Optimized furniture drawer assembly structure

A technology for assembling structures and drawers, which is applied to drawers, furniture parts, household appliances, etc., can solve the problems that only wood drawers can be used, and the drawers cannot be quickly disassembled and assembled, so as to improve the appearance, improve the user experience, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

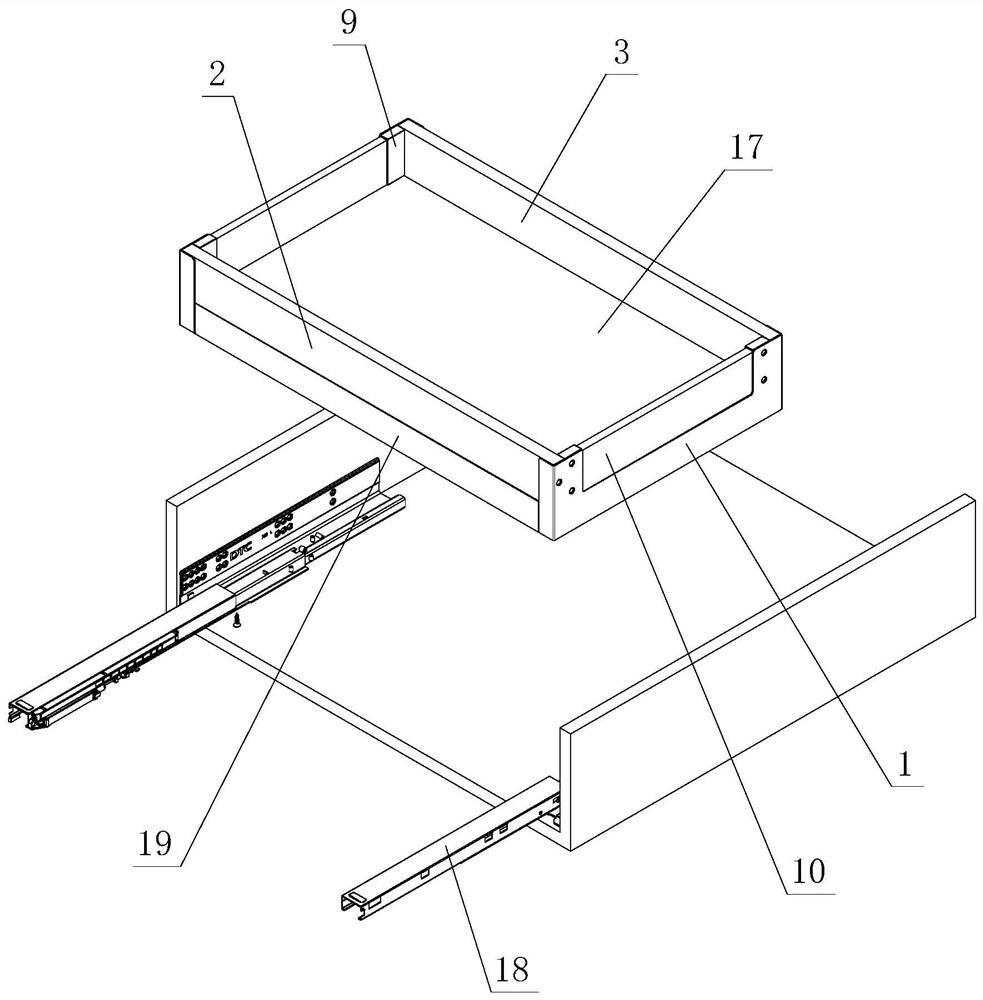

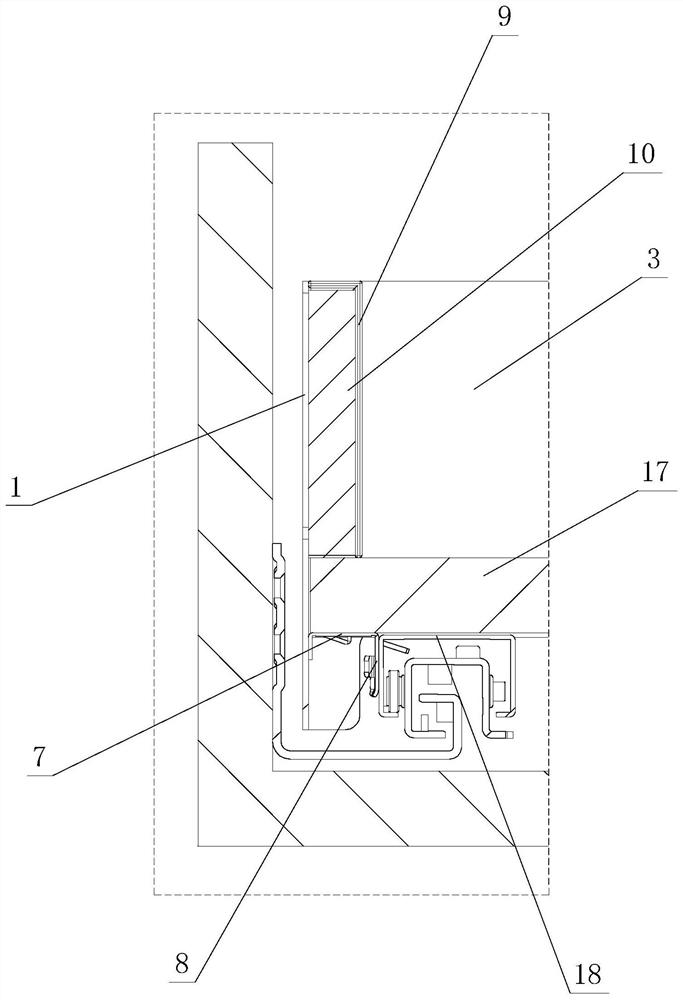

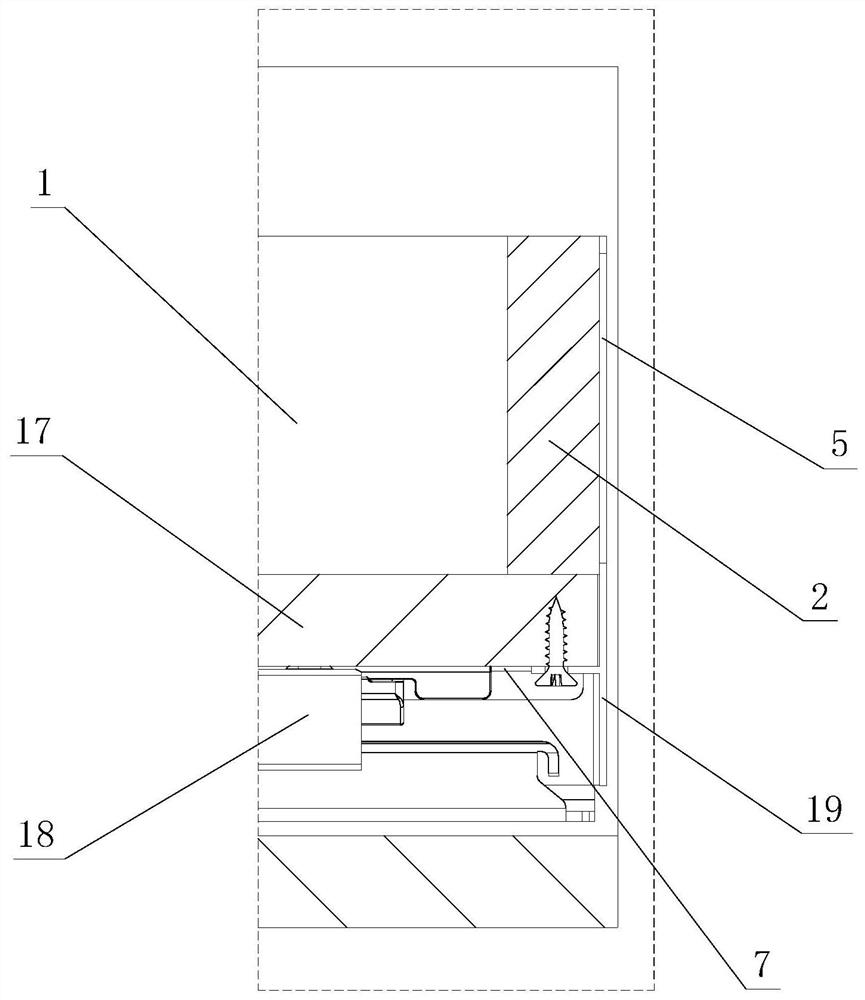

[0059] see Figure 1-Figure 22 , the optimized furniture drawer assembly structure includes a side panel 1, a front panel 2 and a rear panel 3, the side panel 1 is provided with a notch 4, and the front and rear ends of the side panel 1 are respectively integrally bent with a front bending part 5 and a rear panel. The bending part 6, the lower part of the side plate 1 is integrally formed or separately provided with a supporting part 7, and the supporting part 7 is integrally formed downward or separately provided with a relying part 8; the side plate 1 is also provided with an adapter 9 And the assembly plate 10, wherein the adapter 9 is fixedly arranged at the end of the side plate 1.

[0060] The assembly plate 10 is fixedly arranged on the notch portion 4 of the side plate 1 , or is arranged on the adapter piece 9 and is fixedly arranged on the notch portion 4 of the side plate 1 through the adapter piece 9 .

[0061] The front plate 2 and the rear plate 3 are directly fi...

no. 2 example

[0095] see Figure 23-Figure 25 , the optimized furniture drawer assembly structure differs from the first embodiment in that: the front and rear ends of the assembly plate 10 are directly fixedly connected to the front side wall 11 and the rear side wall 12 and are located in the notch 4 .

