Ho<3+>-doped fluorine-aluminum glass

A glass, fluorine aluminum technology, applied in glass production and other directions, can solve the problems of limiting the application prospect of fluoride glass, moisture absorption, crystallization, etc., and achieve the effects of excellent chemical stability, high transparency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] 1. Weigh the high-purity raw materials according to the following molar percentages, and mix them thoroughly in the grinding bowl; 1,1.5,2,3,4,6,8,10)

[0027] 2. Put the mixture in a platinum crucible with a lid, melt it in a glove box high-temperature furnace at 930°C, then place the molten glass on a preheated brass mold, and place it in an annealing furnace at 270°C for annealing. Relieve the stress generated in the glass to obtain the final glass sample.

[0028] 3. Cut the prepared glass sample according to the size of 10mm*10mm*2mm, and finely polish both sides for testing at room temperature.

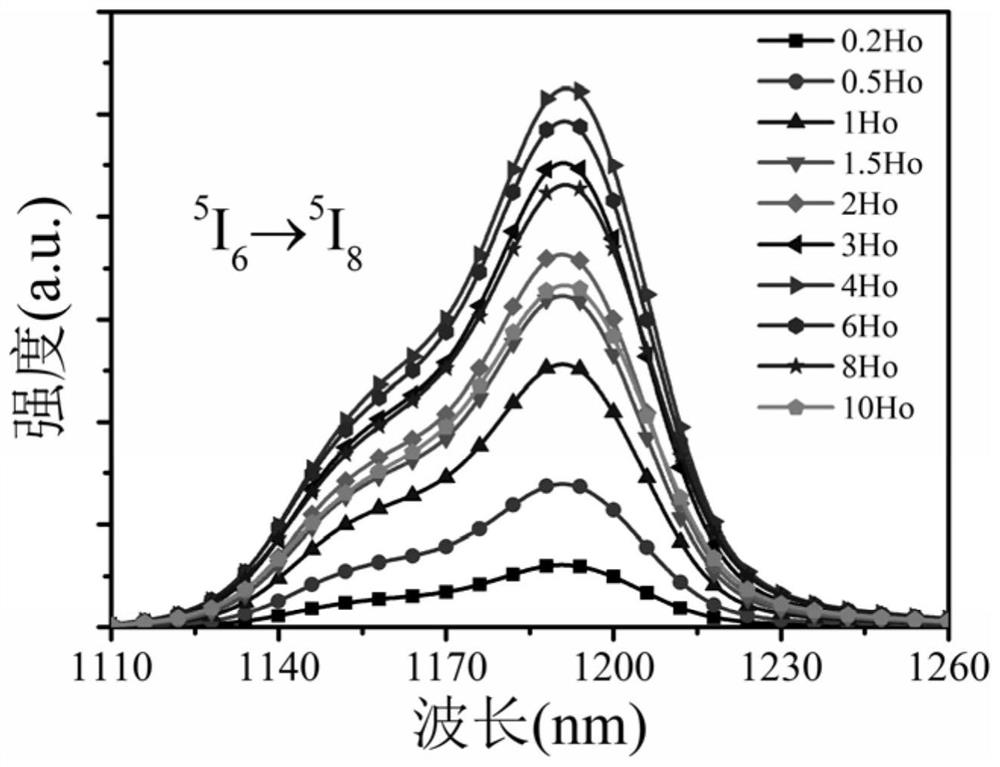

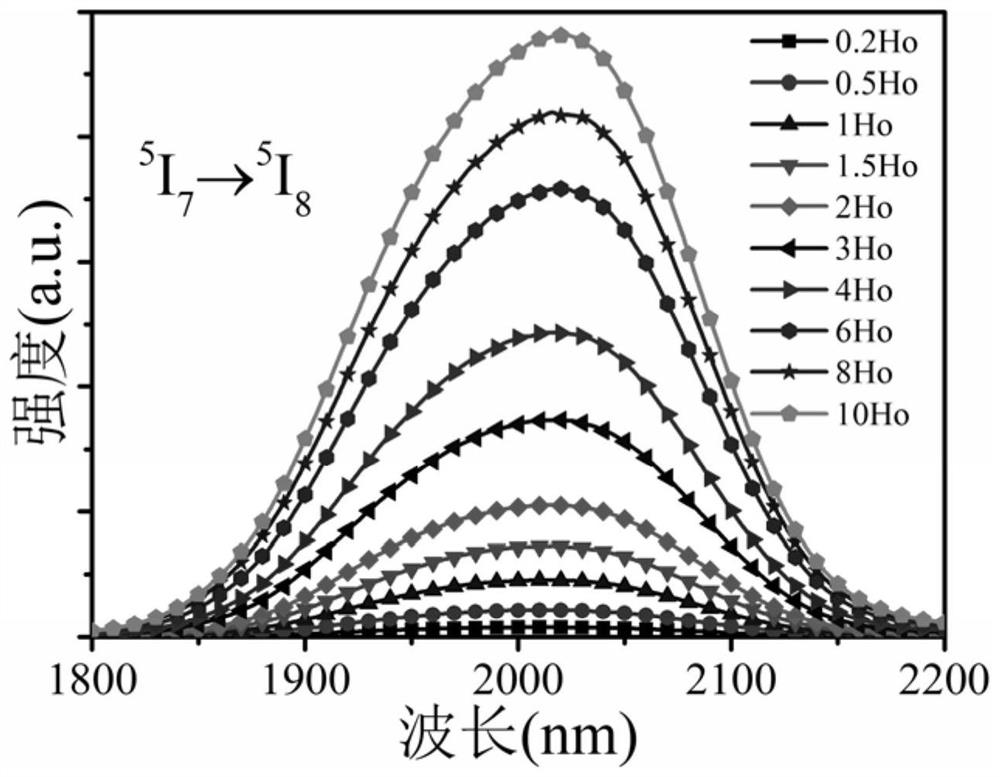

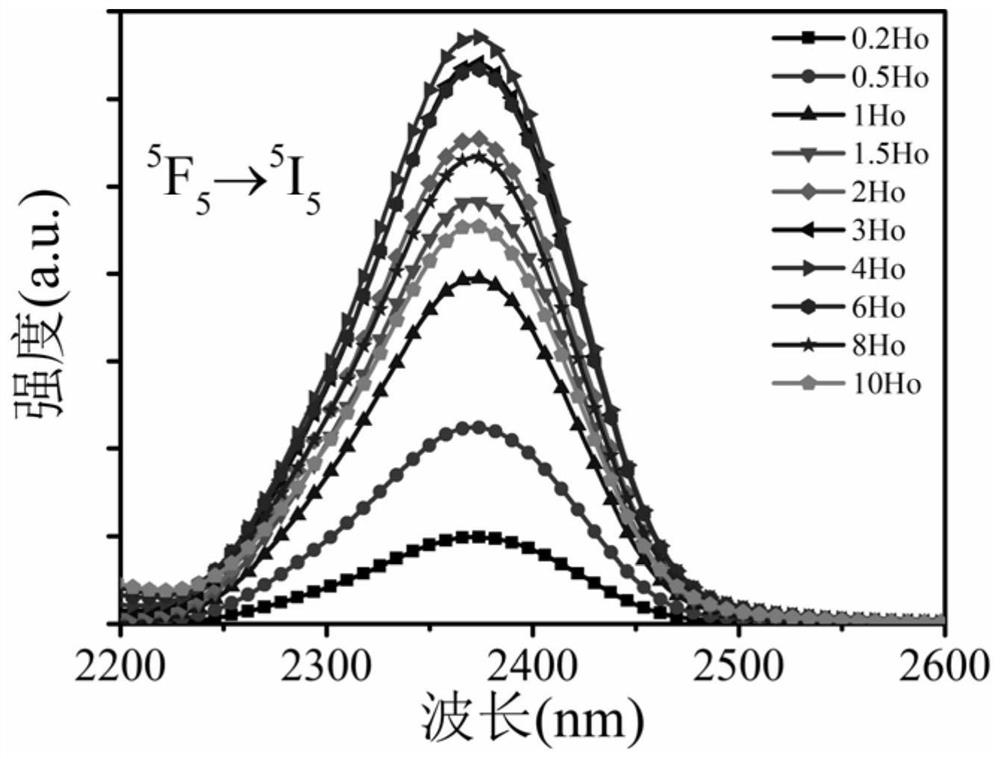

[0029] 4. Using a 638nm semiconductor laser to excite, set its power to 1.5W, and test the fluorescence spectra of fluoroaluminum glasses doped with different concentrations of Ho3+ ions at 1.2μm, 2.0μm, 2.4μm, 2.9μm and 3.9μm.

[0030] The selected fluoroaluminum glass component and Ho in the present invention 3+ Ions, the mid-infrared fluorescence emission of 1.2μm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com