Laser visualization processing method and system

A processing method and processing system technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to directly observe products, and achieve the effect of easy adjustment and improved verification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

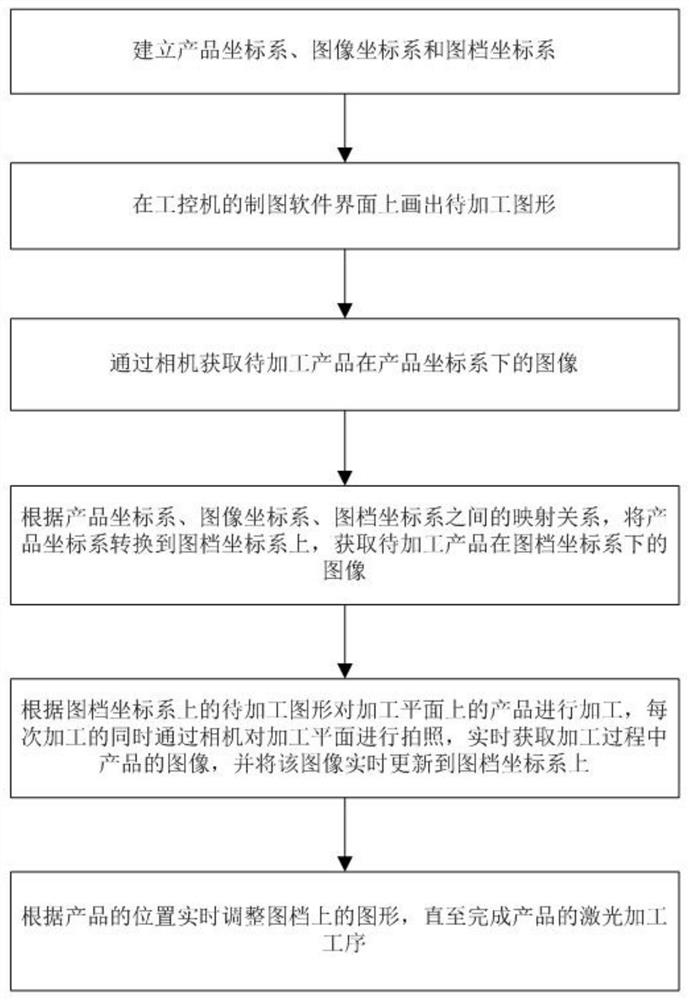

[0057] Such as figure 1 As shown, the present embodiment provides a laser visualization processing method, comprising the following steps:

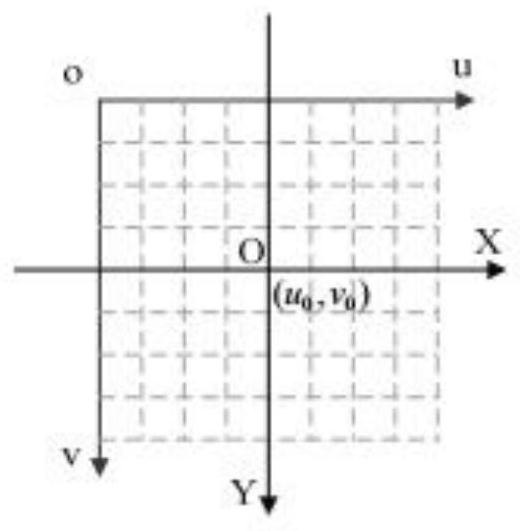

[0058] Establish product coordinate system, image coordinate system and picture file coordinate system respectively; Described product coordinate system is positioned on processing plane; Described image coordinate system is positioned at the image surface of camera; Described picture file coordinate system is positioned at the drawing software interface of industrial computer superior;

[0059] Draw the graphics to be processed on the drawing software interface of the industrial computer;

[0060] Obtain the image of the product to be processed in the product coordinate system through the camera;

[0061] According to the mapping relationship between the product coordinate system, the image coordinate system and the drawing coordinate system, the product coordinate system is converted to the drawing coordinate system, and the image of ...

