Pole piece, preparation method of pole piece and battery

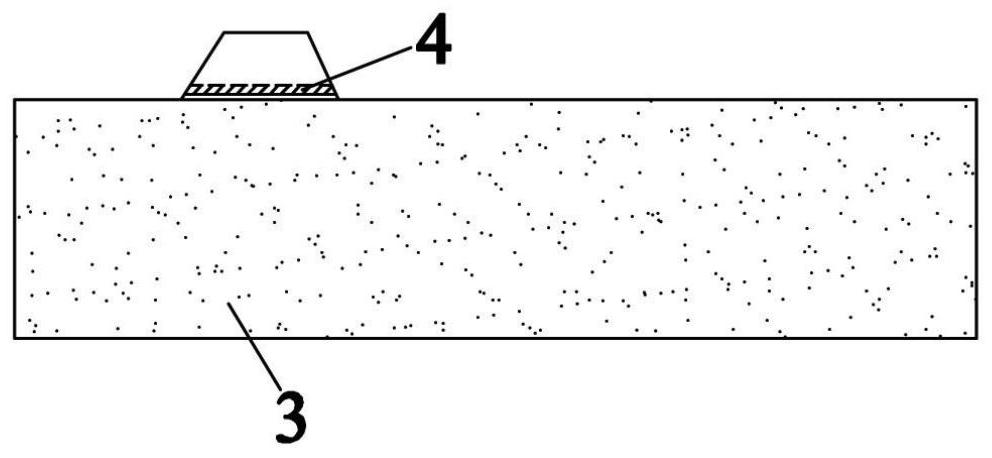

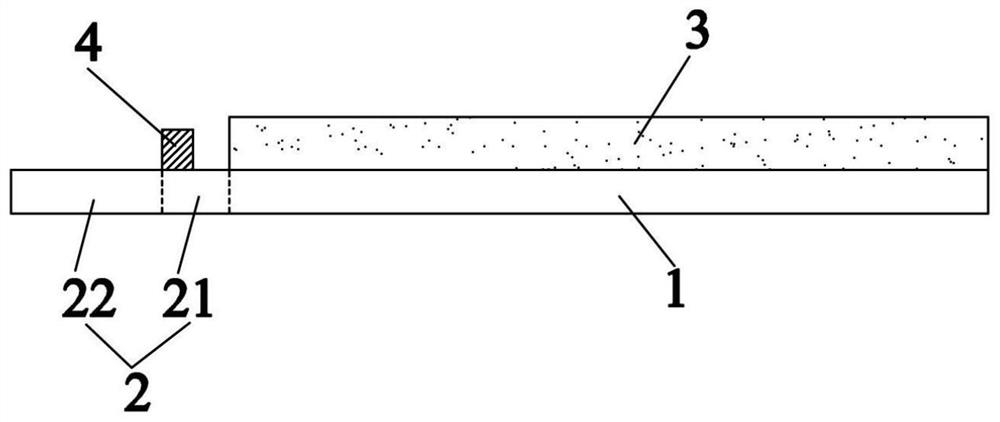

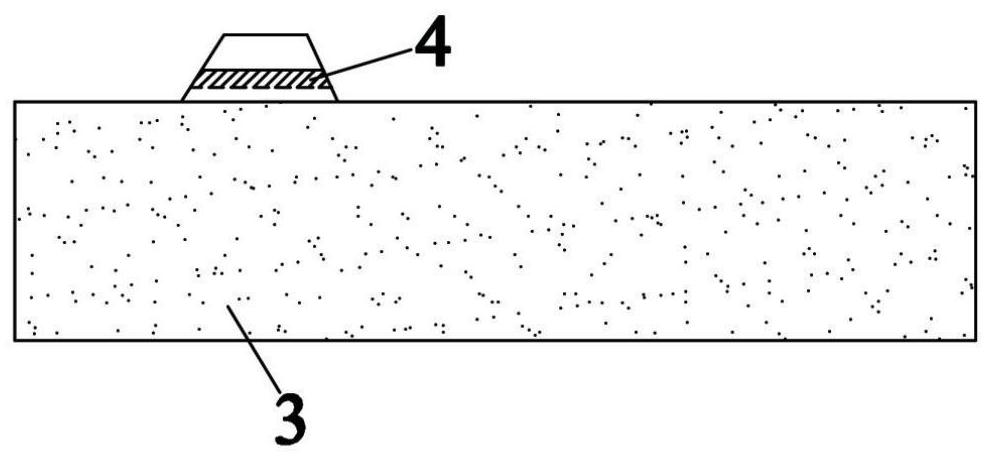

A technology of pole pieces and tabs, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of easy folding of thin substrates, hidden dangers of battery safety, and folding of tabs, so that it is not easy to fold and improve energy density , reduce the effect of stepping edge angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] 2. The second aspect of the present application provides a method for preparing the pole piece described in the present application, comprising the steps of:

[0049] Take a current collector, the current collector includes a pole piece body area and a tab area, and the tab area includes a connection area and a tab body area, and the tab body area is connected to the pole piece body through the connection area zone connection;

[0050] preparing an active material slurry, coating it on at least one surface of the pole piece main body area, and drying to form an active material layer;

[0051] Prepare a protective coating slurry, apply it on at least one surface of the tab area, and dry to form a protective coating, the protective coating at least partially coats the connection area and / or the tab main body Area;

[0052] Die-cutting the tab area of the current collector to obtain a pole piece main body and a pole piece connected to the pole piece main body.

[0053...

Embodiment 1~6 and comparative example 1

[0076]Carry out the preparation of pole piece according to the following method:

[0077] 1) Preparation of cathode active material slurry:

[0078] Mix the lithium nickel manganese cobalt ternary material (NCM523), the conductive agent SuperP, and the binder polyvinylidene fluoride according to the weight ratio of 97:1.4:1.6, add N-methylpyrrolidone (NMP), under the action of a vacuum mixer Stir until the system is uniform, and obtain a positive electrode active material slurry with a solid content of 72%.

[0079] 2) Preparation of protective coating slurry:

[0080] Dissolve each component (see Table 1 for details) in a solvent, first stir at a rotation speed of 1400rpm and a revolution speed of 25rpm for 3h, and scrape the glue once every 1h during the stirring period; then use a rotation speed of 0rpm and a revolution speed of 10rpm Slowly stir and defoam in vacuum for 1 hour to obtain a protective coating slurry with a solid content of 10-80% and a viscosity of 1000-10...

Embodiment 7~12 and comparative example 2

[0087] Carry out the preparation of pole piece according to the following method:

[0088] 1) Preparation of negative electrode active material slurry:

[0089] Negative electrode active material artificial graphite, conductive agent SuperP, thickener sodium carboxymethylcellulose (CMC), binder styrene-butadiene rubber (SBR) are mixed according to the weight ratio of 96.4:1.5:0.5:1.6, and deionized water is added , under the action of a vacuum mixer, a negative electrode active material slurry with a solid content of 54% was obtained.

[0090] 2) Preparation of protective coating slurry:

[0091] Dissolve each component (see Table 1 for details) in a solvent, first stir at a rotation speed of 1400rpm and a revolution speed of 25rpm for 3h, and scrape the glue once every 1h during the stirring period; then use a rotation speed of 0rpm and a revolution speed of 10rpm Slowly stir and defoam in vacuum for 1 hour to obtain a protective coating slurry with a solid content of 10-80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com