Drilling mechanism for manufacturing wood and bamboo products

A technology for drilling mechanism and bamboo products, which is applied in manufacturing tools, stationary drilling machines, wood processing appliances, etc., can solve the problems of scattered impurities, physical harm to employees in the factory, and diffuse dust-level particles, and can reduce the content of dust, The effect of reducing hazards and avoiding positional displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

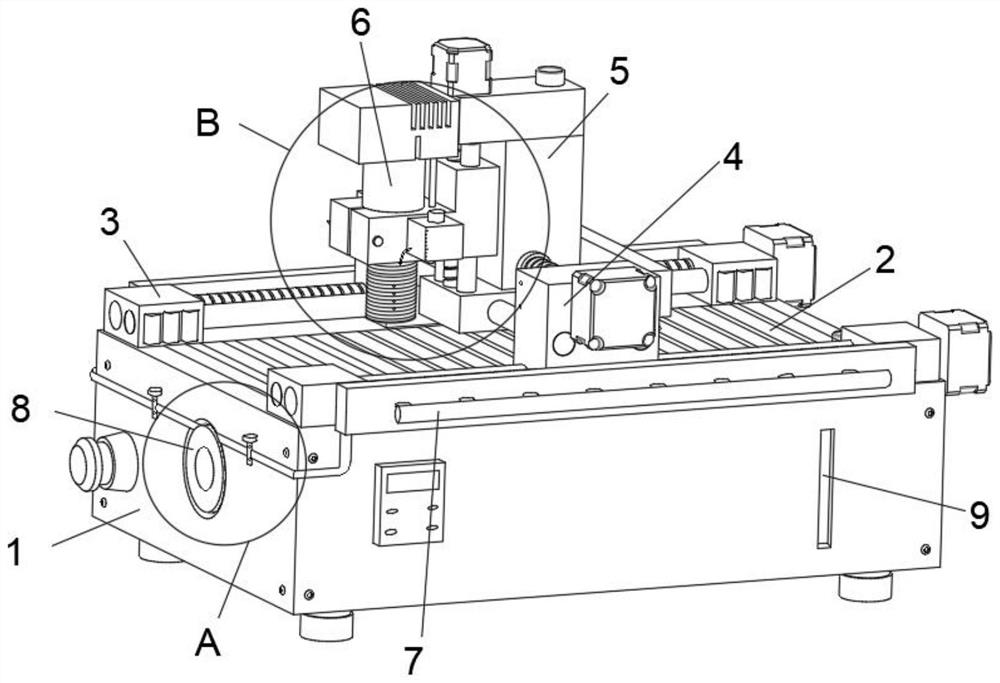

[0026] The following is attached figure 1 To further illustrate the specific implementation of a drilling mechanism for manufacturing wood and bamboo products of the present invention. The drilling mechanism for manufacturing wood and bamboo products of the present invention is not limited to the description of the following embodiments.

[0027] This embodiment provides a specific structure of a drilling mechanism for manufacturing wood and bamboo products, such as Figure 1-4 As shown, a drilling mechanism for manufacturing wood and bamboo products includes:

