Self-expansion anti-seepage high-pressure sealing element for petroleum exploitation equipment

A high-pressure sealing and oil extraction technology, applied in mechanical equipment, engine sealing, engine components, etc., can solve the problems of huge manpower and material resources, performance degradation of seals, accelerated aging of seals, etc., to improve work safety, improve The effect of sealing and avoiding contact shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

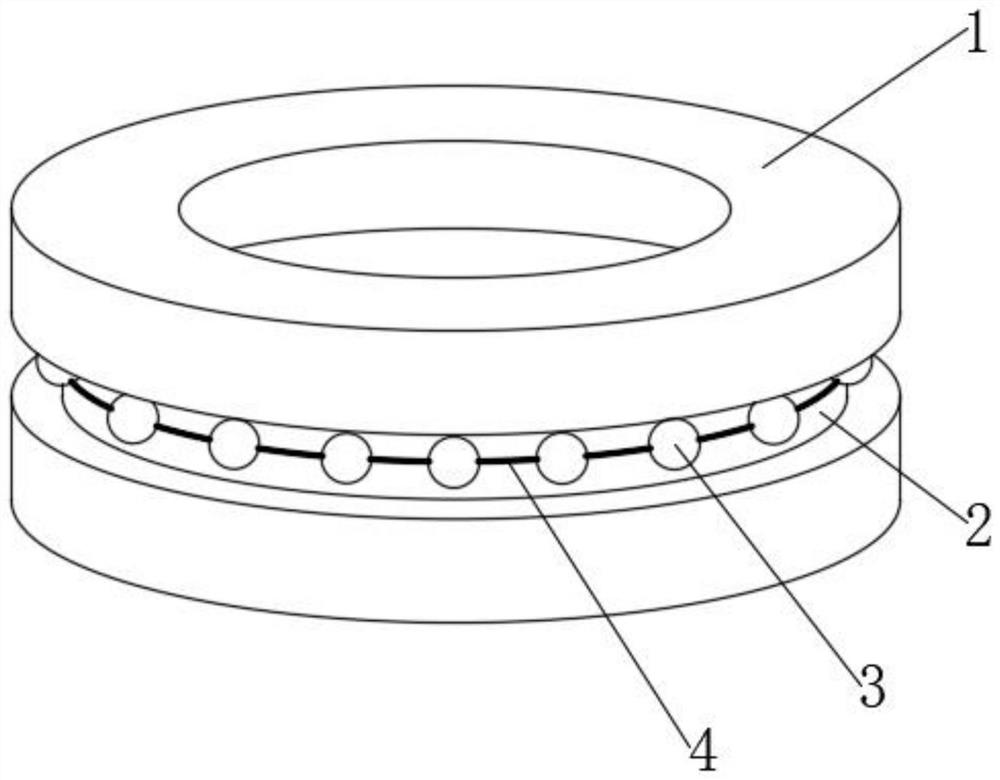

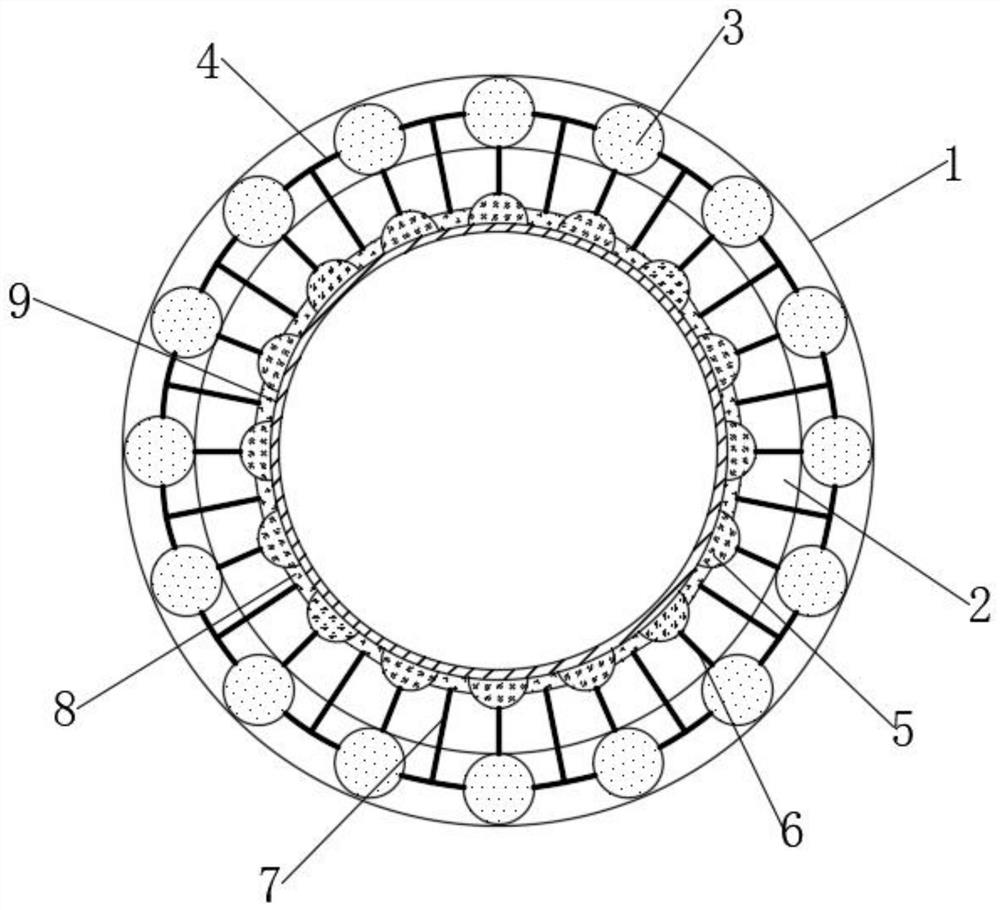

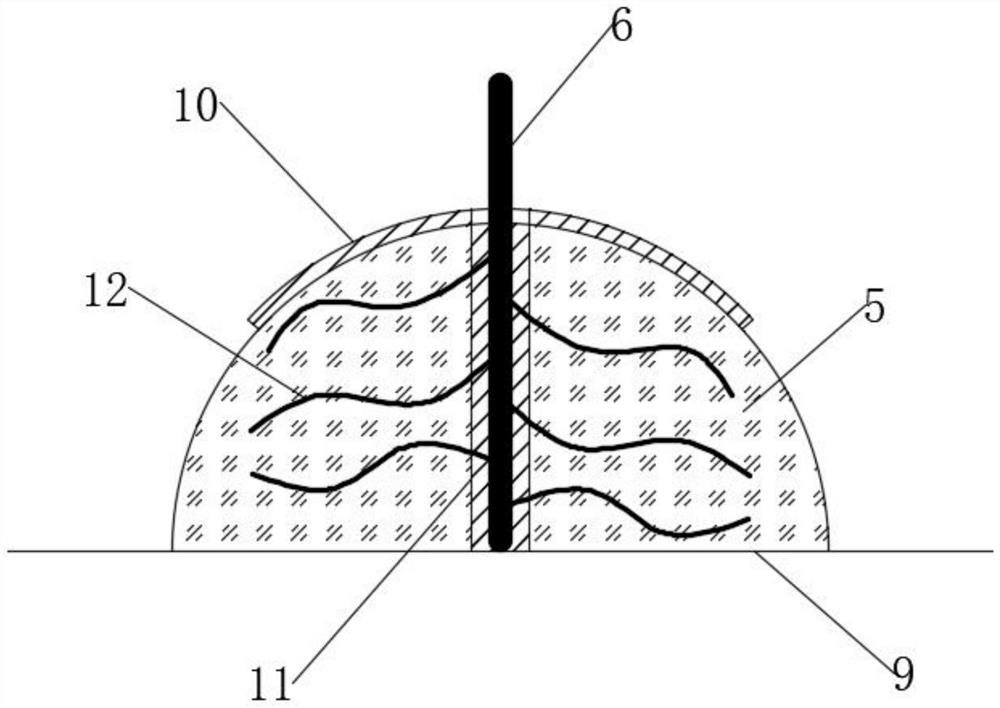

[0040] see Figure 1-2 , a self-expanding anti-seepage high-pressure seal for oil extraction equipment, including a pair of edge sealing rings 1 and embedded sealing rings 2, the edge sealing rings 1 and embedded sealing rings 2 are made of oil-resistant rubber, and the embedded sealing rings The ring 2 is inlaid between a pair of edge sealing rings 1, and the pair of edge sealing rings 1 and the embedded sealing ring 2 are integrally formed, and the outer surface of the embedded sealing ring 2 is fixedly connected with a plurality of permeable oil-absorbing balls 3 distributed in an annular array , the inner surface of the embedded sealing ring 2 is fixedly connected with the fixed ring 9, the fixed ring 9 is made of hard material, which plays the role of supporting and shaping the embedded sealing ring 2 and the expansion limiting piece 10, and the fixed ring 9 is close to One end of the embedded sealing ring 2 is fixedly connected with a plurality of oil expansion trigger h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com