Cement mortar splitting tensile test tool

A tensile test, cement mortar technology, used in measuring devices, using stable tension/pressure testing materials strength, instruments, etc. and other issues to avoid potential safety hazards and inaccurate calculations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below by specific embodiment in conjunction with accompanying drawing, but not as limiting the present invention.

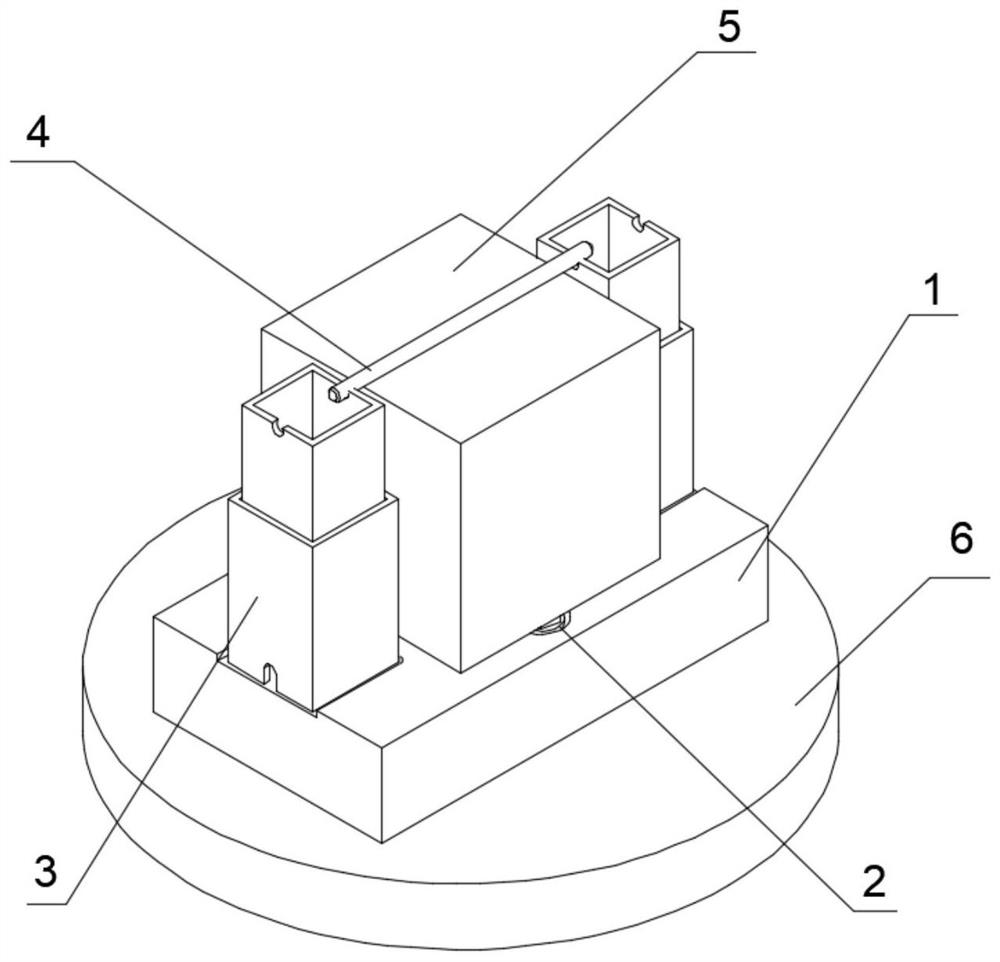

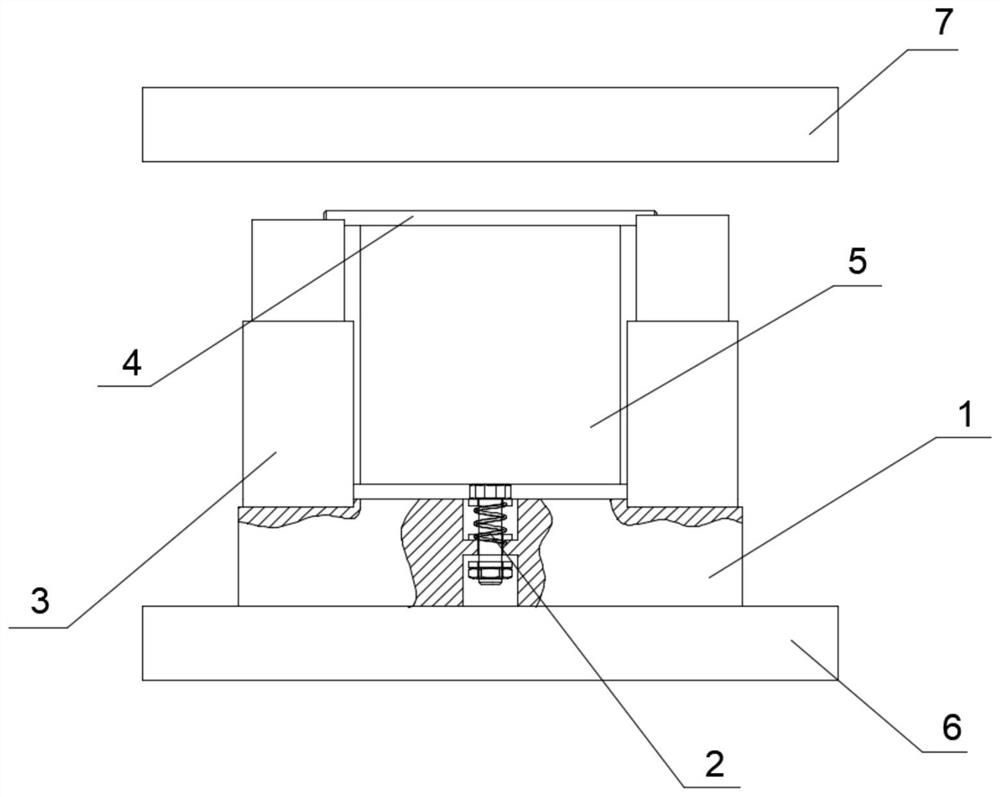

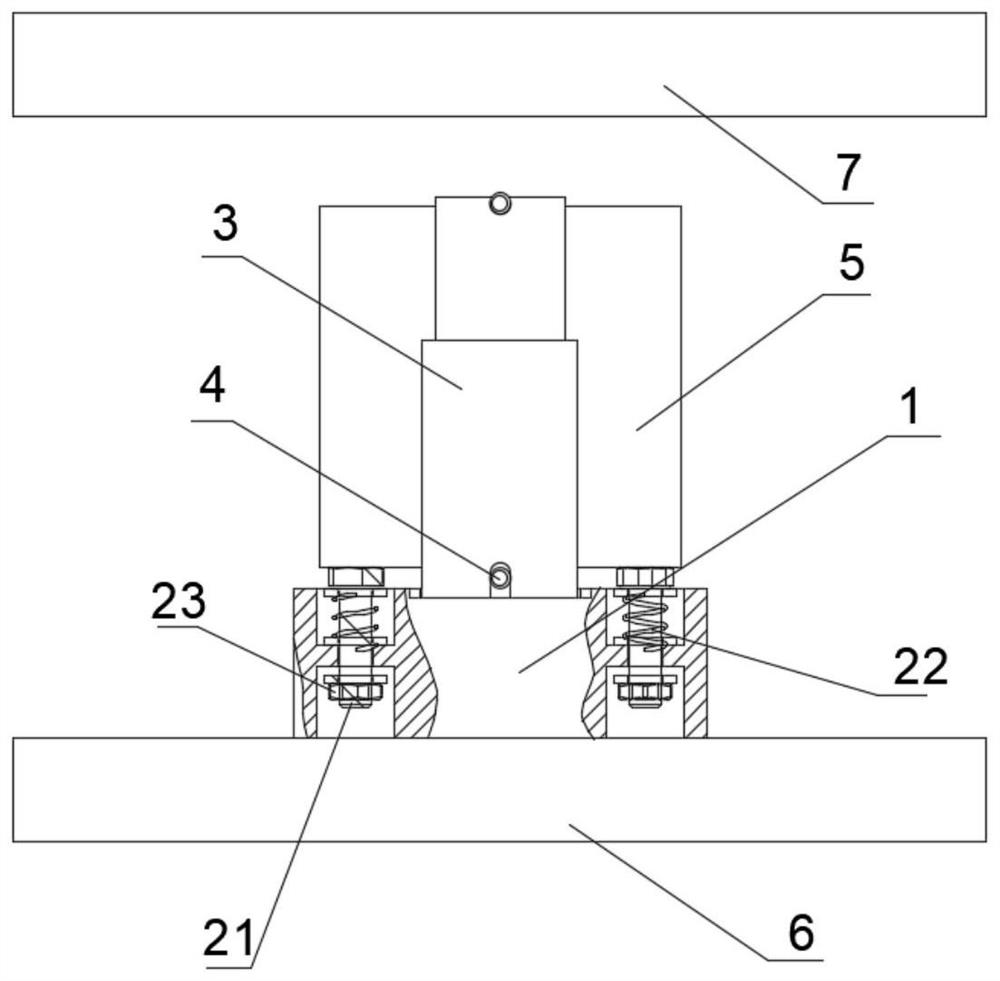

[0021] A cement mortar splitting tensile test tooling includes a base 1, a spring mechanism 2, and a sliding sleeve 3.

[0022] The base 1 is a cuboid structure, and the base 1 is provided with a sample position 11 , a base transverse groove 12 , and a stepped hole 13 . The sample position 11 is the area at the center of the upper surface of the base. Described base transverse groove 12 is two, and described base transverse groove 12 is positioned at the symmetrical position of sample position 11 both sides, and described base transverse groove 12 is opening structure near the side of base end. Described step hole 13 is two, and described step hole 13 is positioned at described sample position 11 internal two sides symmetry position, is circular hole, runs through base upper and lower surface.

[0023] Desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com