Rectification process real-time monitoring method based on online sampling data driving

A technology of sampling data and real-time monitoring, applied in fractionation, measuring devices, complex mathematical operations, etc., can solve problems such as lack of fault data and inability to know, and achieve the effect of simple and clear implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

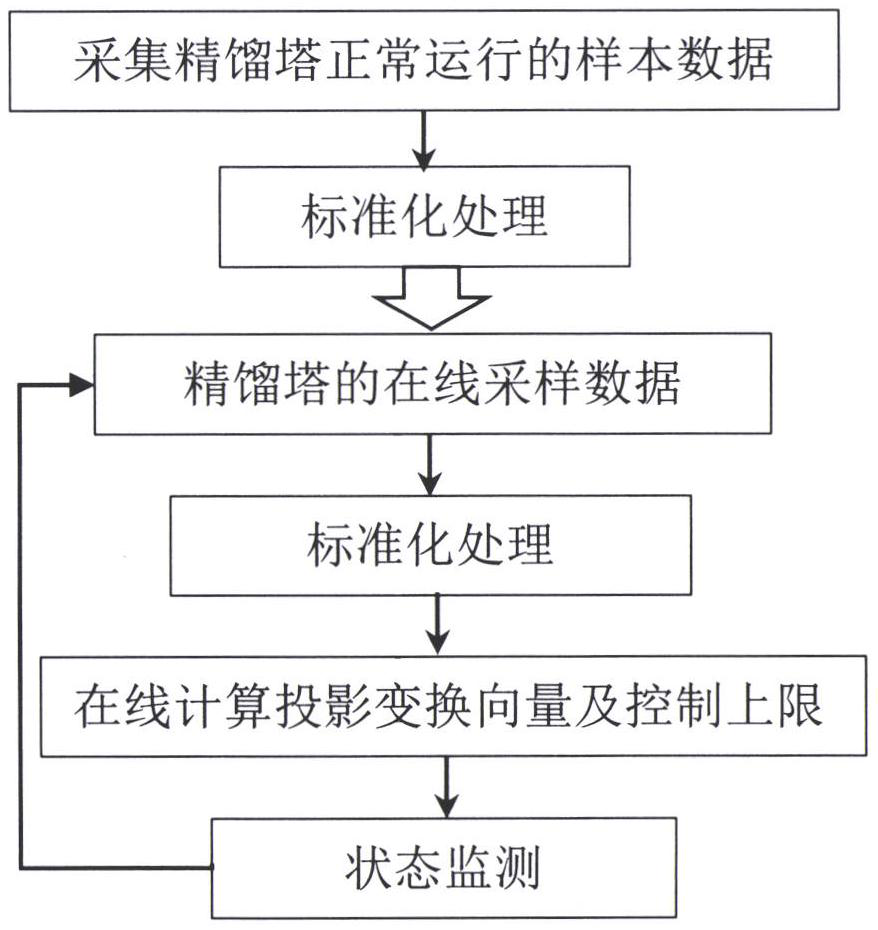

[0029] like figure 1 As shown, the present invention discloses a method for real-time monitoring of the rectification process driven by online sampling data. The specific implementation of the method of the present invention will be described below in conjunction with a specific application example.

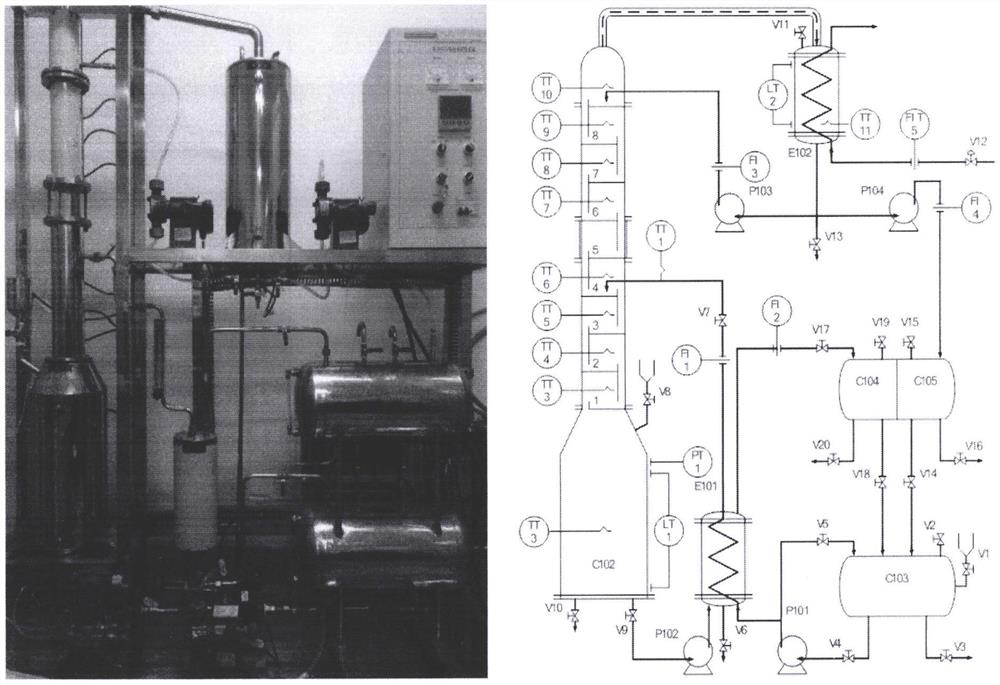

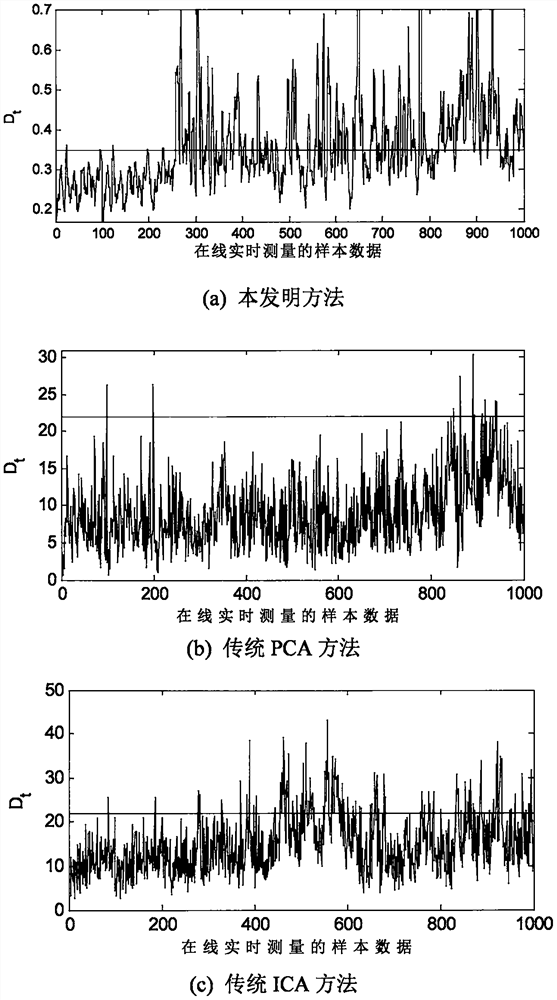

[0030] from figure 2 It can be seen from the actual picture of the rectification tower in the figure that the rectification tower equipment is not only a single rectification equipment, but also has a supporting reboiler at the bottom and a condenser at the top. from figure 2 It can be seen from the structural diagram in the figure that the measuring instruments of the rectification tower equipment include: flow meter, temperature meter, and liquid level meter. There are 17 variables corresponding to the measurement, including: tower still l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com