Water boiler

A water boiler and case technology, which is applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve the problem of ineffective heat exchange between the cold water tank and the heat exchange tube, the rapid rise of the water temperature in the cold water tank, and the inability of the heat exchange tube to be fast Cooling and other issues, to achieve the effect of reasonable layout, prolonging the time of continuous cooling, and slowing down the speed of water temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

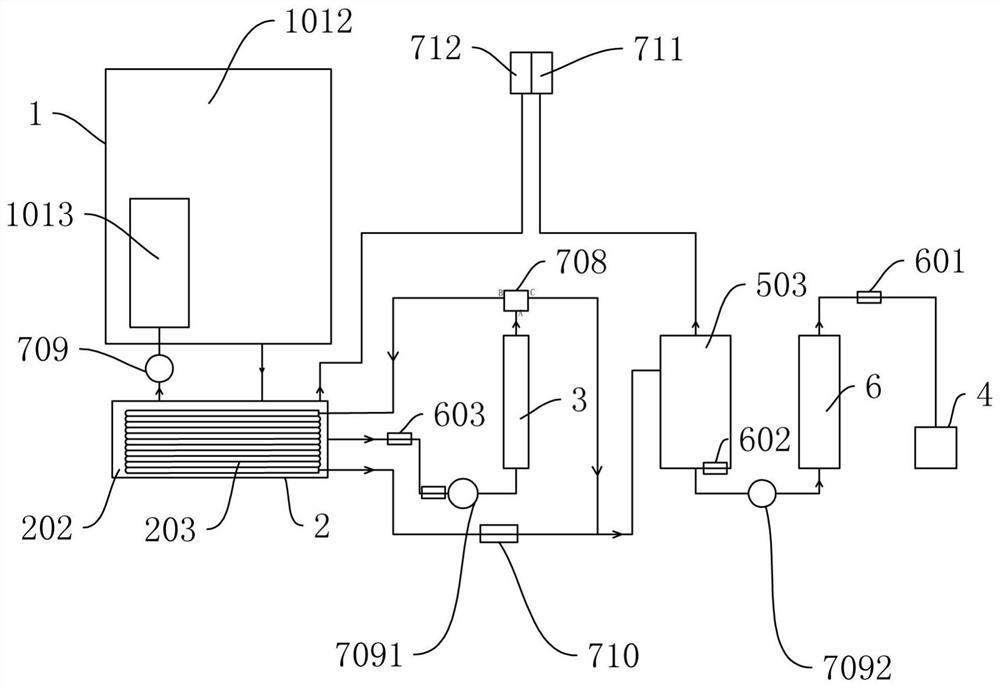

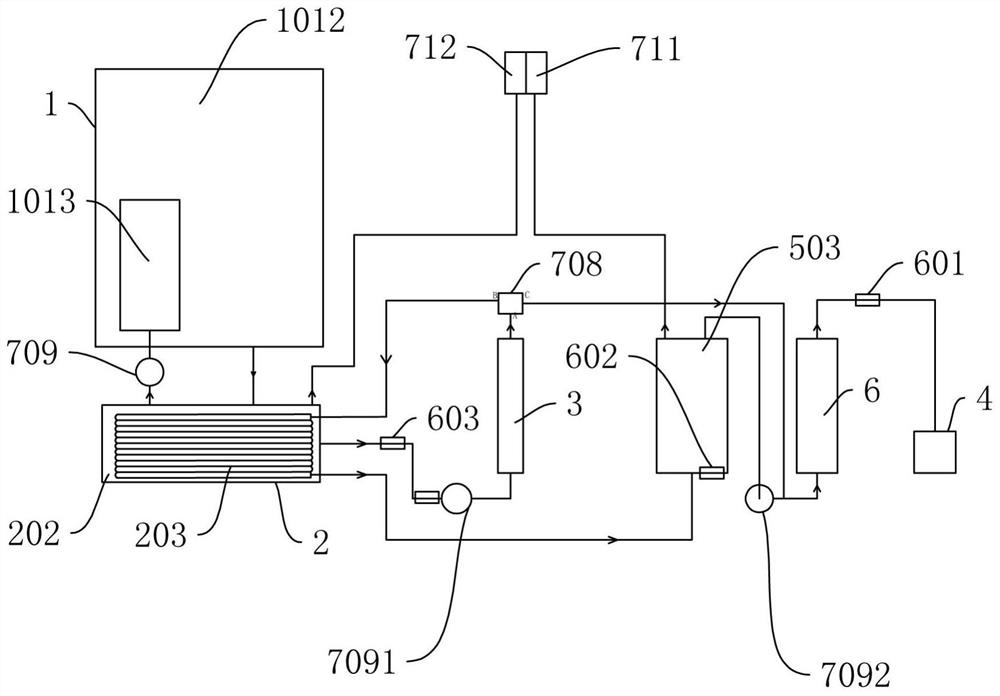

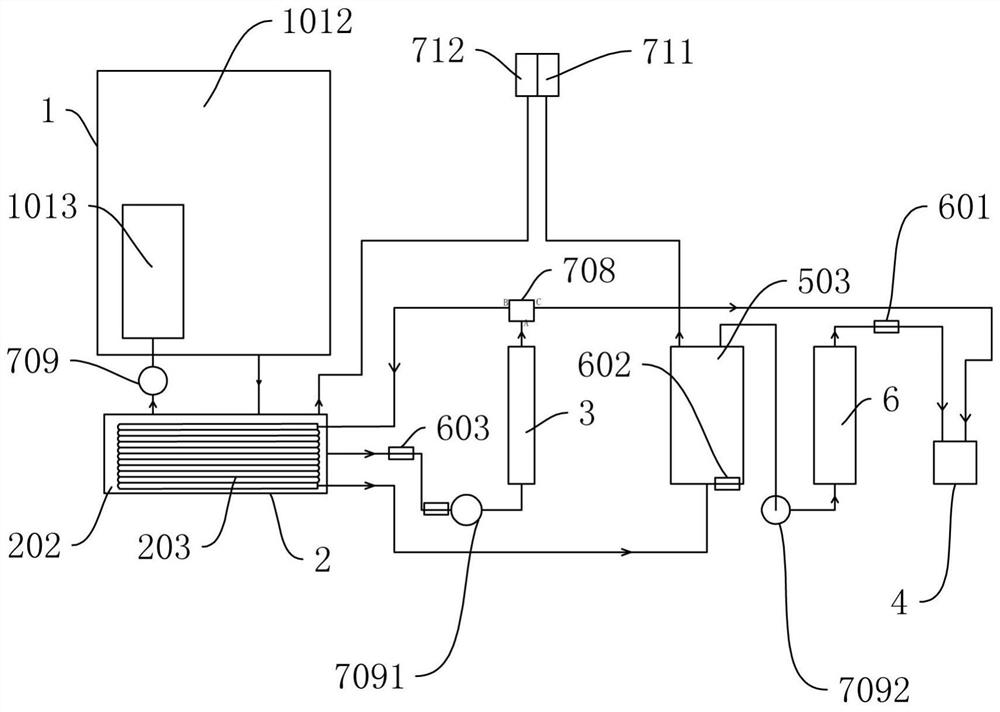

[0036] Such as Figure 1 to Figure 12 shown

[0037]A water boiling machine, comprising a chassis 707, and a water tank 1 located inside the chassis 707, a cooling chamber 2, a primary heating device 3, a water chamber 503, and a secondary heating device 6, the water tank 1 is detachably connected to the chassis 707, and the cooling chamber 2. Located below the water tank 1 and fixedly connected to the bottom of the cabinet 707. The water tank 1 is provided with an inner tank 11. The water tank 1 includes an outer chamber 1012 located outside the inner tank 11 and an inner chamber 1013 located in the inner tank 11. The outer chamber 1012 is connected to the inner tank 11. The chamber 1013 communicates, the bottom of the water tank 1 is provided with a first water outlet 10121 communicated with the outer chamber 1012, and a first water inlet 10131 communicated with the inner chamber 1013, and the cooling chamber 2 is provided with a cooling pipe 203 fixedly connected thereto, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com