Clamping stagnation prevention clutch

A clutch and anti-seize technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve problems such as stumbling and slow clutch separation, and achieve the effect of eliminating vibrato, avoiding engine braking, and reducing force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

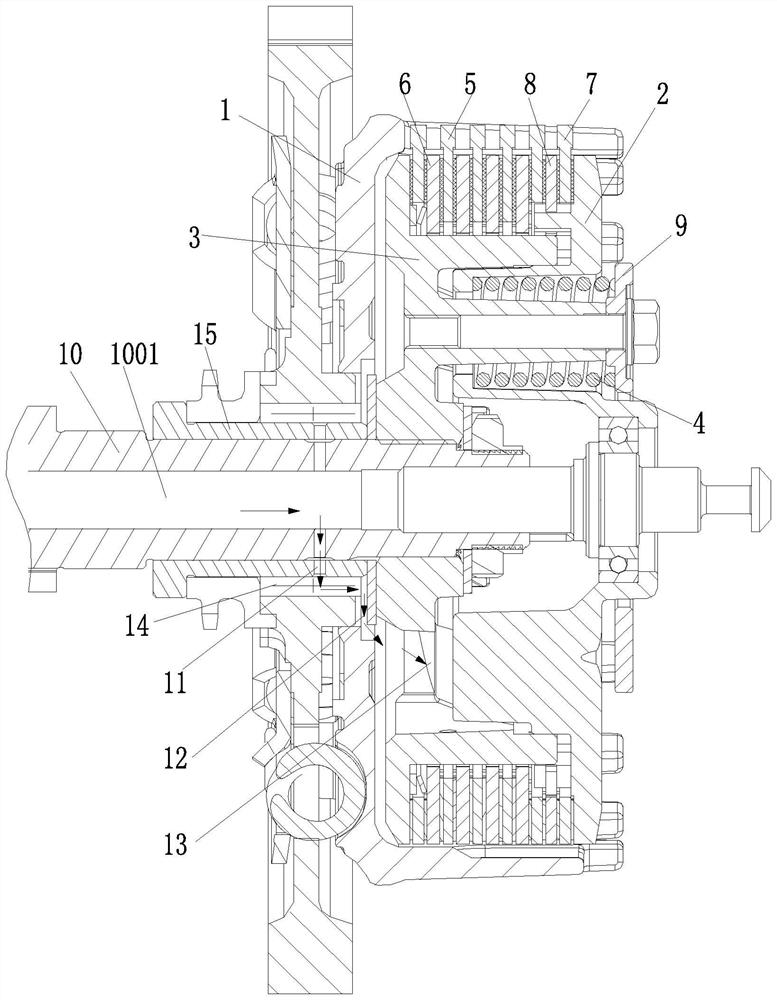

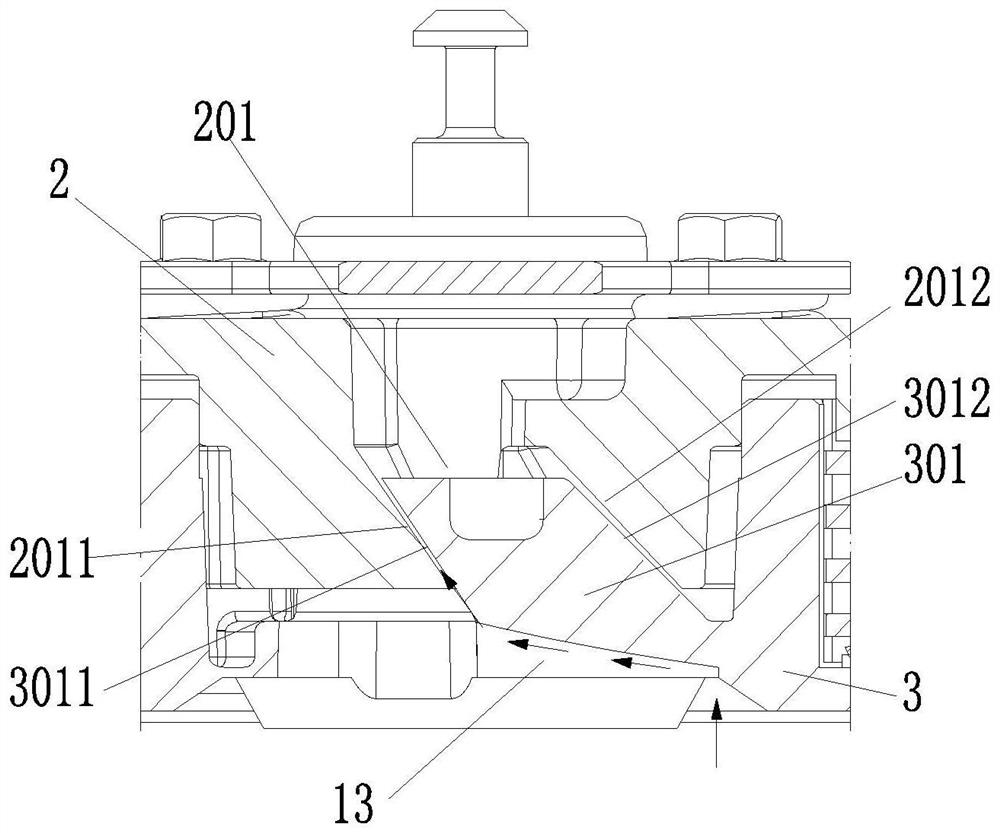

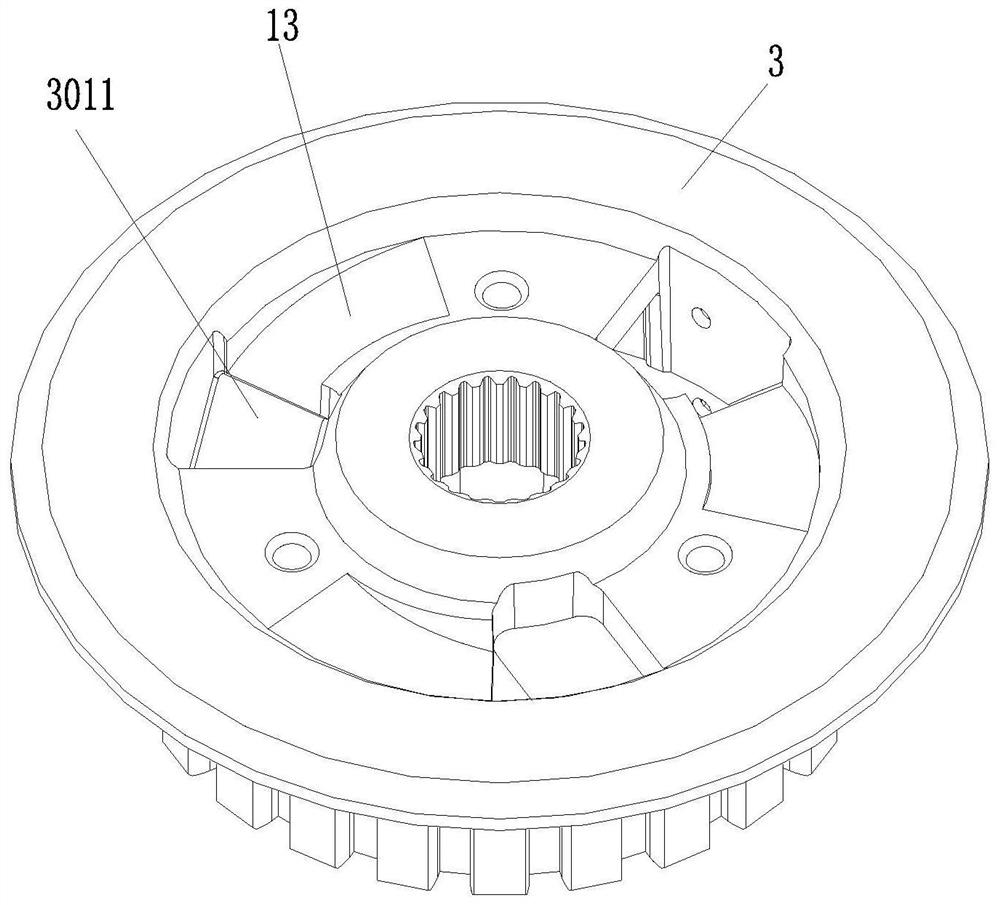

[0036] As shown in the figure, the anti-seize clutch of this embodiment includes a pressure plate 2, a friction plate assembly and a center sleeve 3; including a pressure plate, a friction plate assembly and a center sleeve;

[0037] There is a clearance for relative rotation in the circumferential direction between the pressure plate and the center sleeve, and the engagement between the pressure plate and the center sleeve is formed by an end helical tooth meshing pair;

[0038] The clutch also includes a helical tooth lubricating channel for leading lubricating oil to the helical tooth meshing pair on the end face;

[0039] The structure of the clutch belongs to the prior art, and certainly includes an outer cover 1, a pressure plate 2, a center sleeve 3, a lifting plate 9, a main spring 4, and a friction plate assembly (the active friction plate 5 is arranged on the outer cover 1, and the driven friction plate 6 is arranged on the center sleeve 3 ) and other parts, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com