Ho<3+> doped ZBYA fluoride glass

A fluoride and glass technology, used in glass forming, glass pressing, glass manufacturing equipment, etc., can solve the problem of inability to transmit mid-infrared lasers over long distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

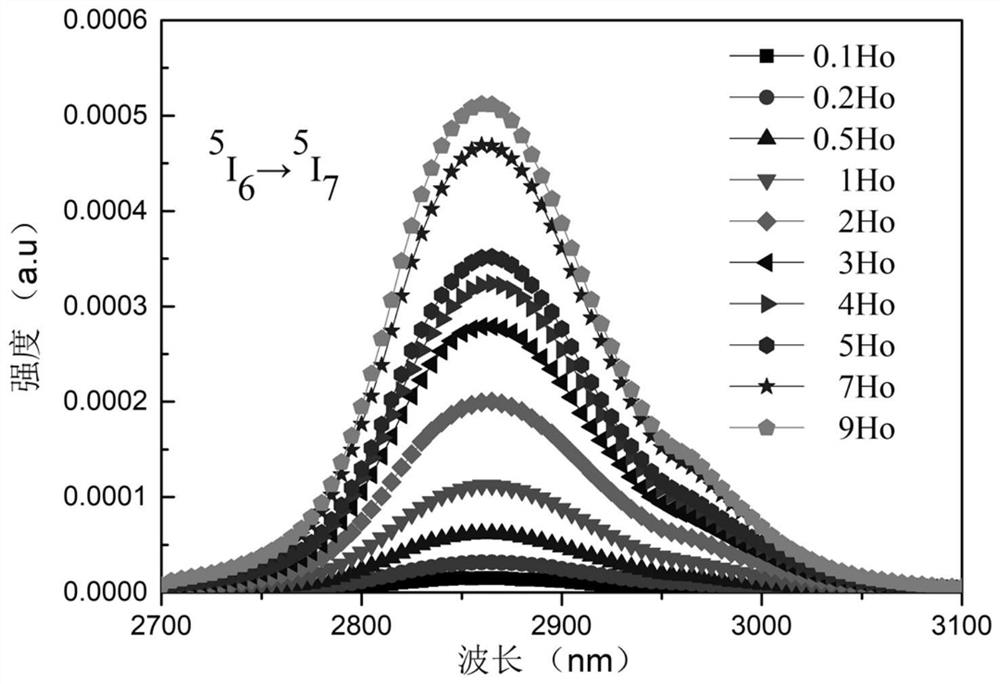

[0019] A Ho 3+ Doped ZBYA fluoride glass that can produce fluorescence in the mid-infrared band near 3.9 μm, including the following:

[0020] Ho 3+ Preparation of ion-doped ZBYA fluoride glass:

[0021] Weigh the high-purity raw materials according to the following mole percentages, and mix them thoroughly in the grinding bowl;

