Devices for dry gas sealing of compressors

A technology of dry gas sealing and compressor, which is applied in the sealing device of piston pump, liquid tightness measurement using liquid/vacuum degree, mechanical equipment, etc. Problems such as the service life of the pressure pump, to achieve the effect of saving external sealing gas, improving the service life and reducing the running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

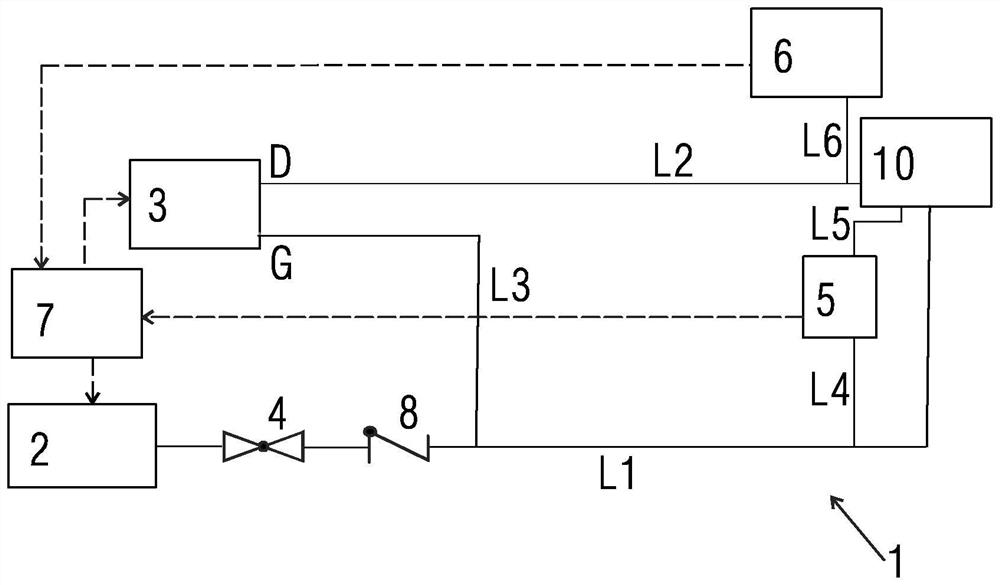

[0056] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

[0057] In the figures, the actual line connections are marked with solid lines and the connections of the signal lines are marked with dashed lines.

[0058] figure 1 A device 1 for dry gas sealing of a compressor according to the invention is shown. The device 1 has: a detection mechanism 6, the detection mechanism detects the gas pressure inside the compression cylinder of the compressor 10, and obtains a first pressure value and a first pressure value signal indicating the first pressure value; the booster pump 3, When the booster pump is turned on, a part of the gas in the compression cylinder is delivered to the booster pump, and the booster pump pressurizes the pressure of the part of the gas to a second pressure value through space c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com