Auxiliary tool for automatic welding of automobile beam

An automatic welding and auxiliary tooling technology, applied in welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve the problems of small moving range, inconvenient manufacturing and use, lack of integration, etc., to achieve easy clamping and welding, To achieve the effect of precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

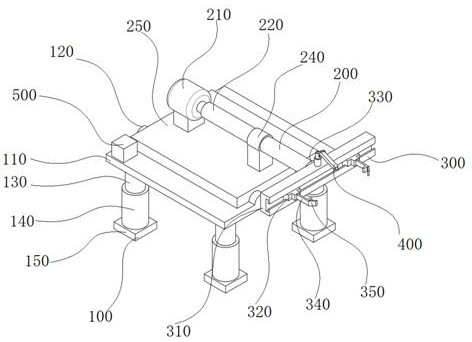

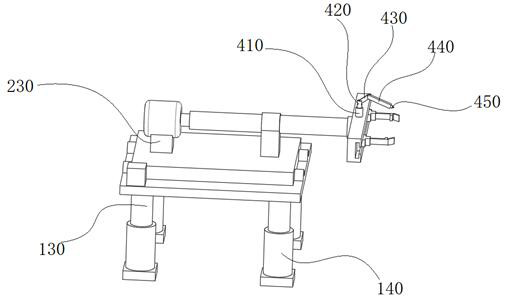

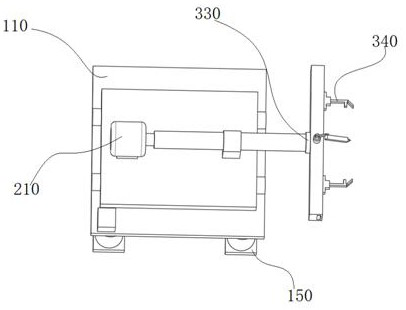

[0020] Please refer to figure 1 -As shown in -4, an auxiliary tooling for automatic welding of an automobile girder includes a support device 100, a rotating device 200, a clamping device 300, a welding device 400, and an integrated controller 500, and the support device 100 includes a base plate 110 and a fixed slideway 120 The rotating device 200 includes a rotating shaft 220 and an electric skateboard 250, and several fixed slideways 120 are slidingly fitted with the electric sliding board 250. The clamping device 300 includes a cross bar 310 and a rotating disc 330, and one end of the rotating shaft 220 rotates with the rotating disc 330. In cooperation, the welding device 400 includes a fixed round tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com