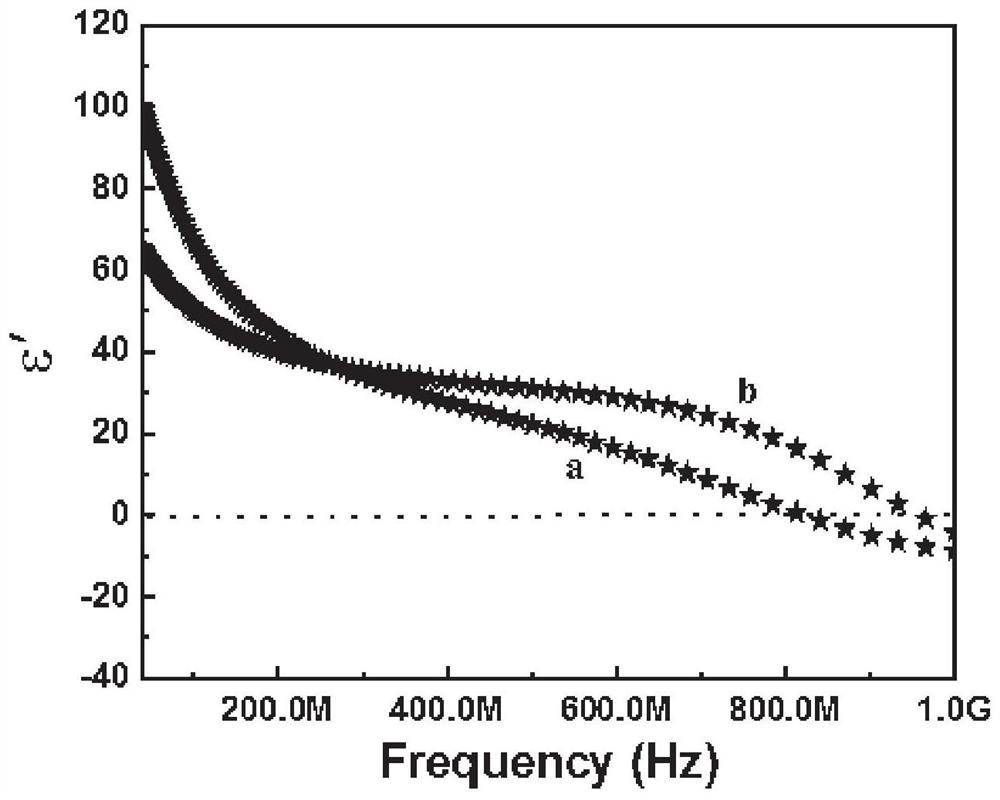

A preparation method of boron-doped graphene composite material and its application as negative dielectric material

A composite material and boron doping technology, which is applied in the field of preparation of boron-doped graphene negative dielectric composite materials, can solve the problems of limiting the application of metal negative dielectric composite materials, unfavorable impedance matching, and large negative value of metals, etc., to achieve The effect of simple preparation method, stable process and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] In the first aspect of the present invention, a method for preparing a boron-doped graphene composite material is provided, the preparation method comprising the following steps: adding boric acid to the graphene oxide dispersion liquid to disperse to obtain a uniform dispersion liquid, and the dispersion liquid is hydrothermally react to obtain boron-doped graphene powder; add phenolic resin to the boron-doped graphene powder and grind to obtain composite powder; the composite powder is formed by mechanical pressing to form the boron-doped graphene composite material.

[0024] Preferably, the concentration of the graphene oxide dispersion is 4-6 mg / ml.

[0025] Preferably, the boric acid is added to the graphene oxide dispersion and dissolved by ultrasonication, and the ultrasonication time is 4-6 hours. Further preferably, the ultrasonic time is 5 hours.

[0026] Preferably, the temperature of the hydrothermal reaction is 140-180° C., and the reaction time is 2-4 hou...

Embodiment 1

[0049] In the present embodiment, a kind of preparation method of boron-doped graphene composite material is provided, and described preparation method comprises the following steps:

[0050] S1. Prepare graphene oxide dispersion: disperse graphene oxide (GO) in deionized water to obtain a GO dispersion with a solution concentration of 5 mg / ml;

[0051] S2. Add boric acid (H 3 BO 3 ): put a certain mass of H 3 BO 3 Place in the GO dispersion prepared in step S1 and sonicate for dissolution; the sonication time is 5h;

[0052] S3. hydrothermal treatment: the H prepared in step S2 3 BO 3 The mixed solution with the GO dispersion liquid was transferred to the inner tank of the reactor, and heated at 160°C for 3 hours;

[0053] S4. Centrifugal washing: The boron-doped graphene hydrogel obtained by the hydrothermal reaction in step S3 is subjected to centrifugal washing treatment to obtain a boron-doped graphene suspension; the centrifugal speed is 3000rpm, and the centrifuga...

Embodiment 2

[0058] In the present embodiment, a kind of preparation method of boron-doped graphene composite material is provided, and described preparation method comprises the following steps:

[0059] S1. Prepare graphene oxide dispersion: disperse graphene oxide (GO) in deionized water to obtain a GO dispersion with a solution concentration of 4 mg / ml;

[0060] S2. Add boric acid (H 3 BO 3 ): put a certain mass of H 3 BO 3 Place in the GO dispersion prepared in step S1 and sonicate for dissolution; the sonication time is 4h;

[0061] S3. hydrothermal treatment: the H prepared in step S2 3 BO 3 The mixed solution with the GO dispersion liquid was transferred to the inner tank of the reactor, and heated at 140°C for 4 hours;

[0062] S4. Centrifugal washing: The boron-doped graphene hydrogel obtained by the hydrothermal reaction in step S3 is subjected to centrifugal washing treatment to obtain a boron-doped graphene suspension; the centrifugal speed is 2000rpm, and the centrifuga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com