Multi-angle drilling device and multi-angle drilling method for auto spare parts manufacturing

A technology for auto parts and drilling equipment, which is applied in the direction of drilling/drilling equipment, manufacturing tools, boring/drilling, etc., and can solve the problems of reducing the working efficiency of multi-angle drilling operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

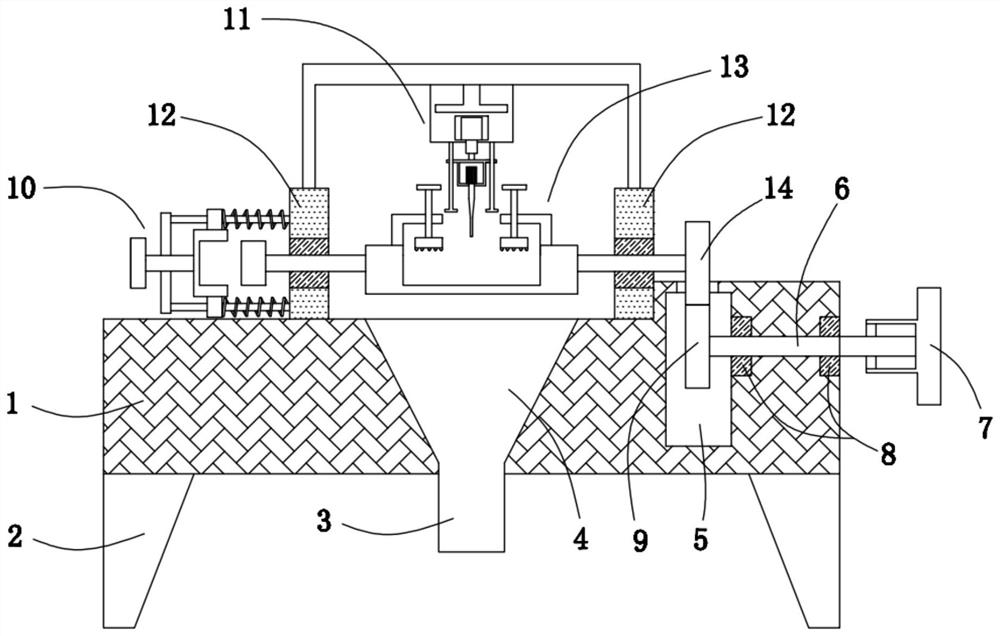

[0025] The present invention provides such Figure 1-4 A kind of multi-angle drilling equipment for auto parts manufacturing, including a workbench 1, brackets 12 are provided on both sides of the upper end of the workbench 1, and a clamping mechanism 13 is connected between the two sets of brackets 12, and the left side The bracket 12 is connected with a braking mechanism 10, and the upper ends of the two groups of brackets 12 are also connected with a drilling mechanism 11;

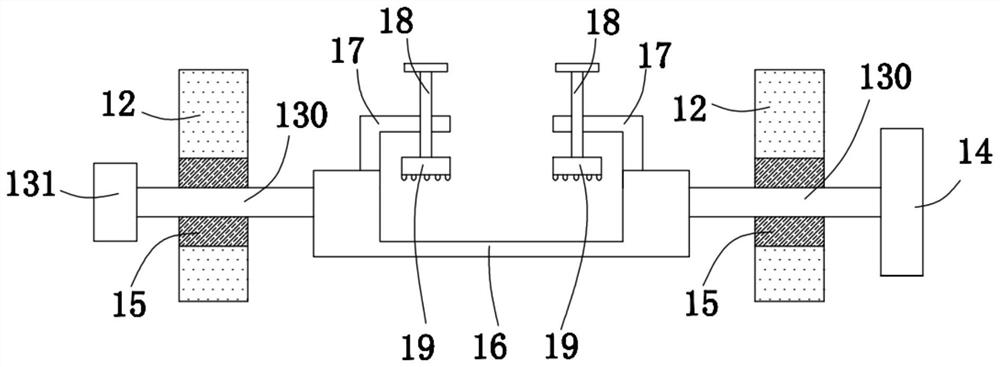

[0026] The clamping mechanism 13 includes the first bearing 15 inside the bracket 12, the rotating shaft 130 penetrating through the first bearing 15, the clamping seat 16 connected between the two sets of rotating shafts 130, and the L-shaped frame at the upper ends of the clamping seat 16. 17. The L-shaped frame 17 is screwed with a T-bolt 18 and a chuck 19 connected to the lower end of the T-bolt 18;

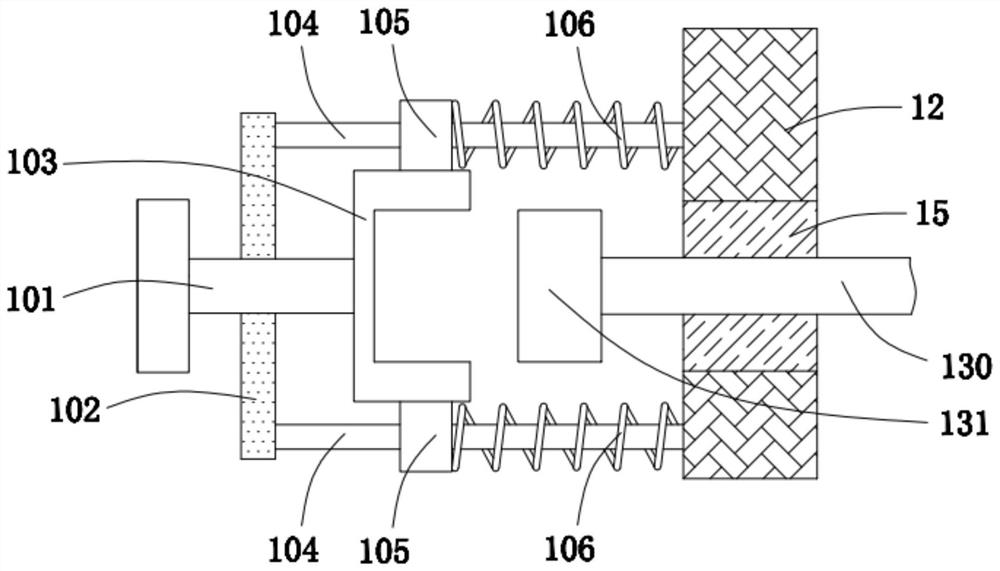

[0027] The left end of the rotating shaft 130 on the left side is connected with a friction disc 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com