3D printing manicure model based on parametric design and construction method thereof

A parametric design and 3D printing technology, applied in the field of 3D printing and nail art, can solve the problems that 3D printing nail art technology has not been widely used, cannot prepare models in advance, and is difficult to establish or modify, so as to promote wide application, Conducive to rapid learning and mastery, great potential for promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

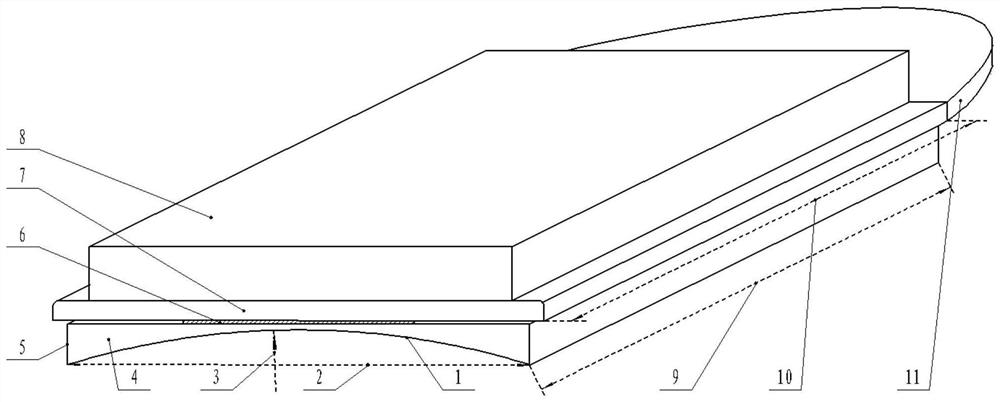

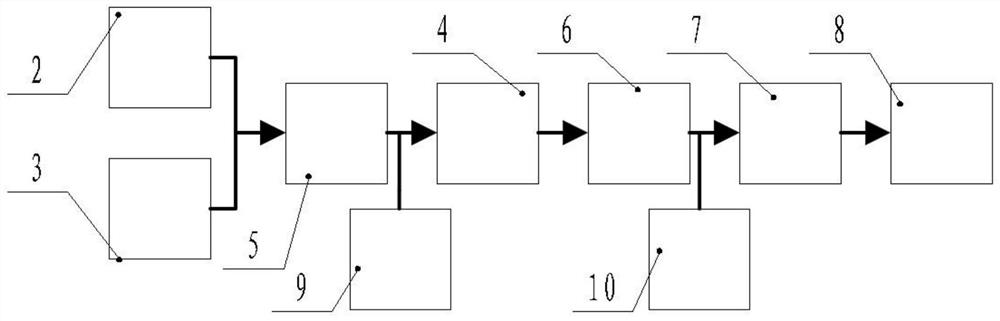

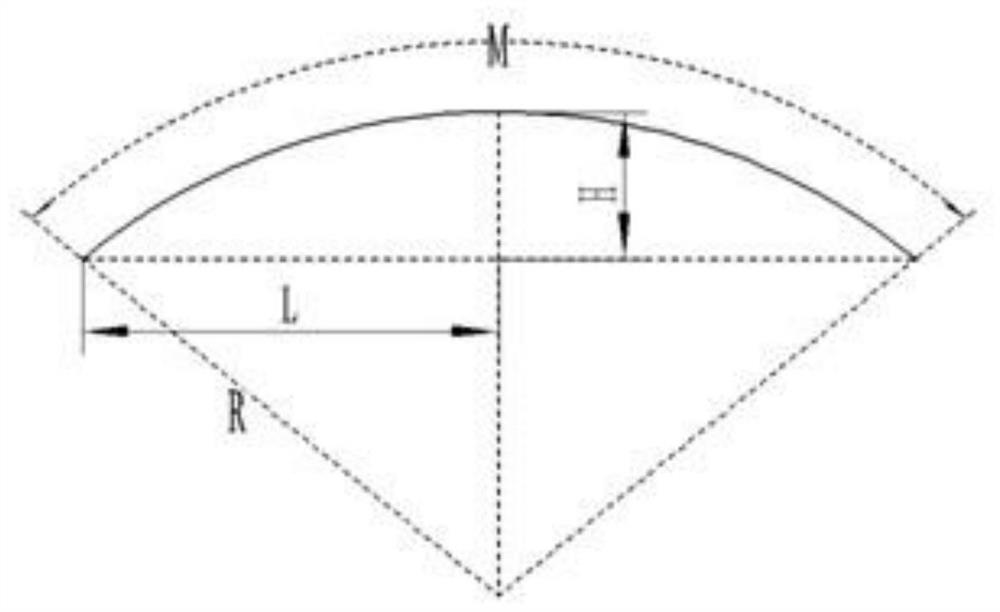

[0033] The present invention provides a 3D printing nail art model based on parametric design, as shown in Figure 1, including a bonding arc surface 1, arc surface chord length 2, arc surface radius 3, base 4, base thickness 5, connection Part 6, platform 7, three-dimensional decoration 8, base length 9, platform length 10, platform protrusion 11, wherein the main body of the model is the base 4, connecting part 6, platform 7 and three-dimensional decoration 8 from bottom to top, and they are mutually The whole model is formed by stacking, the bottom surface of the base 4 is the bonded arc surface 1; the model includes five main size parameters: the chord length of the arc surface 2, the radius of the arc surface 3, the thickness of the base 5, the length of the base 9 and the length of the platform 10, The control of these size parameters is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com