Wood leaf functional cup based on pore-forming process and preparation method thereof

A technology of wood leaves and craftsmanship, applied in the field of wood leaf functional cups and its preparation based on pore-making technology, can solve the problems of affecting the firing efficiency of wood leaf cups, no precipitation, limited precipitation of trace elements, etc., and meet the firing conditions Stable and reliable, increased yield, and increased porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

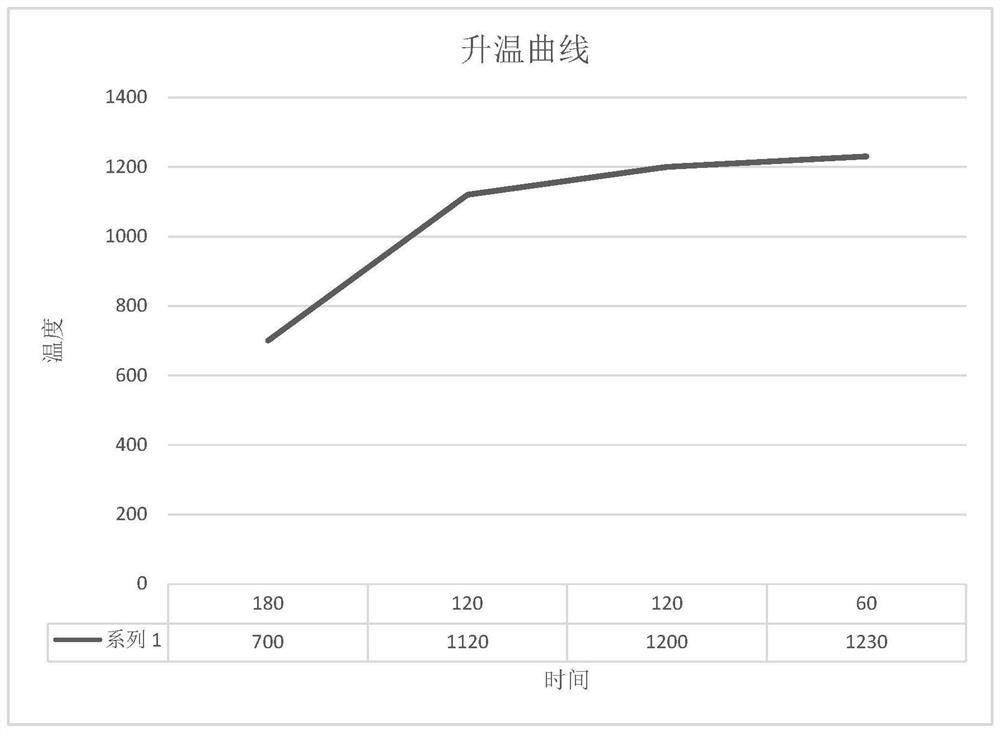

[0029] A method for preparing a wood-leaf functional cup based on a pore-making process, using the following steps:

[0030] (1) In the ball mill, according to the specific gravity of 1:0.7, put the composition of the glaze and water into the ball mill for ball milling, specifically: add the powder in the following weight ratio: K 2 O 6%, Na 2 O 2%, CaO 4%, Al 2 o 3 15%, Fe 2 o 3 4%, SiO 2 62%, P 2 o 5 0.3%, TiO 2 1%, MnO 2 0.1%, and water; the balls in the ball mill tank should not exceed 1 / 2 of the tank volume, and the ball milling time is about 60 minutes to ensure that the ball mill particles can pass through the 120-mesh sieve to obtain the required glaze;

[0031] (2) Clay used: red kaolin 28%, white kaolin 7%, Tuogou pottery clay 27%, feldspar 13%, quartz 4%, CaCO 3 9%, MgO 0.08%, SrO 0.7%, Fe 2 o 3 0.8%, SiO 2 0.6%, TiO 2 0.3%, Na 2 O 0.06%, K 2 O0.01%, prepare the mud base of 2-3mm thickness, after 850 ℃ of low-temperature biscuits, use the met...

Embodiment 2

[0035] A method for preparing a wood-leaf functional cup based on a pore-making process, comprising the following steps:

[0036] (1) In the ball mill, according to the specific gravity of 1:0.7, put the composition of the glaze and water into the ball mill for ball milling, specifically: add the powder in the following weight ratio: K2 O 6%, Na 2 O 2%, CaO 4%, Diatomaceous Earth 6%, Al 2 o 3 15%, Fe 2 o 3 6%, SiO 2 62%, P 2 o 5 0.4%, TiO 2 1%, MnO 2 0.1%, and water; the balls in the ball mill tank should not exceed 1 / 2 of the tank volume, and the ball milling time is about 65 minutes to ensure that the ball mill particles can pass through the 120-mesh sieve to obtain the required glaze;

[0037] (2) Equipped with mud materials 27% red kaolin, 7% white kaolin, 27% Tuogou pottery clay, 12% feldspar, 4% quartz, CaCO 3 9%, MgO 0.08%, SrO 0.7%, Fe 2 o 3 0.8%, SiO 2 0.6%, TiO 2 0.3%, Na 2 O 0.06%, K 2 O0.01%, prepare the mud base of 2-3mm thickness, after 850...

Embodiment 3

[0041] A method for preparing a wood-leaf functional cup based on a pore-making process, comprising the following steps:

[0042] (1) In the ball mill, according to the specific gravity of 1:0.7, put the composition of the glaze and water into the ball mill for ball milling, specifically: add the powder in the following weight ratio: K 2 O 6%, Na 2 O 2%, CaO 4%, Diatomaceous Earth 3%, Al 2 o 3 15%, Fe 2 o 3 6%, SiO 2 62%, P 2 o 5 0.8%, TiO 2 1%, MnO 2 0.1%, and water; the balls in the ball mill tank should not exceed 1 / 2 of the tank volume, and the ball milling time is about 100 minutes to ensure that the ball mill particles can pass through the 120-mesh sieve to obtain the required glaze;

[0043] (2) Use clay red kaolin 28% red kaolin, 8% white kaolin, 26% Tuogou pottery clay, 12% feldspar, 4.5% quartz, CaCO 3 1.5%, MgO 0.08%, SrO 0.8%, Fe 2 o 3 0.8%, SiO 2 0.6%, TiO 2 0.3%, Na 2 O0.08%, K 2 O 0.008%, prepare a mud base with a thickness of 2-3mm, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com