Steel, machine component, and connecting rod

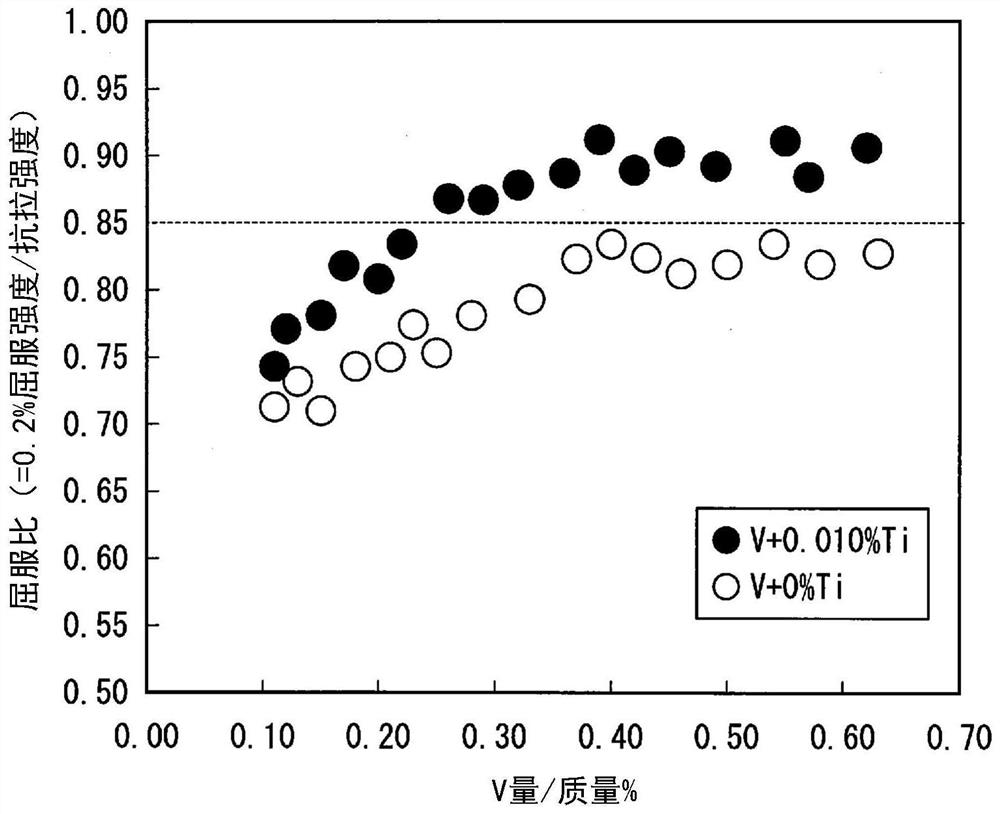

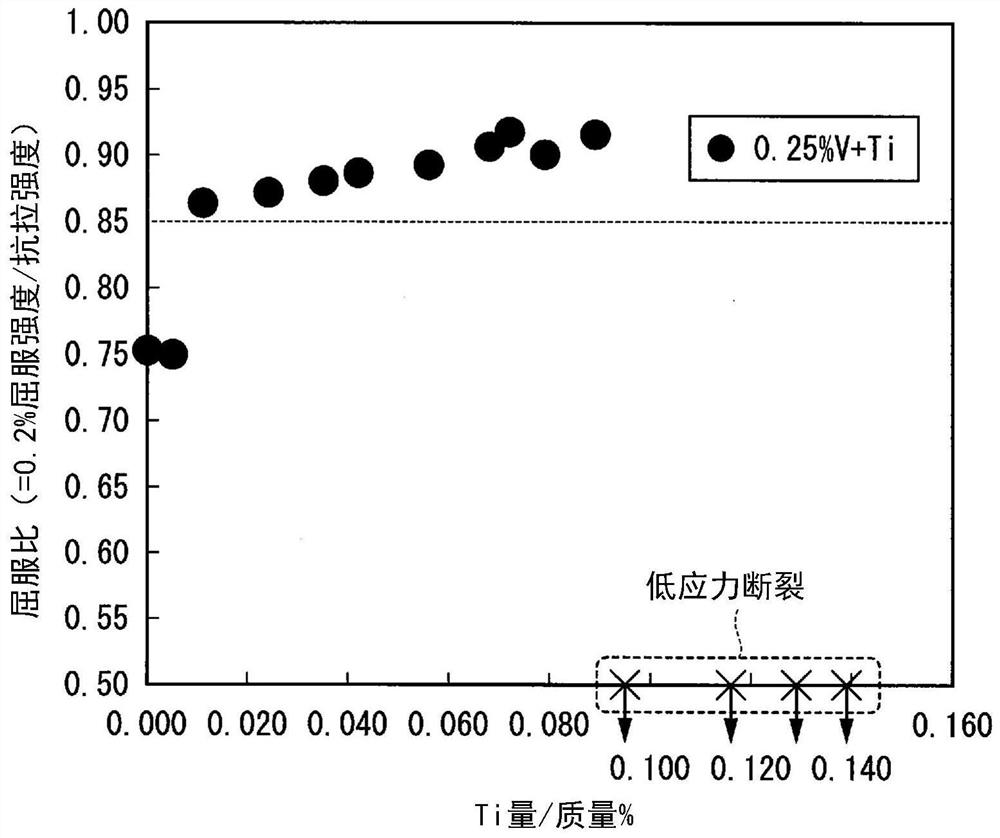

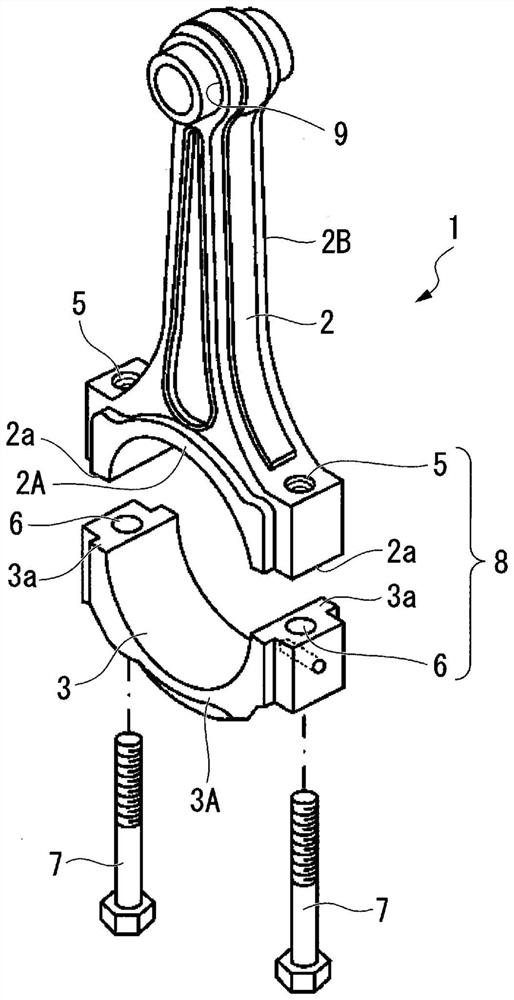

A technology of mechanical components and chemical components, applied in connecting rods, mechanical equipment, engine components, etc., can solve the problems of high strength and fracture surface fitting, and achieve excellent fracture separation and high yield ratio. , the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0135] The present invention is described in detail below through examples. It should be noted that these examples are examples for explaining the technical meaning and effects of the present invention, and do not limit the scope of the present invention.

[0136] Converter-smelted steels having the compositions shown in the following Tables 1-1 and 1-2 were produced by continuous casting, and rolled raw materials of 162 mm square were produced through soaking diffusion treatment and blooming process as needed. Next, after heating the rolling raw material to 950 degreeC, the steel was made into the shape of the bar steel with a diameter of 56 mm by hot rolling. Underlined values in Table 1-1 and Table 1-2 are values outside the range of the present invention. In addition, the symbol "-" in Table 1-1 and Table 1-2 shows that the element related to this symbol was not added.

[0137] Next, in order to investigate the microstructure and mechanical properties, a test piece c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap