Reusable electric explosion valve

A valve and electric explosion technology, applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve the problems of poor economy of aerospace power systems, poor performance of aerospace power devices, and medium pollution, etc., to achieve improvement The number of times of repeated use, the wide range of applicable pressure, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

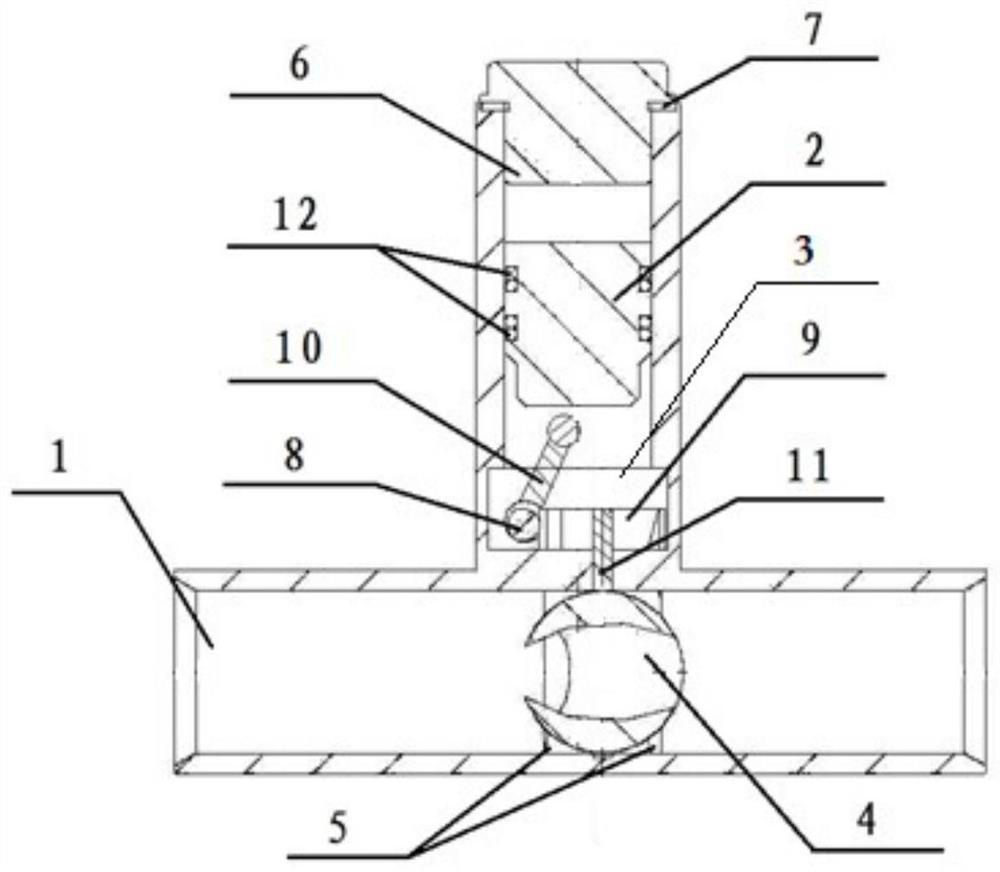

[0022] The reusable electric blast valve is further described below in conjunction with the accompanying drawings.

