Nut embedding and detecting tool jig

A technology for detecting tooling and fixtures, applied in measuring devices, manufacturing tools, metal processing, etc., can solve the problems of low embedded work efficiency, achieve full automation and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

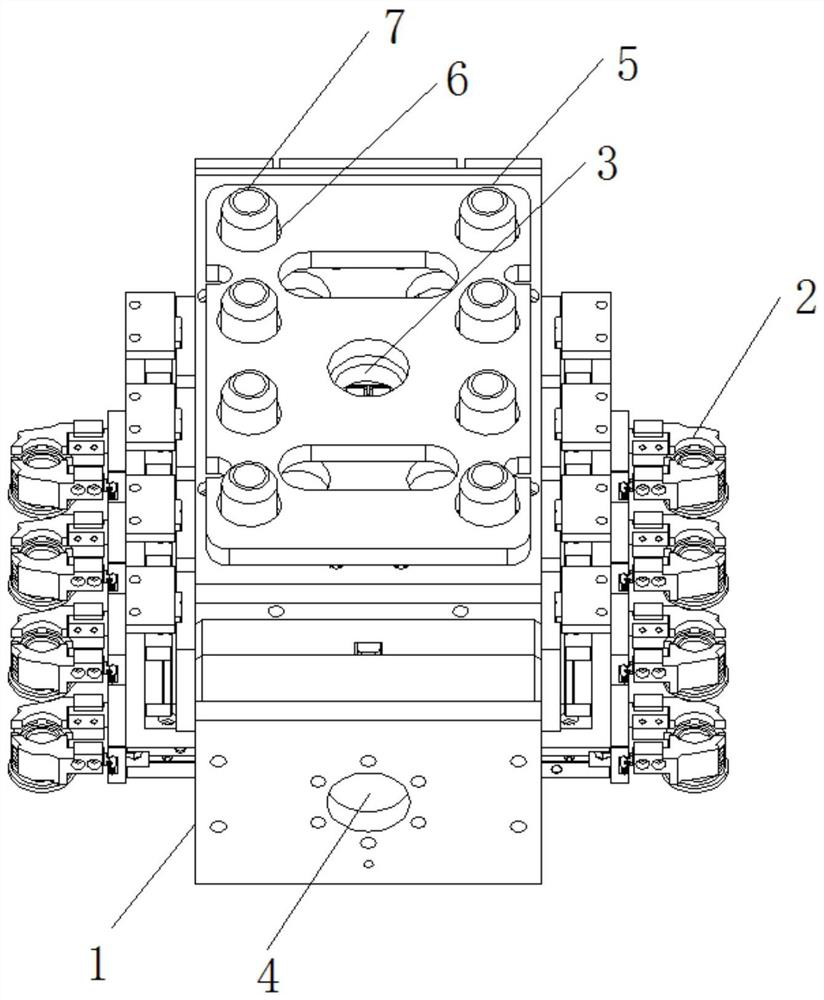

[0014] Please refer to figure 1 As shown, a nut embedding and detection tooling jig includes a jig main body 1, a number of evenly distributed nut clips 2 are installed on both sides of the jig main body 1, and the upper and lower ends of the jig main body 1 are set There is a No. 1 connecting hole 3, and the front and rear ends of the fixture body 1 are provided with a No. 2 connecting hole 4. The No. 1 connecting hole 3 is connected with a rotating shaft that can drive the fixture body 1 to rotate 180 degrees. The connection hole 4 is connected with a turning shaft that can drive the jig main body 1 to turn over 90 degrees. One side of the jig main body 1 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com