Flexible planar micro energy storage device and its preparation method

A micro storage and device technology, applied in the field of energy storage devices, can solve the problems of no dispersion stability, easy to be oxidized, etc., and achieve the effects of excellent integration and scalability, improved electrochemical performance, and simple operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a flexible planar micro energy storage device, the specific steps of the method are as follows:

[0052] (1) Preparation of conductive paste for printing and electrode water-based paste

example 1

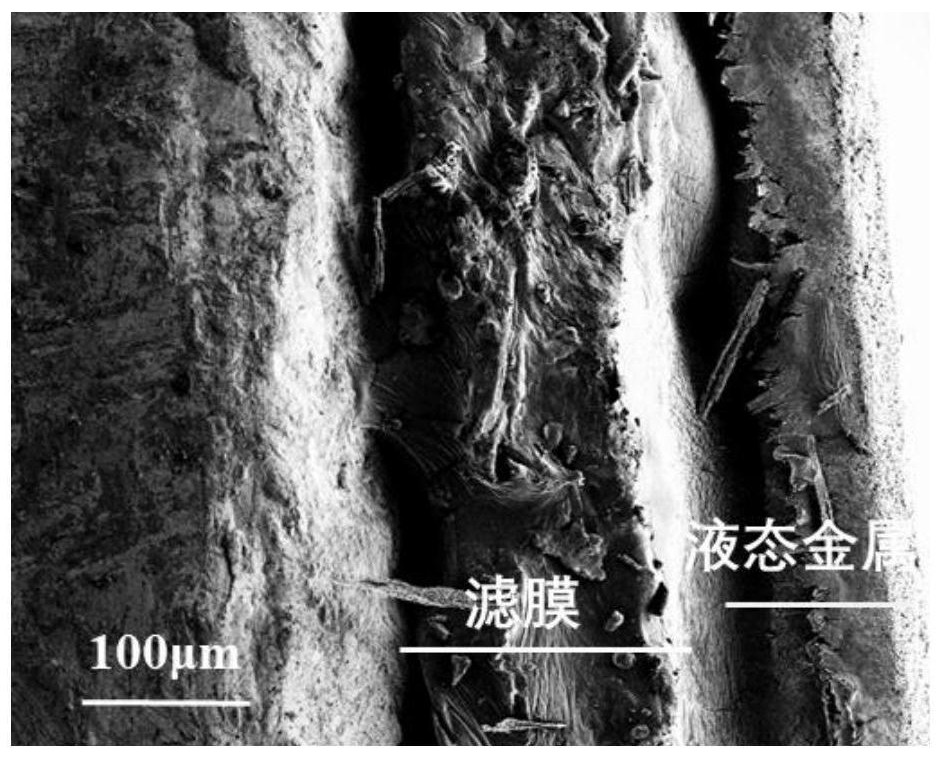

[0053] Coating and dispersing gallium-indium alloy and polyacrylamide (PAM) with silk fibroin aqueous solution to adjust the viscosity to obtain a conductive paste for conductive substrates with good dispersion stability. The specific preparation method is shown in Supplementary Example 1;

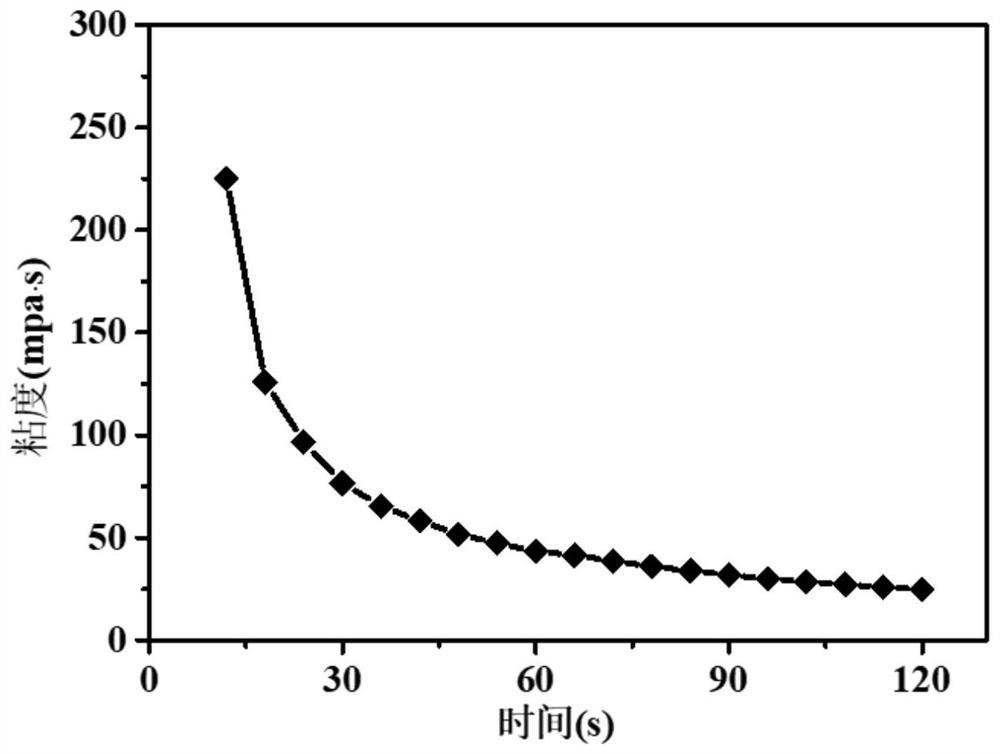

[0054] Graphene was used as the 2D flake active material and dissolved in deionized water, the viscosity was adjusted to 35.03mPa·s with polyacrylamide (PAM), and ultrasonically dispersed for 30min to obtain a water-based electrode paste with good rheological properties, which was used in subsequent procedures Accurately align the positive and negative poles of energy storage devices;

[0055] Electrode water-based paste formula: graphene 0.6%, polyacrylamide (PAM) 0.33%, the balance is deionized water, and the total weight of the electrode water-based paste is 100%.

[0056] (2) Printing and precise alignment

[0057] Using the conductive paste prepared in step (1), with the aid of a 1cm...

Embodiment 2

[0069] A preparation method for constructing a 3D array graphene-based micro-supercapacitor by screen printing technology, the specific steps of the method are as follows:

[0070] (1) Preparation of conductive paste for printing and electrode water-based paste

[0071] Dissolve 1g of silk fibroin in 20g of deionized water to form silk fibroin aqueous solution, then add 2g of gallium-indium alloy for ultrasonic dispersion, so that the silk fibroin aqueous solution is coated and dispersed with gallium-indium alloy to form a stable conductive ink, and then use polyethylene oxide (PEO) to adjust the viscosity to 12.37mPa·s to obtain a conductive paste for conductive substrates with good dispersion stability.

[0072] Graphene is used as the active material, polyethylene oxide (PEO) is used to adjust the viscosity, and deionized water is used as the solvent to prepare the electrode water-based paste (see Supplementary Example 2 for the specific preparation method), which is used f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com