Steel bell and spigot pipeline limiting joint

A socket and pipe technology, applied in the direction of pipes/pipe joints/fittings, non-removable pipe connections, through components, etc., can solve problems such as reducing installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

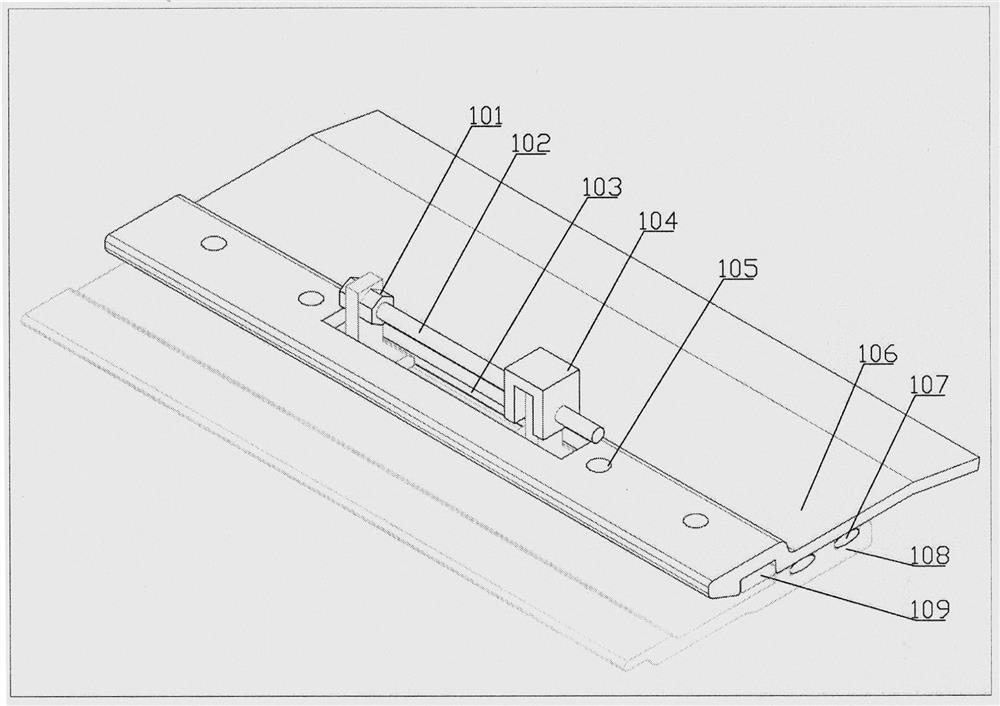

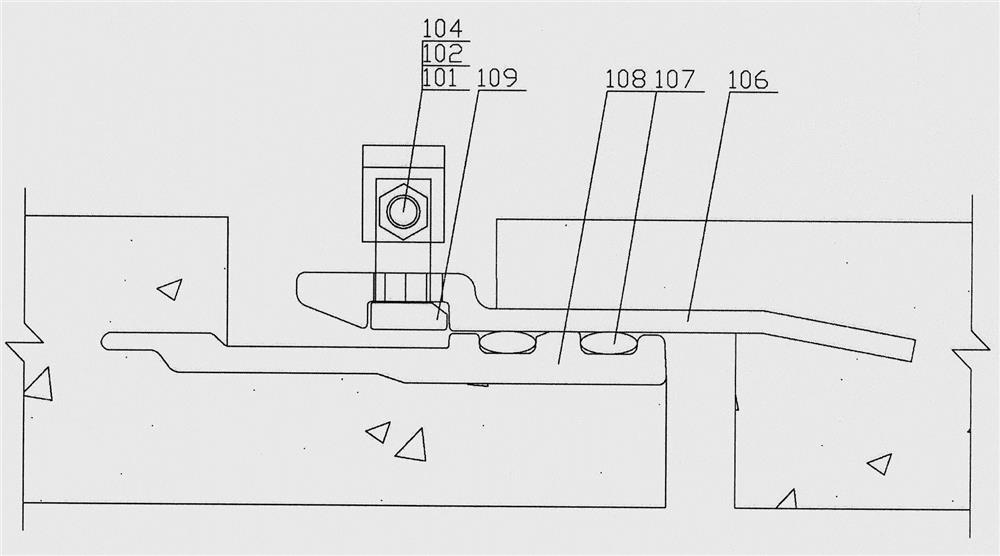

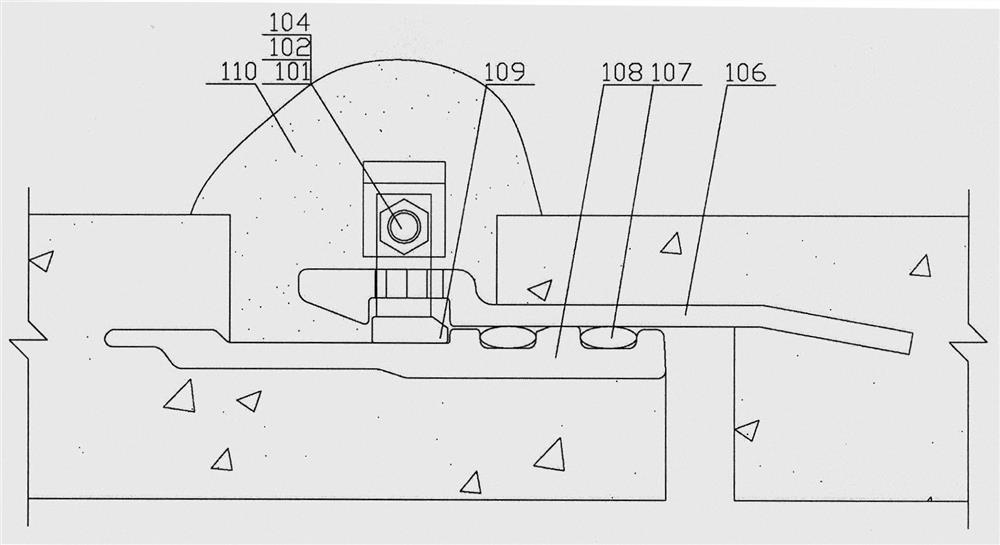

[0018] Such as figure 1 Shown, a kind of steel socket pipe restriction joint, comprises socket ring 106, opening snap ring 109, socket ring 108, screw rod 102, hex nut 101, U-shaped nut 104, rubber ring 107.

[0019] figure 2 The snap ring 109 is tightly attached to the groove of the socket ring 106; the socket ring 106 is provided with a rectangular hole 103 and a grouting hole 105; Ring; between the socket ring 106 and the socket ring 108, the compression rubber ring 107 is used to seal the joint.

[0020] image 3 Pass the screw 102 and the U-shaped nut 104 for the split snap ring 109, narrow the split snap ring 109 until the inner diameter of the split snap ring 109 is consistent with the outer diameter of the socket ring 108, and lock it with a hex nut 101; seal the pipe joint with mortar 110 , the flowing mortar flows into the gap between the snap ring 109 and the groove of the socket ring 106 through the grouting hole 105 provided on the socket ring 106 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com