Bubble point pressure testing method for underground high-pressure water sample and testing device of testing method

A technology of bubble point pressure and testing method, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc. It can solve the problems that the judgment result is an estimated value and affects the development of water-soluble gas, etc., to achieve accurate and reliable geological basis, and to provide geological Basis, operation calculation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

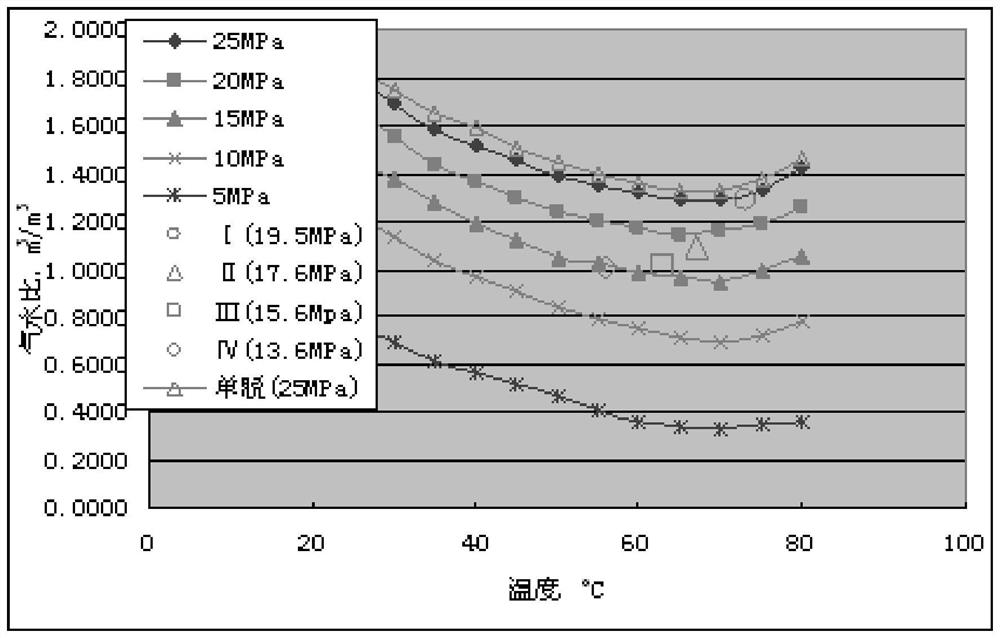

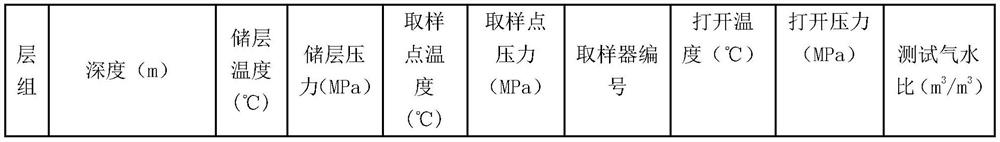

[0031] The method for testing bubble point pressure of downhole high-pressure water samples comprises the following steps: (a) connecting the downhole sampler to the inlet and outlet pipelines and the gate, heating the working environment of the downhole sampler to the formation temperature of the sampling formation, and passing the outlet pipeline to Vacuum is drawn inside the downhole sampler; (b) inject formation water into the downhole sampler and gradually pressurize until both ends of the downhole sampler open automatically, and record the opening pressure; (c) place the downhole sampler vertically so that the outlet pipeline Located at the top, the gas-water separator and the gas meter are connected to the top outlet pipeline in sequence, and the gas is released several times with a fixed volume from the gas meter until the downhole sampler reaches atmospheric pressure and the gas meter is no longer automatically exhausted; record several times During the second deflatio...

Embodiment 2

[0033] The bubble point pressure test method of downhole high-pressure water samples, on the basis of Example 1, the method of heating the working environment in step (a) is: heating with a heating tape on the downhole sampler jacket. In step (c), the volume of gas released by each deflation at the gas meter is 50ml. It also includes sending the gas released from the outlet end of the gas meter to the chromatograph for testing. The remaining formation water in step (e) W 3 The measurement method is as follows: weigh the downhole sampler together with the joint and pipeline to obtain M1; blow the pipeline with nitrogen, dry the joint and sampler, and weigh again to obtain M2; W 3 =M1-M2. Before connecting the downhole sampler, the downhole sampler should also be tested for leaks with low-pressure gas: the downhole sampler must be under a low pressure of less than 2MPa for five minutes and the pressure drop should not exceed 0.01MPa.

[0034] Through this example, the downhol...

Embodiment 3

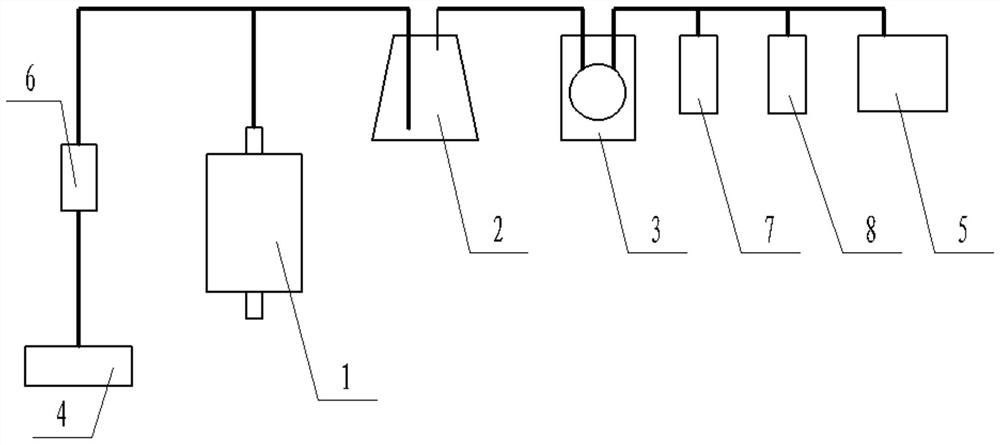

[0045] The bubble point pressure testing device for the downhole high-pressure water sample of any of the above-mentioned embodiments, such as figure 1 As shown, a downhole sampler 1 is included, the inlet line of the downhole sampler 1 is at the bottom, the outlet line of the downhole sampler is at the top, and the outlet line of the downhole sampler 1 is connected to the inlet end of the gas-water separator 2, and the gas-water The outlet end of the separator 2 is connected to the gas meter 3; it also includes a vacuum pump 4 connected to the outlet pipeline of the downhole sampler. The outlet end of the gas meter 3 is connected to a chromatograph 5 . A buffer container 6 is arranged between the downhole sampler and the vacuum pump. A density meter 7 and a viscometer 8 are also connected between the gas meter and the chromatograph.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com