Shape memory alloy ring spring set and assembly type self-resetting pier system

A technology of self-resetting bridge piers and memory alloys, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of increased consumption of shape memory alloys, material residues, high cost, etc., to reduce repair work, avoid residual deformation, and simplify construction program effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

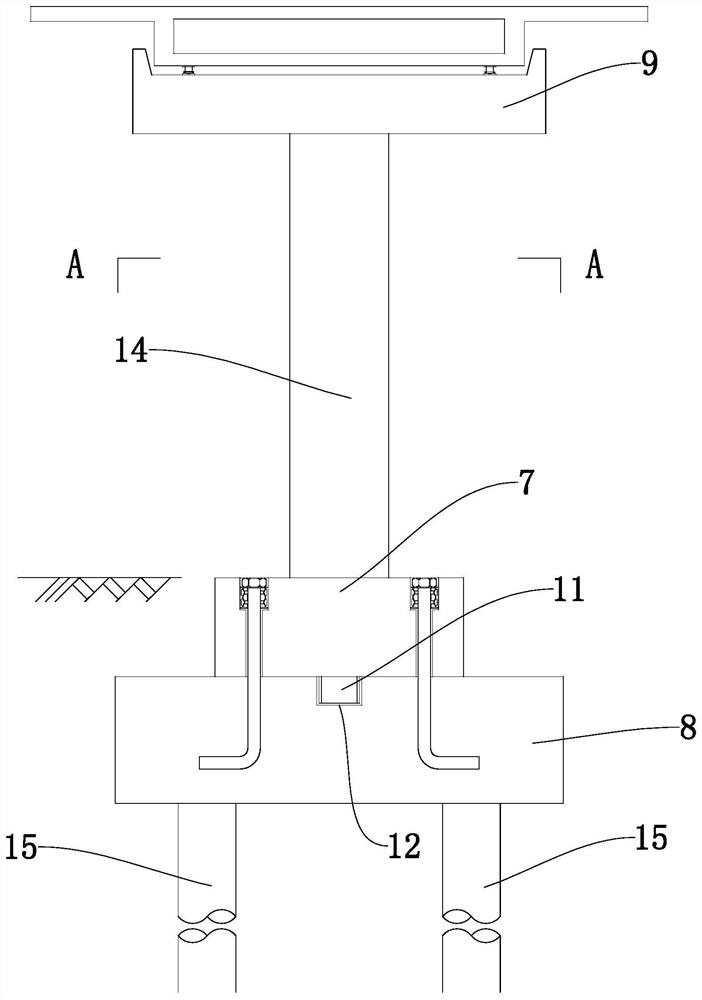

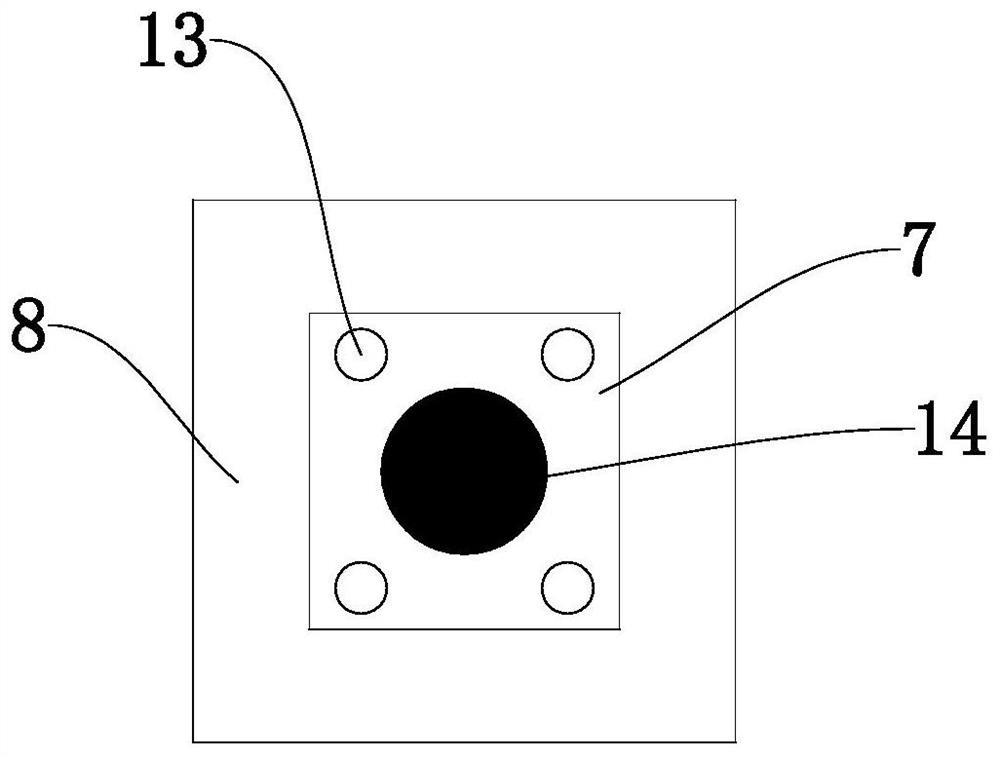

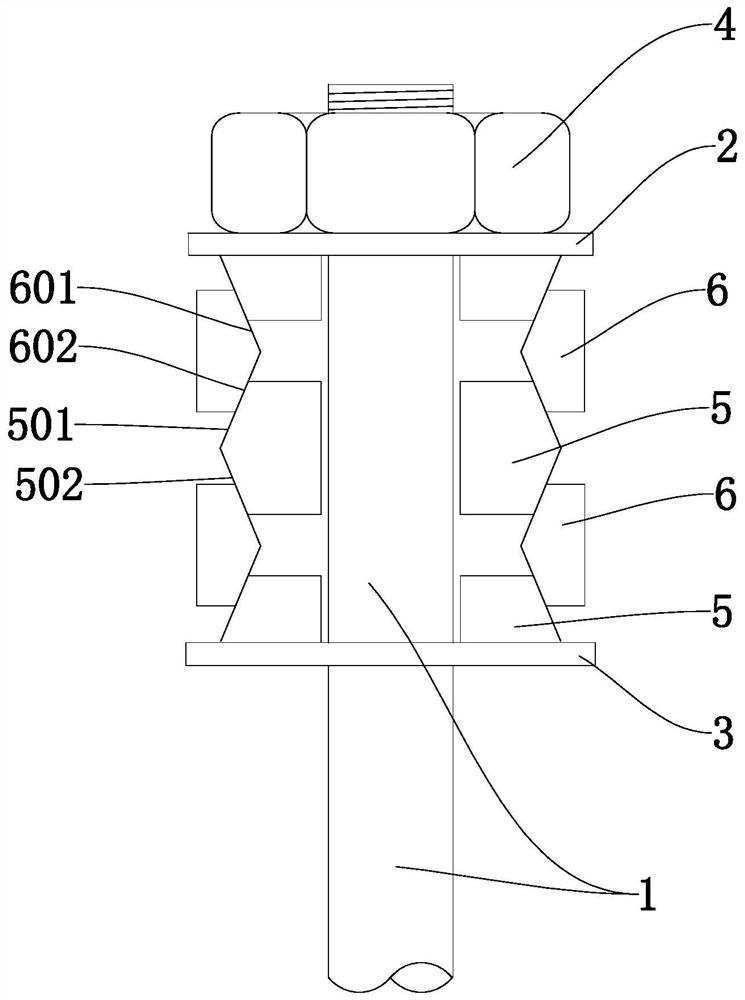

[0033] This embodiment is an assembled self-resetting bridge pier system based on a shape memory alloy ring spring group, including a prefabricated extended foundation, a cast-in-place cap, a pier body and a cover beam. The cast-in-place cap is connected to the pile foundation below, the prefabricated extended foundation is placed on the cast-in-place cap and connected by 4 shape memory alloy ring spring groups, and the top of the prefabricated extended foundation is connected to the cover beam through the pier body. The bottom of the extended foundation is provided with a shear key; the top surface of the cast-in-place cap is reserved to match the shear key at the bottom of the prefabricated extended foundation.

[0034] In this example, the geometric shape of the prefabricated extended foundation is a cube, and the top-view plan shape is a rectangle. Without loss of generality, it is recommended that the top-view plan shape of the prefabricated extended foundation be square. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com