[0096] The front panel 2 and the rear panel 3 are respectively arranged on the adapter piece 9 and fixedly arranged on the side panel 1 through the adapter piece 9 respectively.

[0097]The front and back of the assembly plate 10 are directly connected with the front side wall 11 and the rear side wall 12 of the side plate 1, and the front plate 2 and the rear plate 3 are fixedly arranged on the side plate 1 by using the adapter 9 to form the outer frame of the drawer The shape effectively avoids the problem that the front panel 2 and the rear panel 3 need to be fixed with fasteners during assembly, so as to simplify the assembly process between the side panel and the front panel 2 and th...

no. 3 example

[0106] see Figure 26-Figure 28 , the optimized furniture drawer assembly structure is different from the first embodiment in that: the assembly plate 10, the front plate 2 and the rear plate 3 are respectively arranged on the adapter 9, and are respectively fixed by the adapter 9 on side panel 1.

[0107] The assembly panel 10, the front panel 2 and the rear panel 3 are respectively fixedly arranged on the side panel 1 with the adapter 9 to form the outer frame shape of the drawer, effectively avoiding the assembly panel 10, the front panel 2, and the rear panel 3 During assembly, it is necessary to install fasteners on it to fix the problem, so as to simplify the assembly process between the side panel and the assembly panel 10 , the front panel 2 and the rear panel 3 .

[0108] Due to the transfer assembly of the adapter piece 9, not only can the assembly firmness between the side plate 1 and the assembly plate 10, the front plate 2, and the rear plate 3 be improved, but a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com