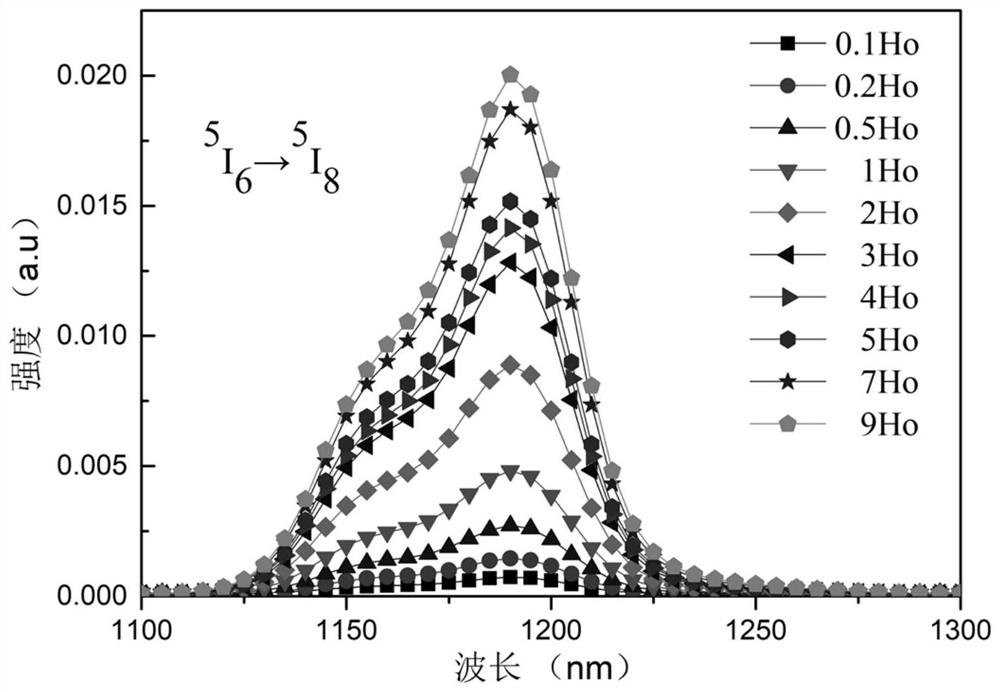

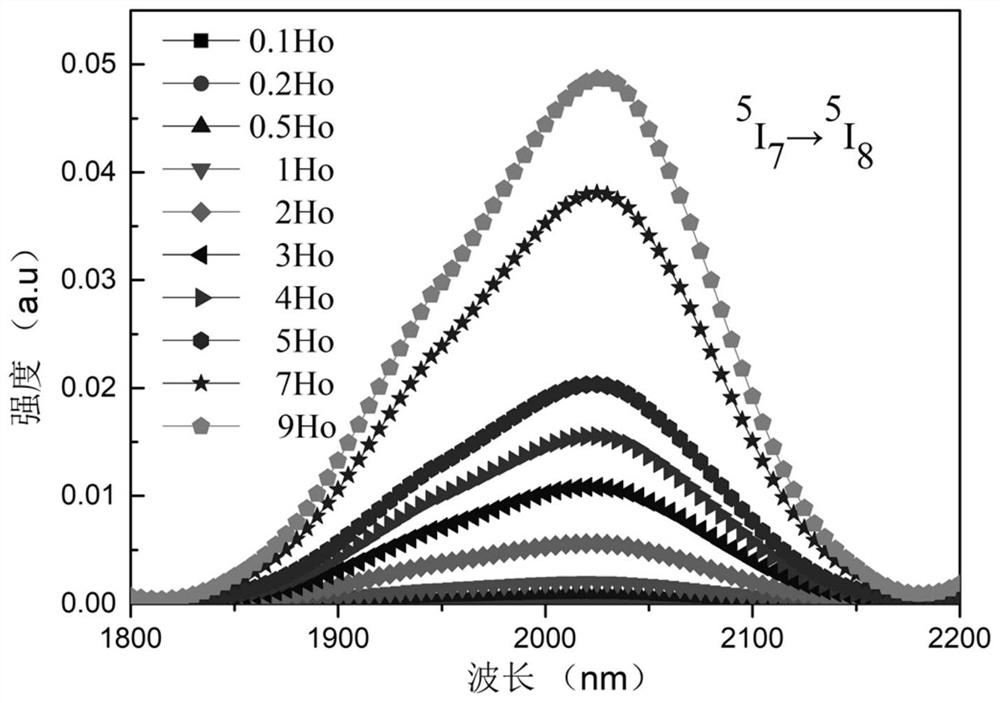

[0022] 50ZrF 4 –49-x (BaF 2 –YF 3 –AlF 3 )–xHoF 3 (x=0.1,0.2,0.5,1,2,3,4,5,7,9)

[0023] glass melting

[0024] Put the mixture in a platinum crucible with a lid, melt it in a high-temperature furnace in a glove box at 850°C, then place the molten glass on a preheated brass mold, and place it in an annealing furnace for annealing at 320°C to eliminate the glass The stress generated in the process to obtain the final glass sample.

[0025] glass polishing

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com