A Spindle Head Mechanism of In-situ Backfill Friction Stir Spot Welding

A friction stir and spindle head technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of friction spot welding joint mechanical properties, uneven heating of stirring tools, insufficient plastic flow, etc., to promote Wide application, flexible processing and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

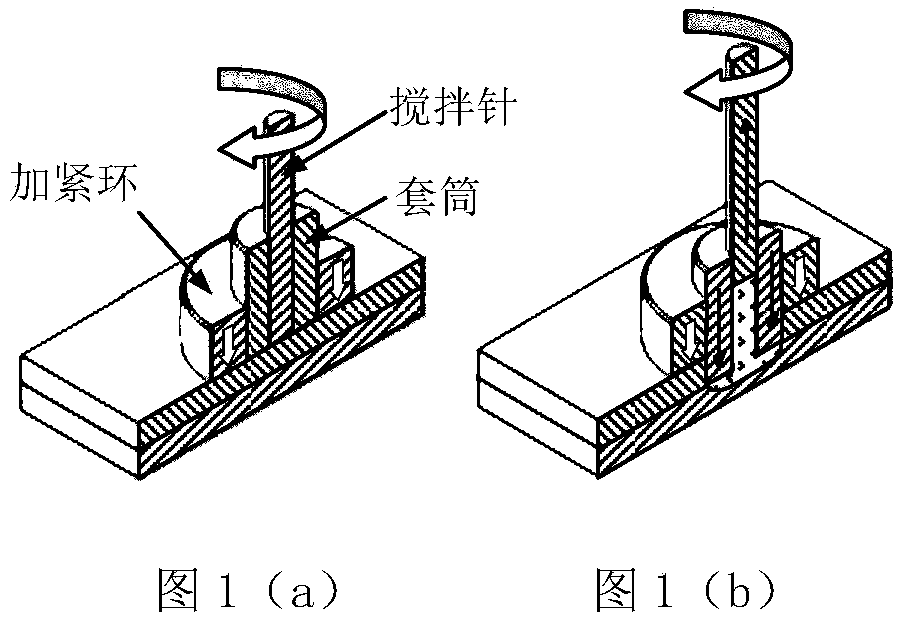

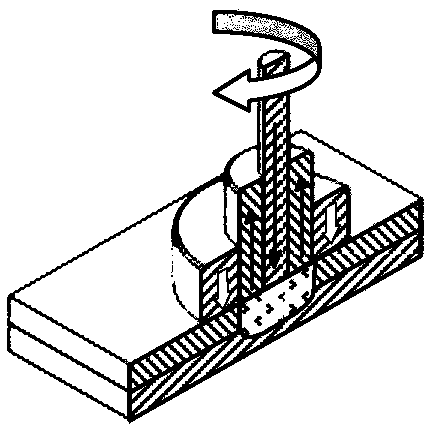

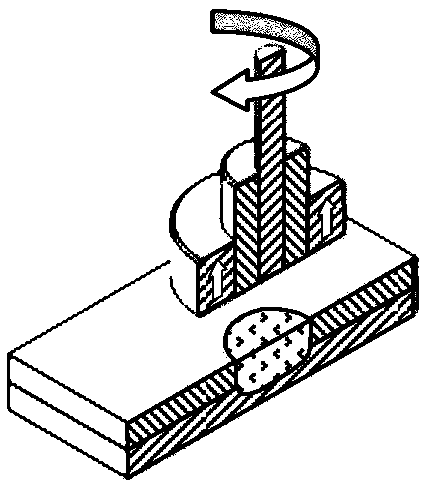

[0044] The design concept of the in-situ backfill friction stir spot welding spindle head mechanism proposed by the present invention is to propose a completely different spindle head motion control mechanism in the current RFSSW equipment in view of the limitations of the current RFSSW equipment spindle head mechanism. The spindle head mechanism adopts the hollow spindle nesting method, that is, the central shaft of the stirring needle is sleeved in the middle sleeve shaft, and the middle sleeve shaft is sleeved in the hollow shaft of the external clamping ring. Through the nesting method of three layers of hollow shafts, and then Use the servo motor to control the three-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com