Automatic testing method and system for smoke-sensing fire detector

An automated testing, smoke-sensing fire technology, applied in the direction of fire alarms, instruments, measuring devices that rely on the effect of smoke/gas, can solve the problems of manpower and time, low efficiency, etc., save manpower and time, improve The effect of inspection efficiency, shortening of waiting time and delivery cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

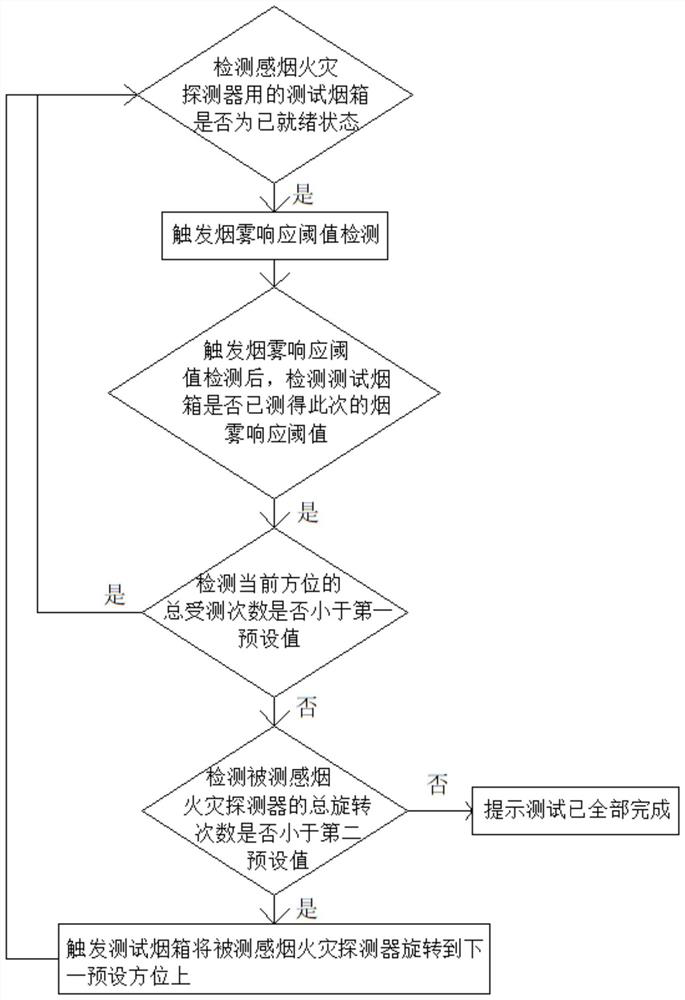

[0021] An embodiment of the present invention provides an automatic test method for a smoke detector, such as figure 1 shown, including the following steps:

[0022] Detect whether the test smoke box used for the smoke detector is in the ready state, and if so, trigger the smoke response threshold detection.

[0023] In this embodiment, in order to make the detection work more reliable, before triggering the smoke response threshold detection:

[0024] Test the smoke response threshold value measured by the first fire alarm controller reset of the smoke box;

[0025] After the smoke response threshold is cleared, the smoke box host of the test smoke box switches to the state to be triggered to detect the smoke response threshold.

[0026] In this embodiment, in order to avoid the situation that the flue is not cleaned in time, if the test smoke box is not in the ready state, the test smoke box is triggered to clean the flue.

[0027] In this embodiment, in order to realize ...

Embodiment 2

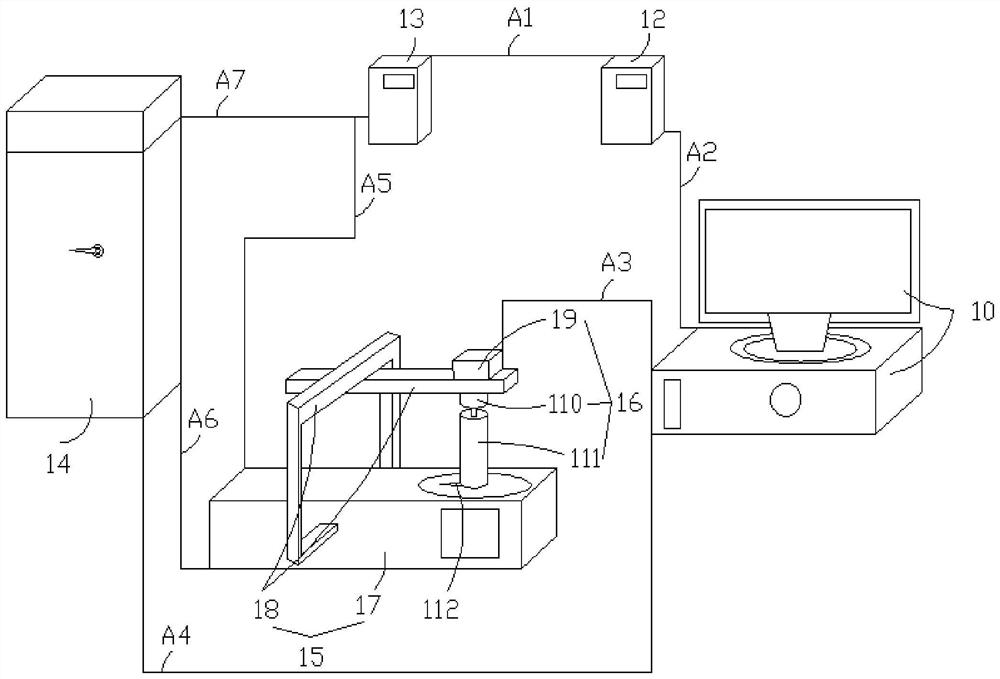

[0037] An embodiment of the present invention provides an automatic test system for a smoke detector, based on the automatic test method for a smoke detector provided in Embodiment 1, such as figure 2 shown, including:

[0038] Industrial control computer 10, and the test smoke box that smoke sense fire detector is used; The stepping motor driving assembly 16 that is rotated by the detected smoke fire detector in the box main body 15; the first fire alarm controller 12, the stepping motor driving assembly 16 and the smoke box host 14 are all electrically connected with the industrial control computer 10 and controlled by it. control; the smoke box main body 15 and the second fire alarm controller 13 are all communicated with the smoke box host 14; the first fire alarm controller 12 is connected with the second fire alarm controller 13; the second fire alarm controller 13 is connected with the Smoke box main body 15 communication connection;

[0039] The industrial control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com