Gear transmission encoder wheel set

A technology of gear transmission and encoder, which is applied in the direction of vibration suppression adjustment, spring/shock absorber, and the transmission of sensing components by mechanical devices, which can solve the problems of AGV walking accuracy reduction and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

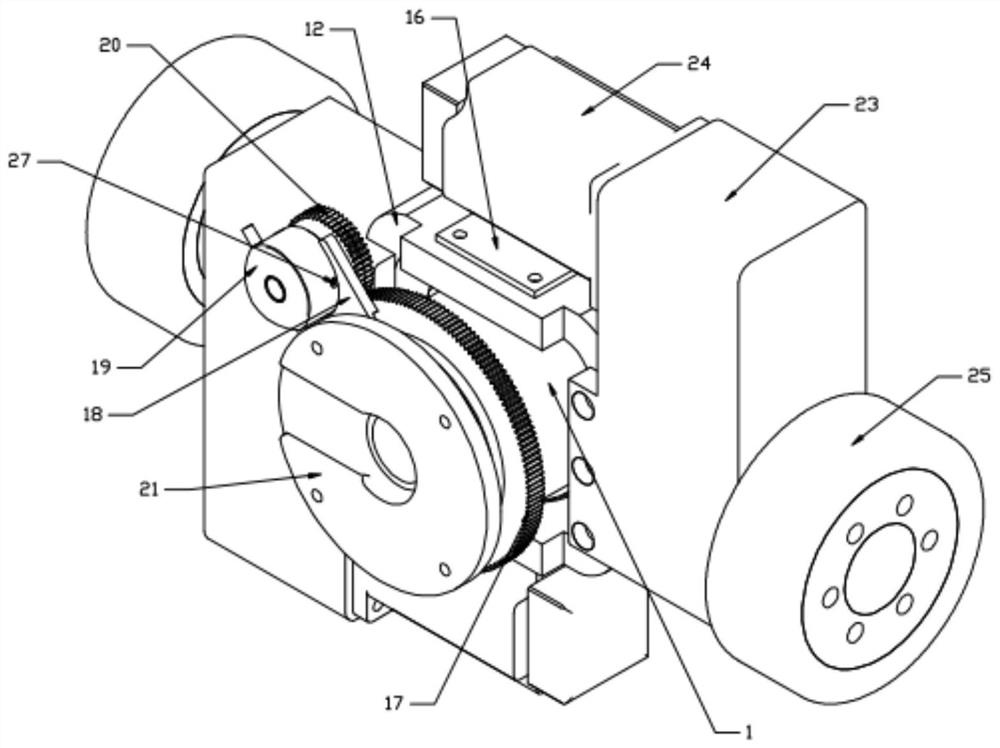

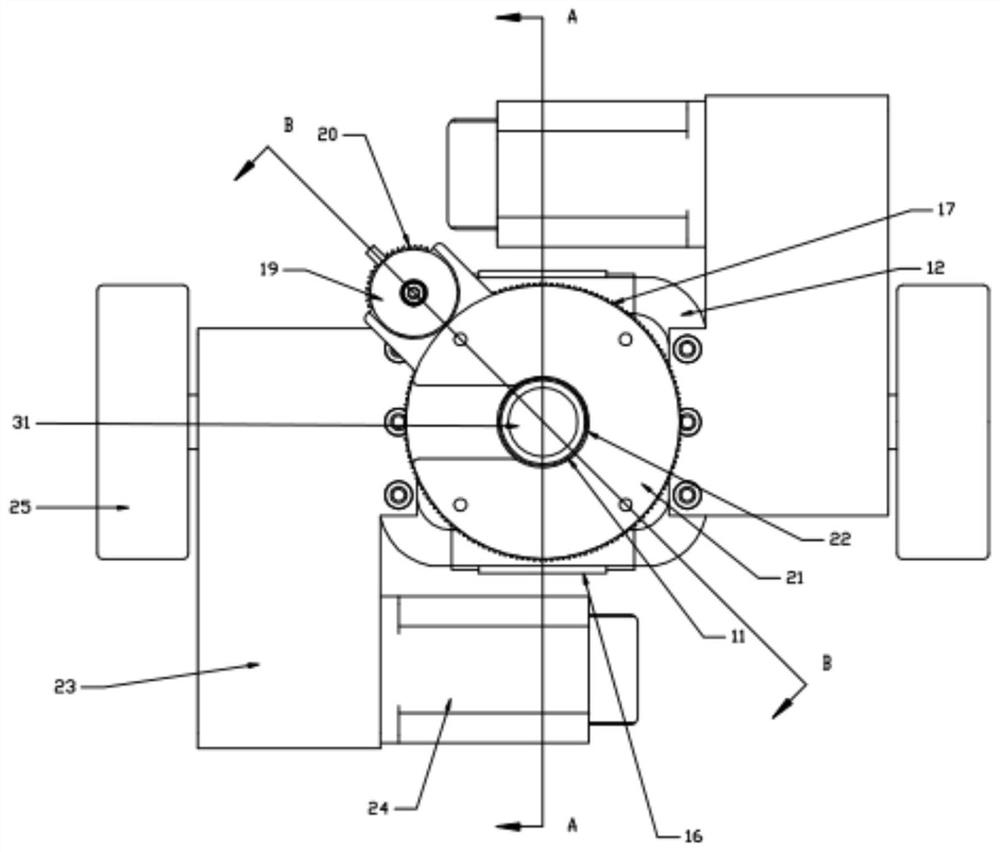

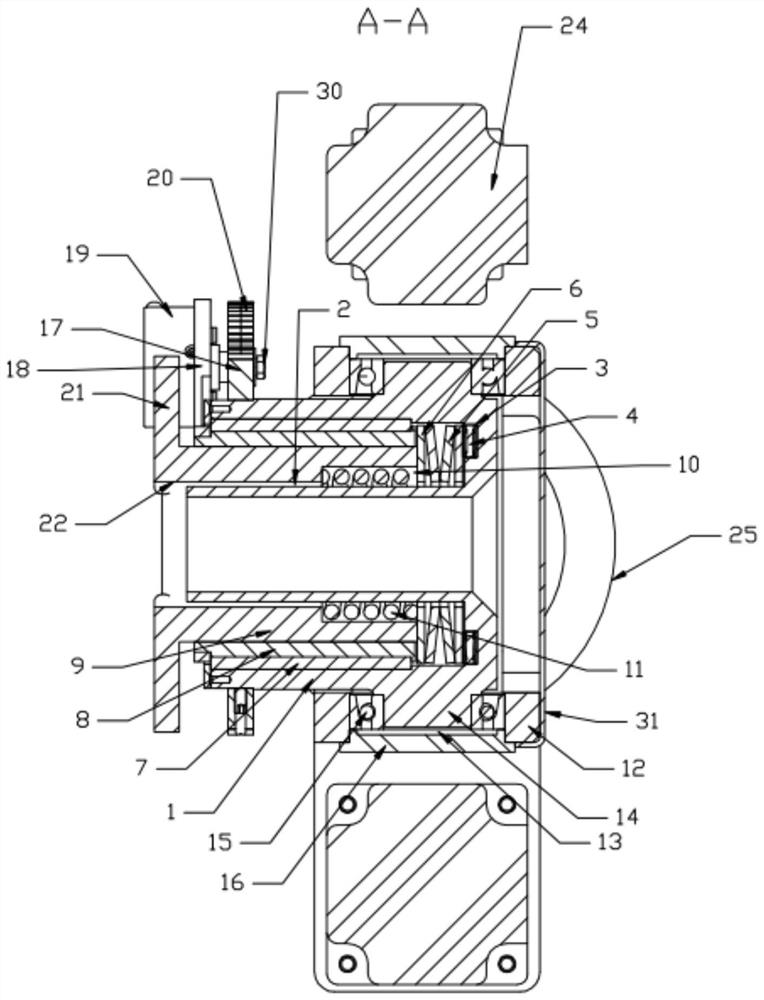

[0018] combined with figure 1 , figure 2 , image 3 , Figure 4 , a gear transmission encoder wheel set, including a lower cylinder 1, an annular groove 1 is provided on the upper surface of the lower cylinder 1, and an annular groove 2 3 is provided on the inner bottom surface of the annular groove 1 2, and an annular groove 2 3 is arranged on the inner bottom surface of the annular groove 2 3. A bearing 4 is provided, and the inner bottom surface of the annular groove 2 is provided with a disc spring 5 and a disc spring washer 6 sequentially from bottom to top. A shaft sleeve 7, a middle cylinder 8, and an upper cylinder 9 are provided. The upper cylinder 9 and the middle cylinder 8 are slidingly connected up and down. A spring 11 is provided in the circular gap 10, and a wheel frame 12 is sleeved on the lower end of the lower tube 1. Both sides of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap