Two-component polyurethane paint and preparation method thereof

A two-component polyurethane and one-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of paint film loss, yellowing, and expansion tank foam, etc., and achieves convenient operation, simple preparation process, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Second aspect, the present invention provides a kind of preparation method of two-component polyurethane paint, comprises the steps:

[0063] S01. Carrying out the first mixing treatment of alkyd resin, filler, dispersant, defoamer, matting powder, and butyl acetate to obtain the first mixture;

[0064] S02. The first mixture is subjected to a second mixing treatment with the dustproof agent, leveling agent, and dehydrating agent containing -NCO-groups to obtain the first component;

[0065] S03. An inert atmosphere is provided, and the butyl acetate and the dehydrating agent containing -NCO-groups are subjected to a third mixing treatment to obtain a second mixture;

[0066] S04. Perform a fourth mixing treatment on the second mixture and the curing agent to obtain the second component.

[0067] In the preparation method of the two-component polyurethane paint, the components of the first component and the components of the second component are respectively mixed to p...

Embodiment 1

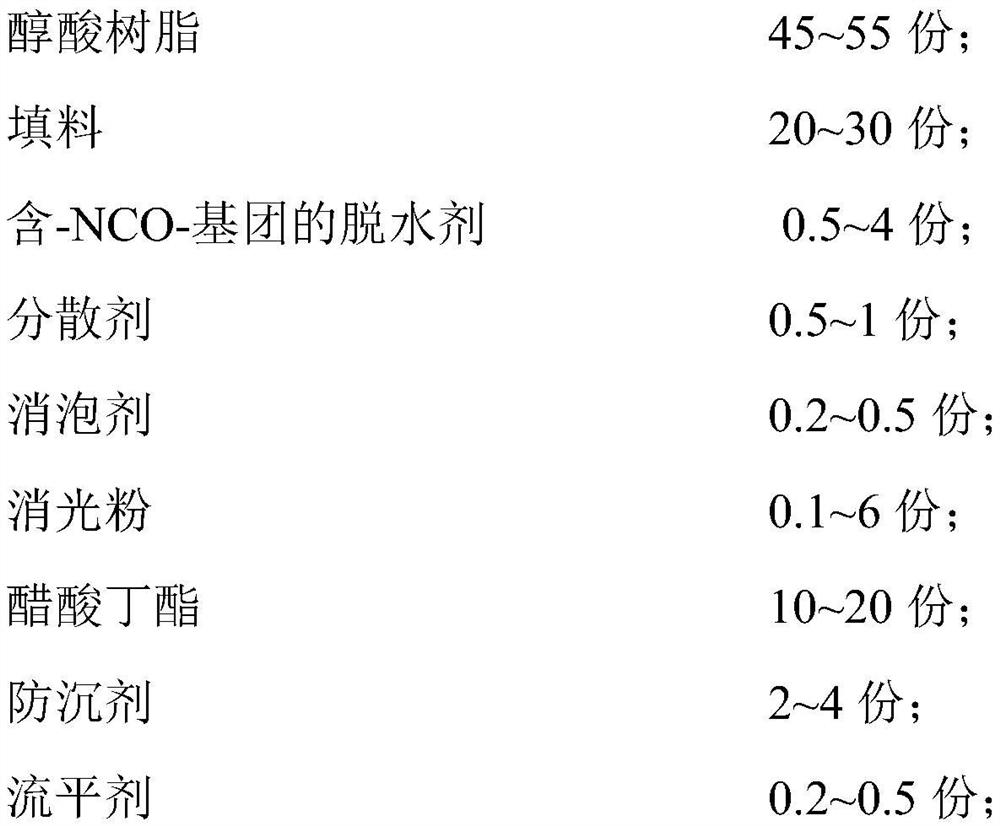

[0077] Two-component polyurethane paint

[0078] The two-component polyurethane paint comprises a first component and a second component, wherein the first component comprises the following components in the following parts by weight:

[0079]

[0080] The second component includes the following components in the following parts by weight:

[0081] 69 parts of curing agent;

[0082] 30 parts of butyl acetate;

[0083] 1 part of dehydrating agent containing -NCO- group.