Embodiment 2

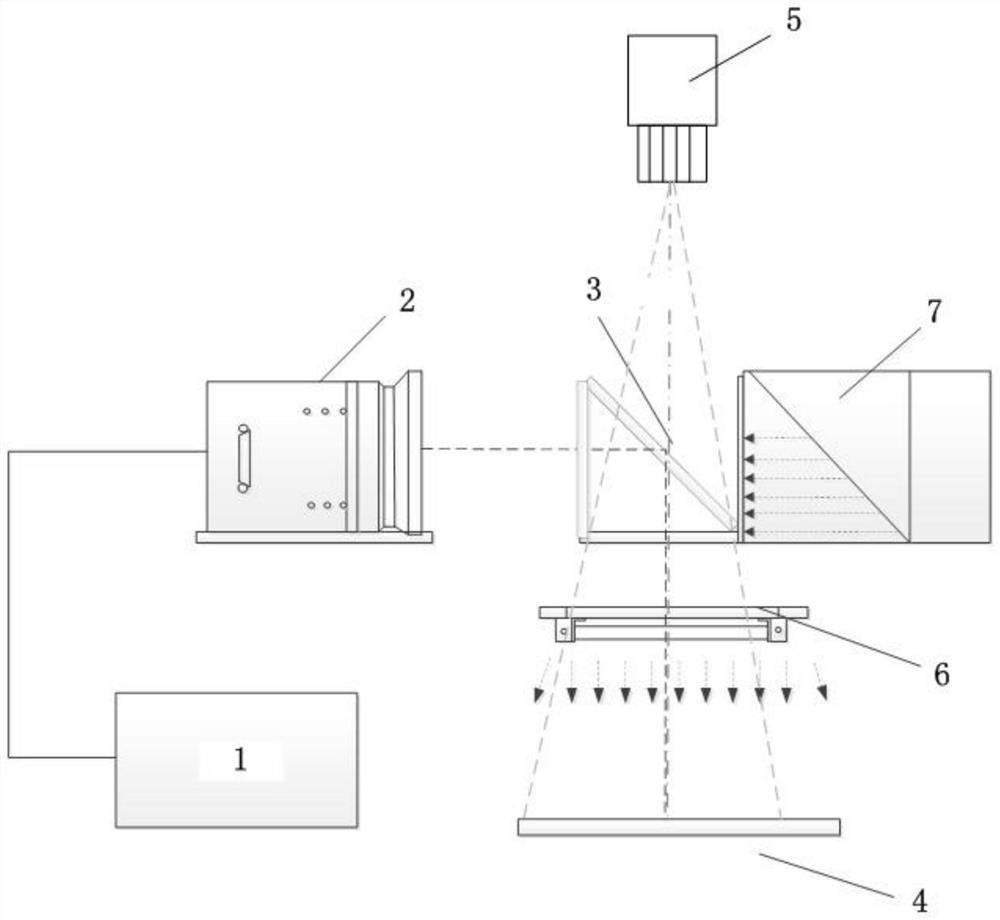

[0098] Such as figure 2 As shown, this embodiment provides a laser visualization processing system, including a laser 1, a galvanometer 2, a refractor 3 and a processing plane 4 arranged sequentially along the laser processing optical path; a camera 5 is arranged above the refractor 3; The processing plane 4 is arranged below the refractor 3, and an illuminating device is arranged between the processing plane 4 and the refracting mirror 3, and the illuminating device provides an illumination source for the processing plane 4; One side; the laser light emitted by the laser device 1 passes through the vibrating mirror 2 and the refracting mirror 3 to reach the processing plane 4 in turn, and the product is processed; the camera 5 acquires the image of the product on the processing plane 4 in real time, and the acquired image is real-time Update to the drawing file on the drawing software interface of the industrial control machine.

[0099] Specifically, the refractor 3 is a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com