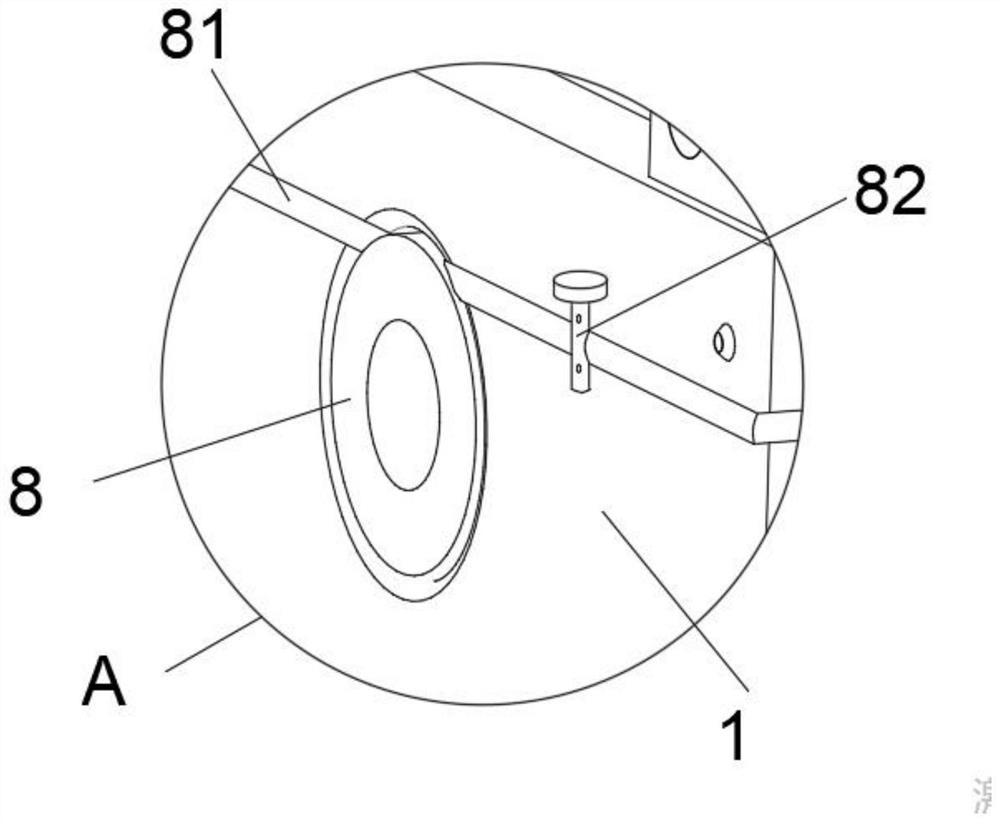

[0028] Machine base 1, on which a number of rollers 2 for conveying materials are installed;

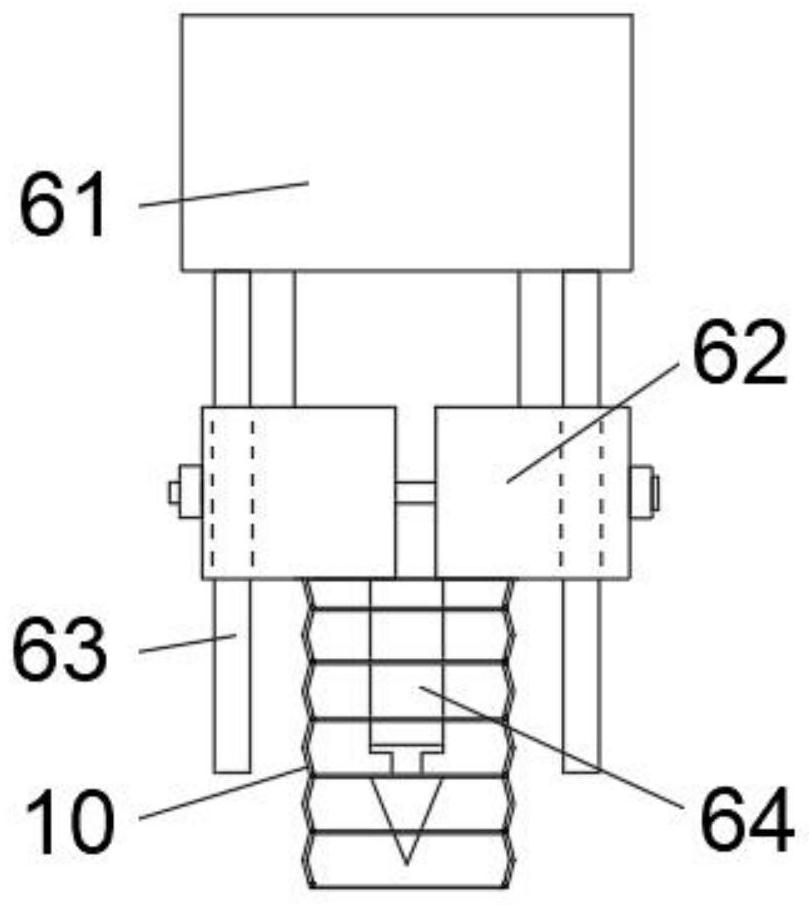

[0029] The adjustment assembly includes an X-axis mechanism 3, a Y-axis mechanism 4, and a Z-axis mechanism 5. The X-axis mechanism 3 is used to drive the Y-axis mechanism 4 to move linearly on the X-axis, and the Y-axis mechanism 4 is used to drive the Z-axis mechanism 5. Performing linear movement on the Y axis, a drilling assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com