Clutch

A clutch and meshing pair technology, applied in the field of clutches, can solve the problems affecting the performance of the clutch, the failure of the outer spline of the center sleeve, and the short length of the positioning guide, so as to improve the comfort and commerciality, increase the service life, and combine fast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

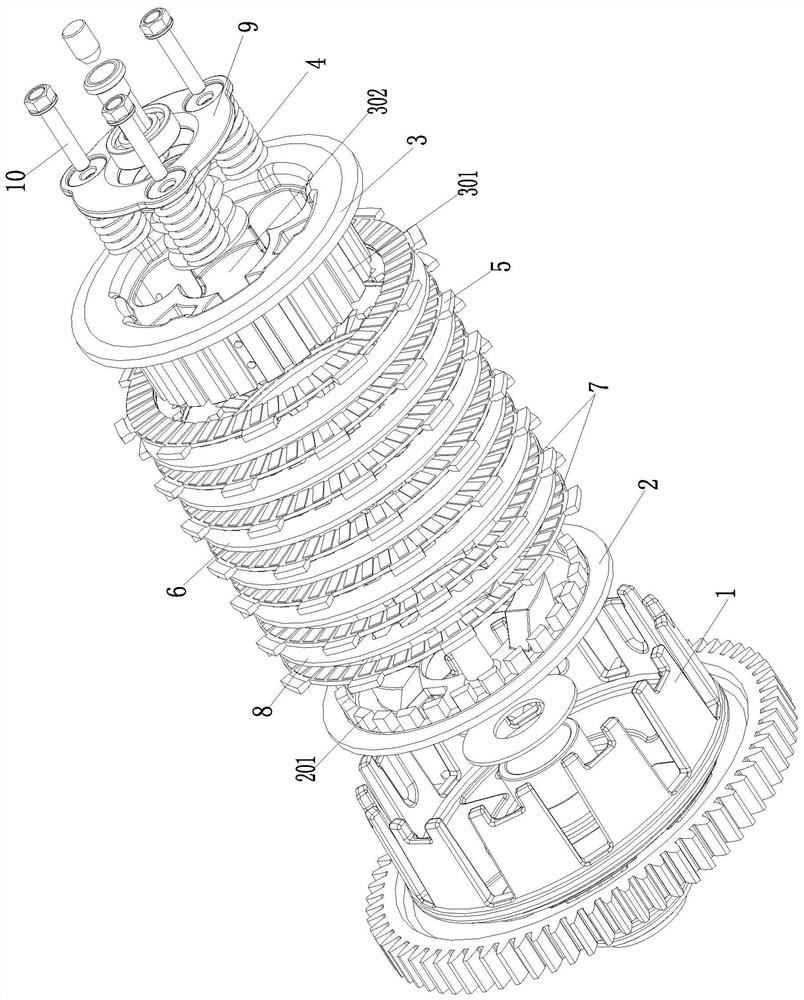

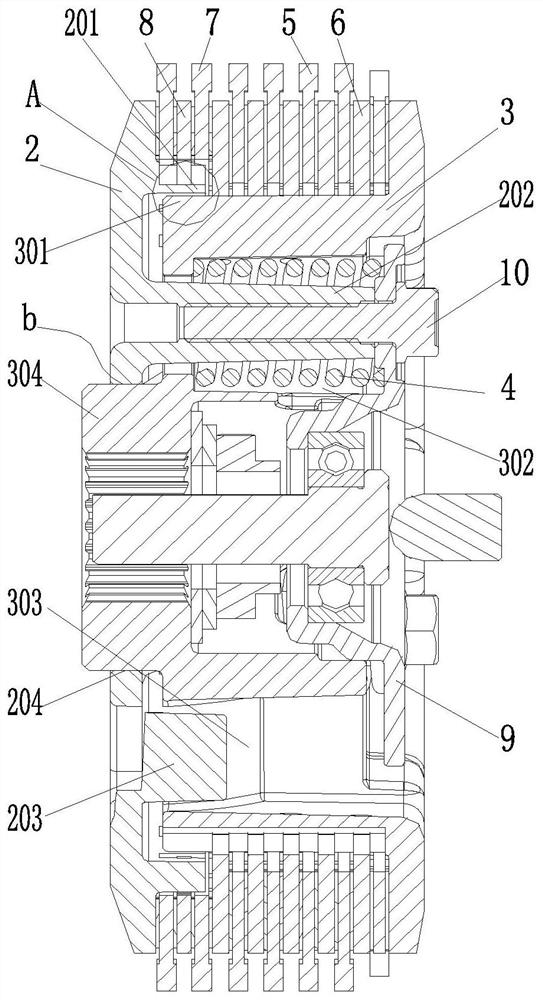

[0037] As shown in the figure, the clutch of this embodiment includes a pressure plate 2, a friction plate assembly and a center sleeve 3;

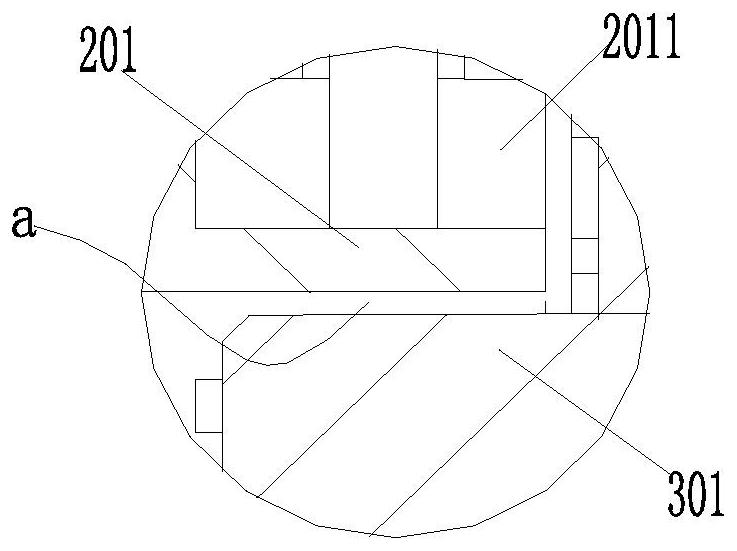

[0038] The pressure plate 1 is provided with a positioning guide part that cooperates with the center sleeve 3 in the vicinity of the center sleeve outer spline 301 to form radial positioning and axial guidance, and the positioning guide part and the center sleeve 3 form a positioning guide structure a;

[0039] The engagement between the pressing plate and the center sleeve is also formed through the helical tooth engagement pair on the end face;

[0040] The structure of the clutch certainly includes parts such as outer cover 1, pressure plate 2, center sleeve 3, lifting plate 9, main spring 4, friction plate assembly (active friction plate 5 is arranged on outer cover 1, driven friction plate 6 is arranged on center sleeve 3), and pressure plate 2 or the center sleeve 3 is provided with a spring seat sinking groove for accommodating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com