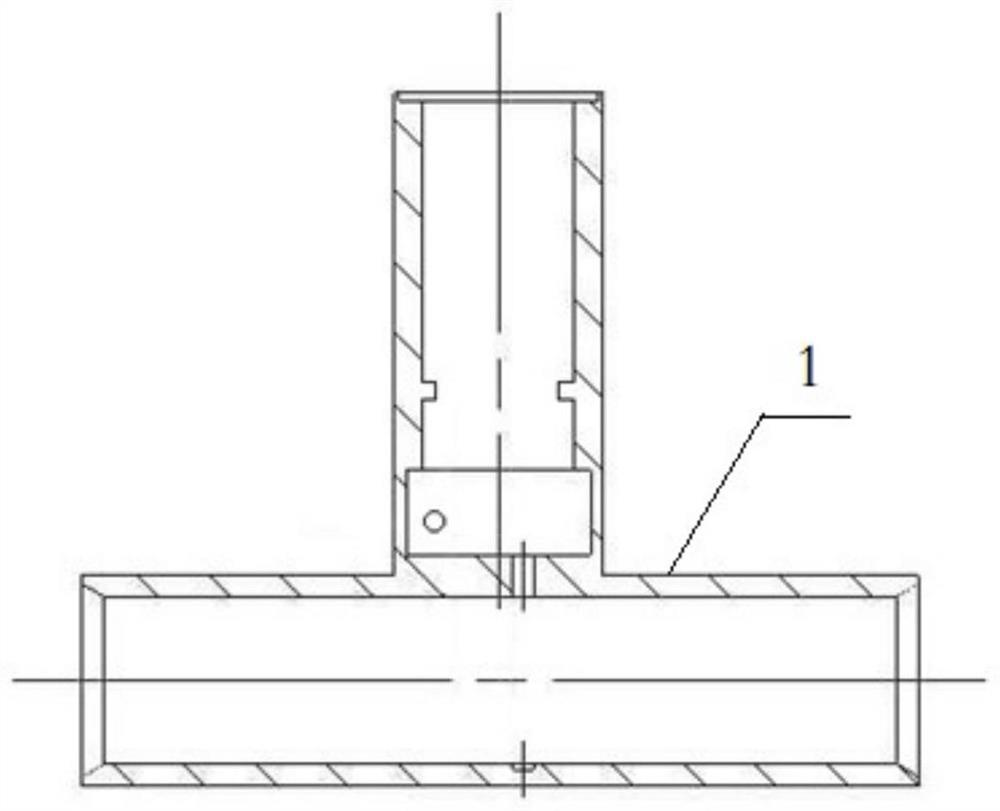

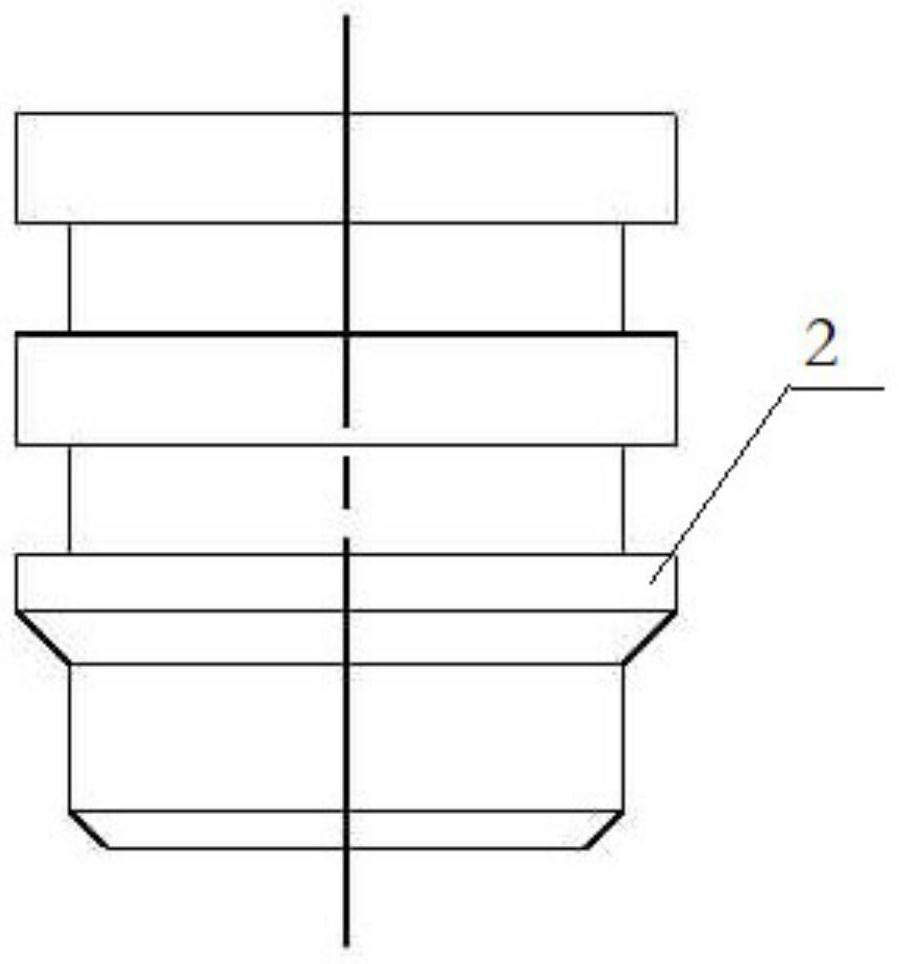

[0023] This reusable electric blast flap, such as Figure 1 , a reusable electric blast valve, including: housing 1, piston 2, transmission mechanism 3, valve ball 4, sealing ring 5, igniter 6, gasket 7, rubber ring 12. Piston 2 is placed in the upper middle end of housing 1, piston 2 front end is connected to the transmission mechanism 3, piston 2 tail end is connected to igniter 6 by glue, piston 2 has a rubber ring 12 between the shell 1, for blocking impurities generated by ignition of ignition 6. Igniter 6 is mounted at the upper end of housing 1 and sealed by gasket 7. Transmission mechanism 3 is mounted and fixed in housing 1, transmission mechanism 3 and valve ball 4 are connected.

[0024] as Figure 4 The transmission mechanism apparatus shown 3, comprising: worm 8, worm gear 9, rotary rod 10, mounting shaft 11. The tail end of the rotary rod 10 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com