[0084] Wherein, the alkyd resin is selected from soybean oil alkyd resin with an oil degree≤40%, a solid content of 70%, and an acid value of 12 mg KOH / g;

[0085] The dehydrating agent containing -NCO-group is selected from p-toluenesulfonyl isocyanate;

[0086] The filler is selected from calcium carbonate;

[0087] The dispersant is selected from unsaturated polycarboxylic acid polymers;

[0088] Defoamer is selected from polysiloxane defoamer;

[0089] The matting powder is selected from silica-...

Embodiment 2

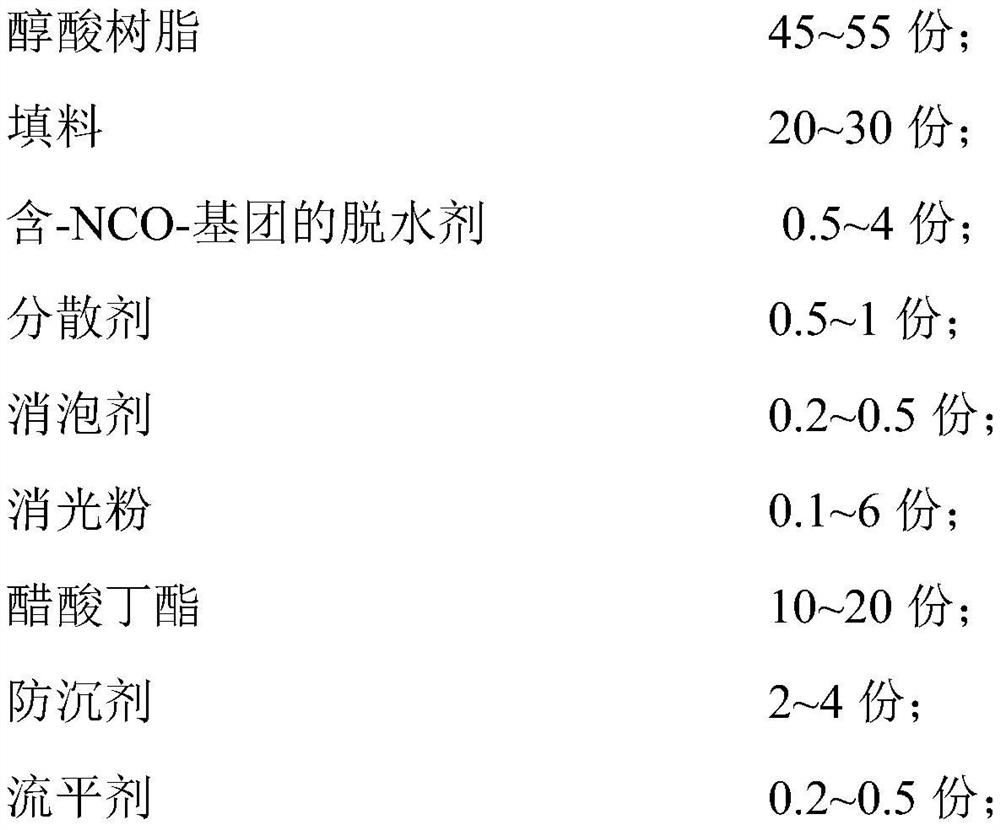

[0100] Two-component polyurethane paint

[0101] The two-component polyurethane paint comprises a first component and a second component, wherein the first component comprises the following components in the following parts by weight:

[0102]

[0103] The second component includes the following components in the following parts by weight:

[0104] 61 parts of curing agent;

[0105] 35 parts of butyl acetate;

[0106] 4 parts of dehydrating agent containing -NCO- group.

[0107] Wherein, the alkyd resin is selected from soybean oil alkyd resin with an oil degree≤40%, a solid content of 70%, and an acid value of 12 mg KOH / g;

[0108] The dehydrating agent containing -NCO-group is selected from p-toluenesulfonyl isocyanate;

[0109] The filler is selected from calcium carbonate;

[0110] The dispersant is selected from unsaturated polycarboxylic acid polymers;

[0111] Defoamer is selected from polysiloxane defoamer;

[0112] The matting powder is selected from silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap