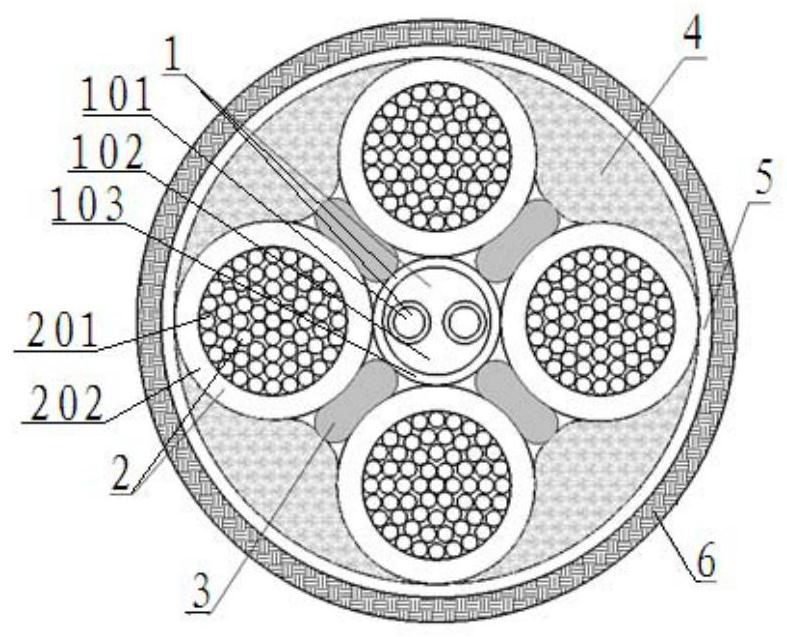

[0023] see figure 1 As shown: the present invention is a mooring cable for a shipboard platform, and the mooring cable includes an optical signal transmission unit 1, a power transmission unit 2, a tensile strength member 3, a water-blocking yarn 4, a water-blocking tape 5 and an outer sheath6. The present invention not only adopts the design of the tensile reinforcement 3 to improve the tensile performance, but also adopts the design of the water-blocking yarn 4 and the water-blocking tape 5 to improve the waterproof performance.

[0024] The number of groups of the above-mentioned optical signal transmission units 1 is one group, and the group of optical signal transmission units 1 includes a bending-resistant optical fiber 101 and a high-temperature-resistant tight cladding 102 and a stainless steel tape spiral armor that are sequentially coated on the outside of the bending-resistant optical fiber 101 The sheath layer 103, the high temperature resistant tight cladding lay...

Embodiment 2

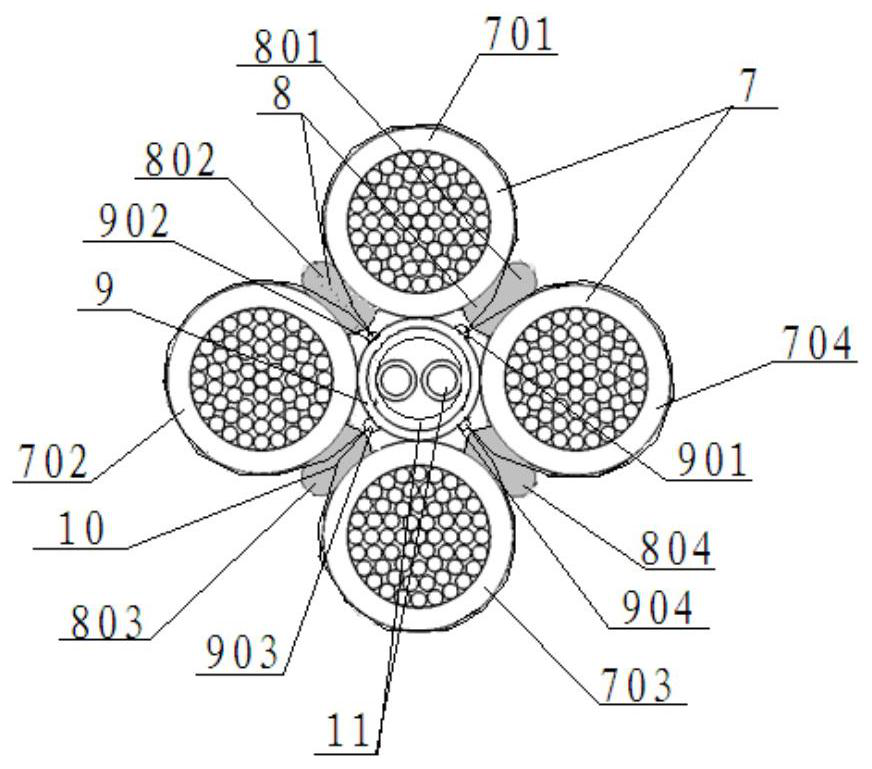

[0030] see figure 2 As shown: the other structure of this embodiment 2 is the same as that of embodiment 1, the difference is that: the mooring cable also includes a tapered roller bearing 9 and a connecting belt 10,

[0031] The power transmission units 7 are arranged parallel to each other along the length direction of the cable and evenly arranged around the optical signal transmission unit 11, which are respectively the first power transmission unit 701, the second power transmission unit 702, and the third power transmission unit 703. and a fourth power transmission unit 704 . Wherein, the power transmission unit 7 and the optical signal transmission unit 11 are also parallel to each other along the length direction of the cable.

[0032] There are multiple tapered roller bearings 9, which are evenly and spaced fixedly sleeved on the outer peripheral wall of the optical signal transmission unit 11 of the tethered cable. Tensile reinforcements 8 and water-blocking yarns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com